Bucket elevator

A bucket elevator and hopper technology, which is applied to conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of prone to deviation, high precision requirements, and complex structure of the quantitative feeding device, so as to avoid deformation. Damage, avoid material accumulation, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

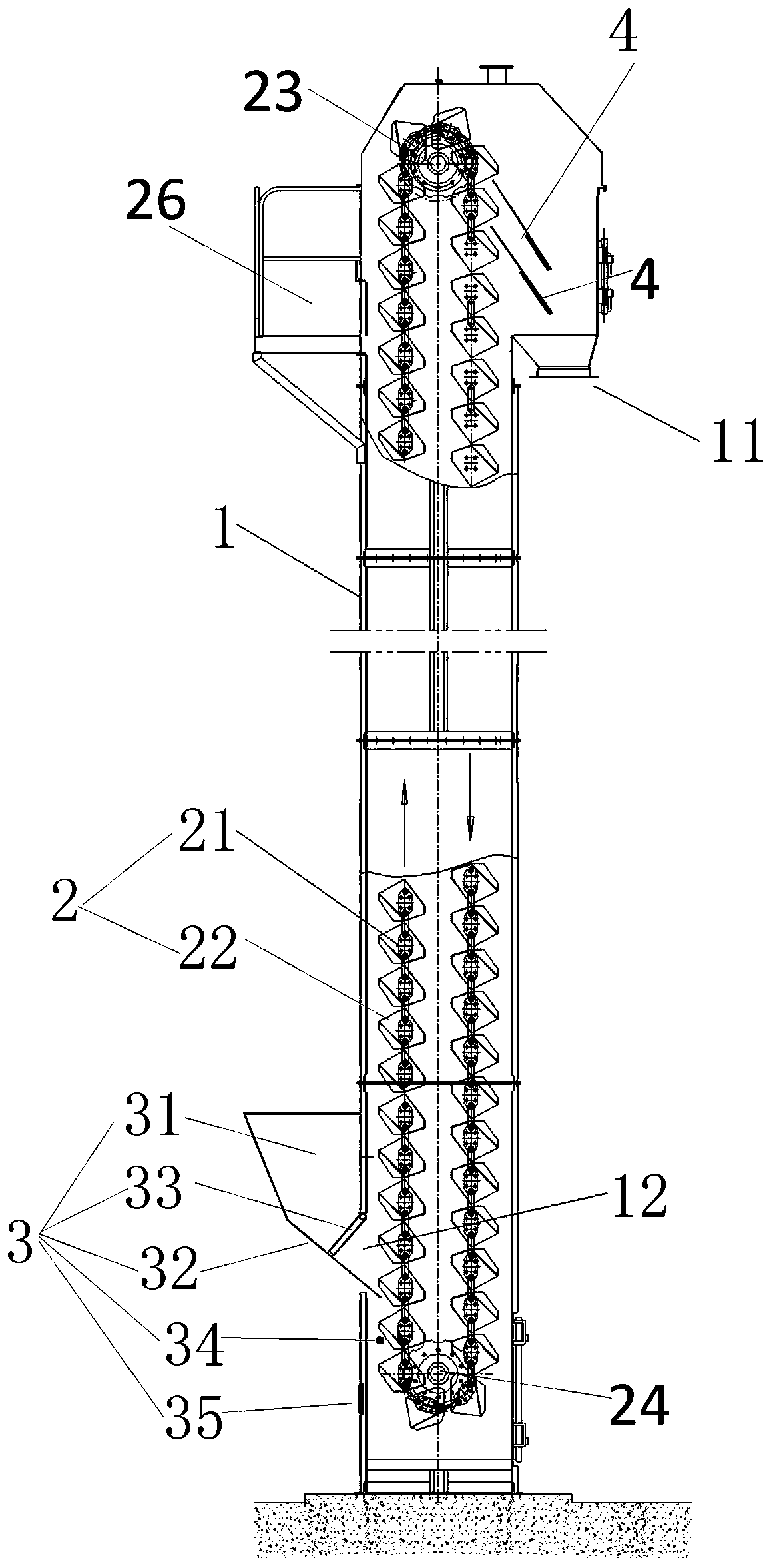

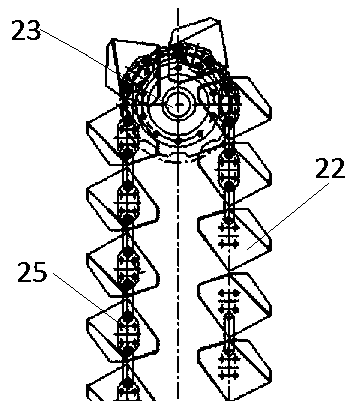

[0034] see figure 1, a bucket elevator, including a vertical shell 1, a hopper assembly 2 for lifting materials arranged in the shell 1, the top of the shell 1 is provided with a discharge port 11, and the bottom is provided with a feed mouth 12, the hopper assembly 2 includes a conveying part 21 and hoppers 22 evenly arranged on the conveying part 21, the feed inlet 12 is provided with a feed assembly 3 capable of feeding the hopper 22 with an appropriate amount of intermittent feeding, The discharge port 11 is provided with a material guide soft plate 4 that can guide the material from the hopper 22 to the discharge port 11, and the feed assembly 3 includes a storage hopper 31, a feeder that communicates with the storage hopper 31 and the feed port 12. Channel 32, an electric door 33 that can be opened and closed at the connection between the storage hopper 31 and the feeding channel 32, a sensor 34 arranged in the housing 1, and a controller 35 electrically connected with t...

Embodiment 2

[0048] This embodiment is based on embodiment 1, and its technical scheme is basically the same as embodiment 1, the difference is:

[0049] see Figure 6 , the flexible board 4 includes a curved portion 42 at the upper end and a material dumped portion 43 at the lower end, the length of the curved portion 42 is a, and the value of a is 10 to 30 centimeters, the inclination between the curved portion 42 and the horizontal plane The angle is α, and the value of α is 15 to 45 degrees. The inclination angle between the discharge part 43 and the horizontal plane is β, and the value of β is 30 to 60 degrees. While ensuring that the material slides down smoothly, the bending part 42 is reduced. Due to the restoring force generated by the deformation, the hopper 22 can pass over smoothly.

Embodiment 3

[0051] This embodiment is based on embodiment 1, and its technical scheme is basically the same as embodiment 1, the difference is:

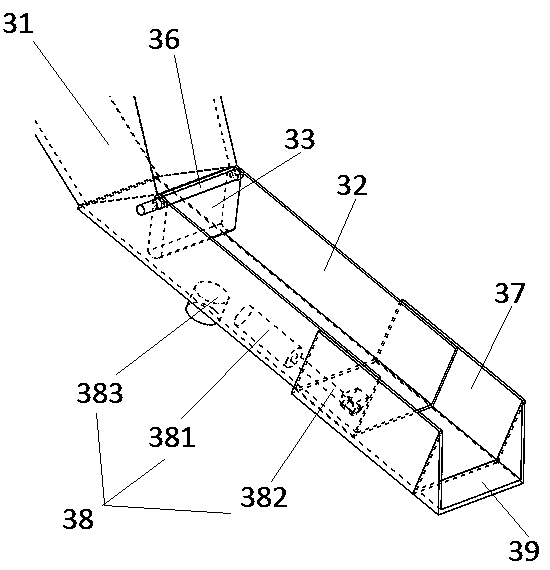

[0052] see Figure 7 , the inclination angle between the feed channel 32, the feed guide plate 37 and the horizontal plane is γ, the value of γ is 30 to 60 degrees, the length of the rubber guide plate 39 is b, and the value of b is 10 to 30 centimeters, the The inclination angle between the rubber guide plate 39 and the horizontal plane is δ, and the value of δ is 10 to 45 degrees. While ensuring that the material slides down smoothly, it reduces the restoring force of the rubber guide plate 39 due to deformation, so that the hopper 22 can pass over smoothly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com