Outer attached type high-rise building goods hoisting system

A high-rise building and lifting system technology, which is applied to elevators, conveyors, elevators, etc. in buildings, can solve problems such as no solutions, and achieve the effects of less preparation work, easy installation, and simple working procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

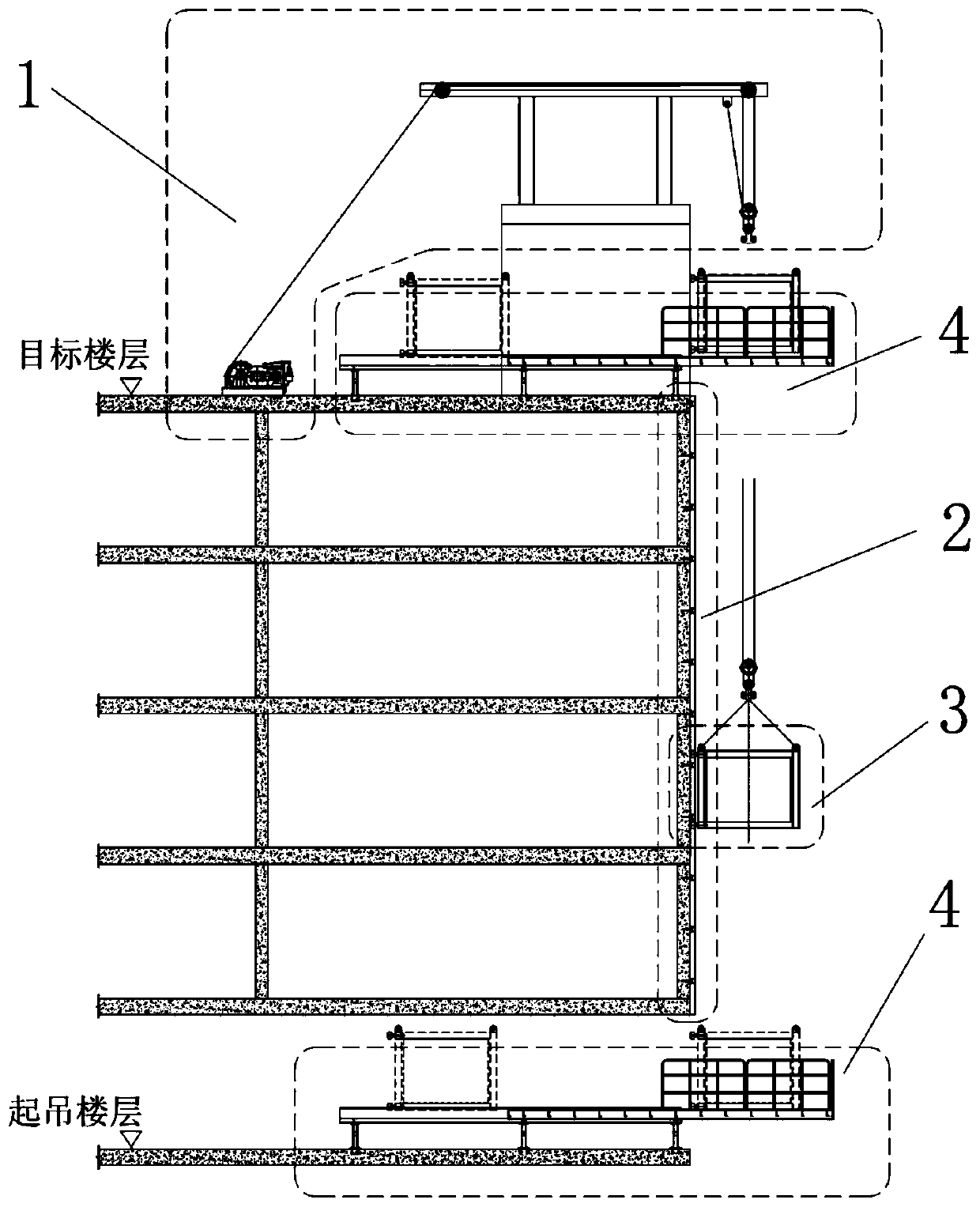

[0026] see figure 1 One embodiment of the present invention's attached high-rise building lifting system includes a winch lifting system 1 , a lifting track system 2 , a lifting frame system 3 and a mobile platform system 4 .

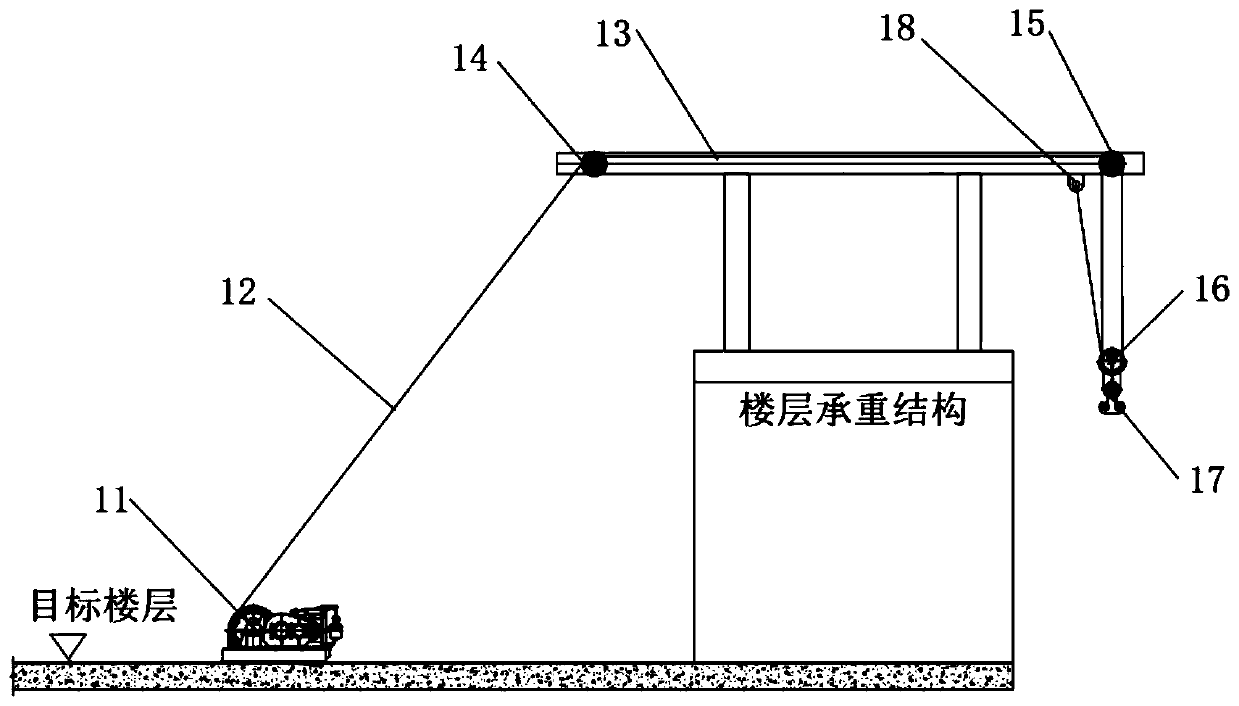

[0027] Such as figure 2 As shown, the winch hoisting system 1 includes a winch 11 , a wire rope 12 , a pulley frame 13 , a guide pulley 14 , a fixed pulley 15 , a movable pulley 16 , a hook set 17 , and a wire rope fixed end 18 . The hoist 11 is fixed on the floor at the top of the building by expansion bolts; the hoist 11 is provided with double brakes, and the clamp brake of the brake motor and the reel; the hoist 11 is provided with a stall protection sensor to ensure that Brake immediately when the hoist speed is abnormal. Fixed pulley 15, movable pulley 16 are fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com