Pneumatic tire

A technology of pneumatic tires and treads, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc., which can solve problems such as inability to meet the driving needs of all-season tires, and ensure wet handling and driving stability , snow driving stability and handling improvement, performance optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The purpose of this specific embodiment is to provide a pneumatic tire, which has excellent driving performance in dry, wet and snowy road conditions, and can fully meet the driving requirements of the vehicle in four seasons.

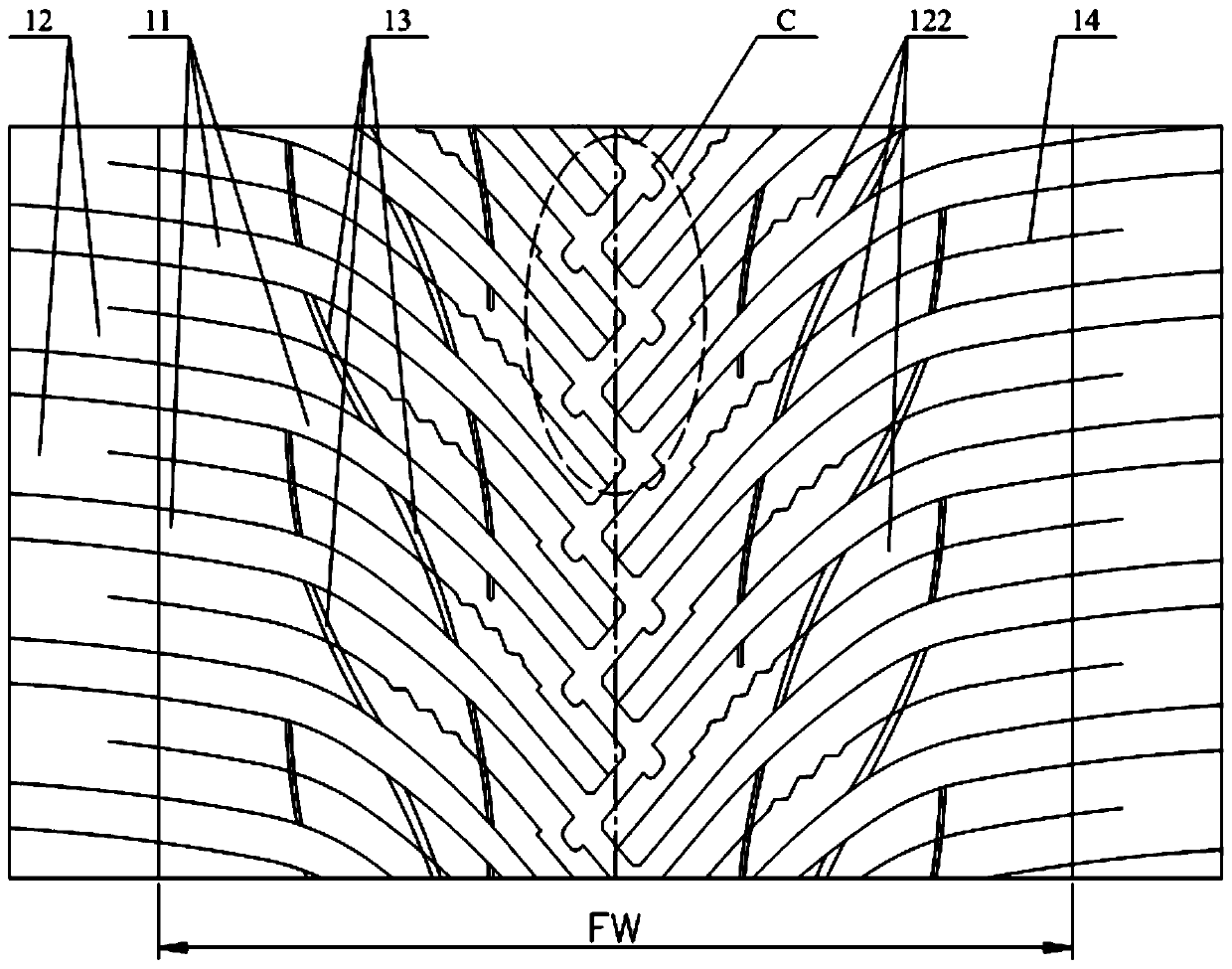

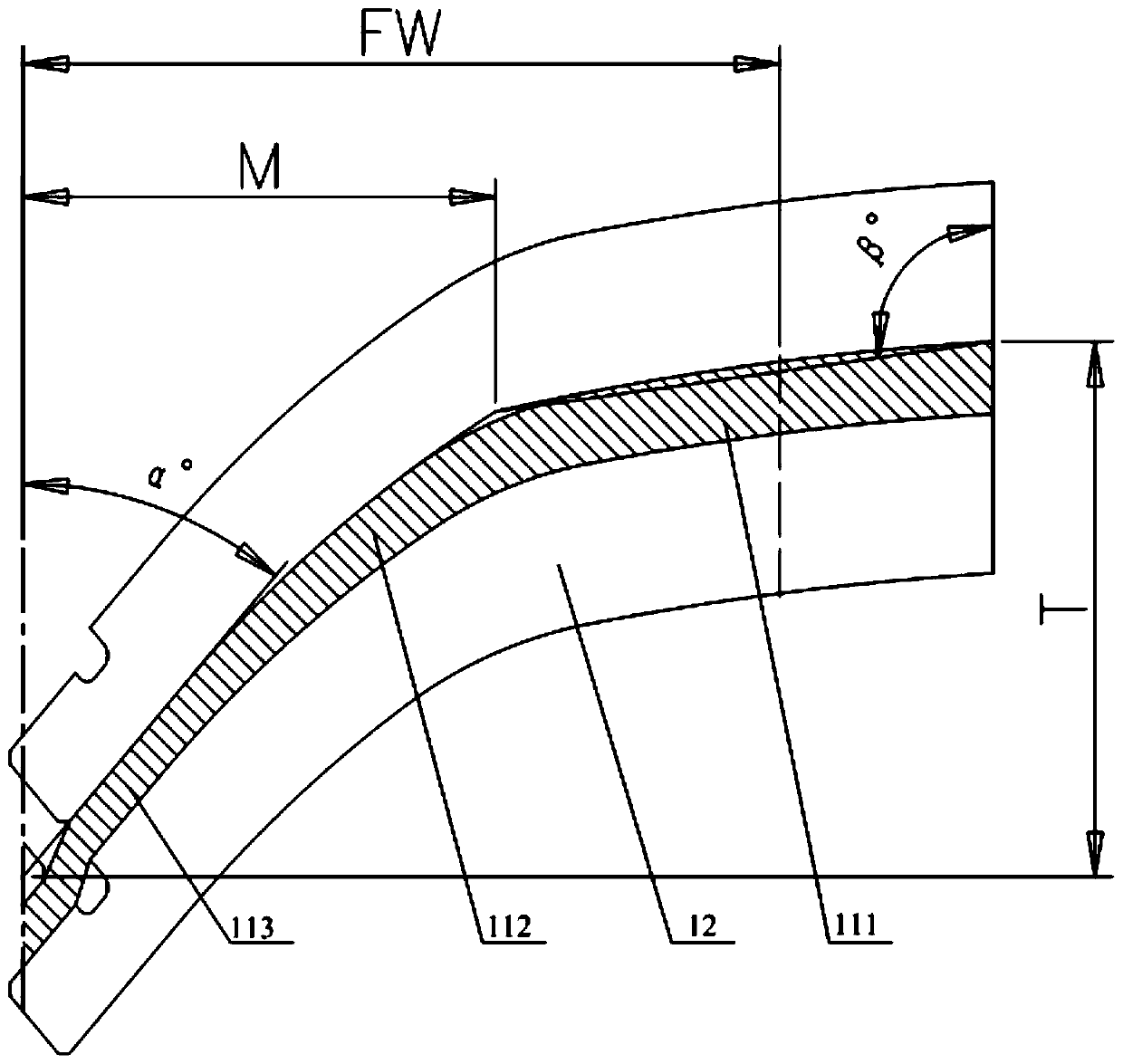

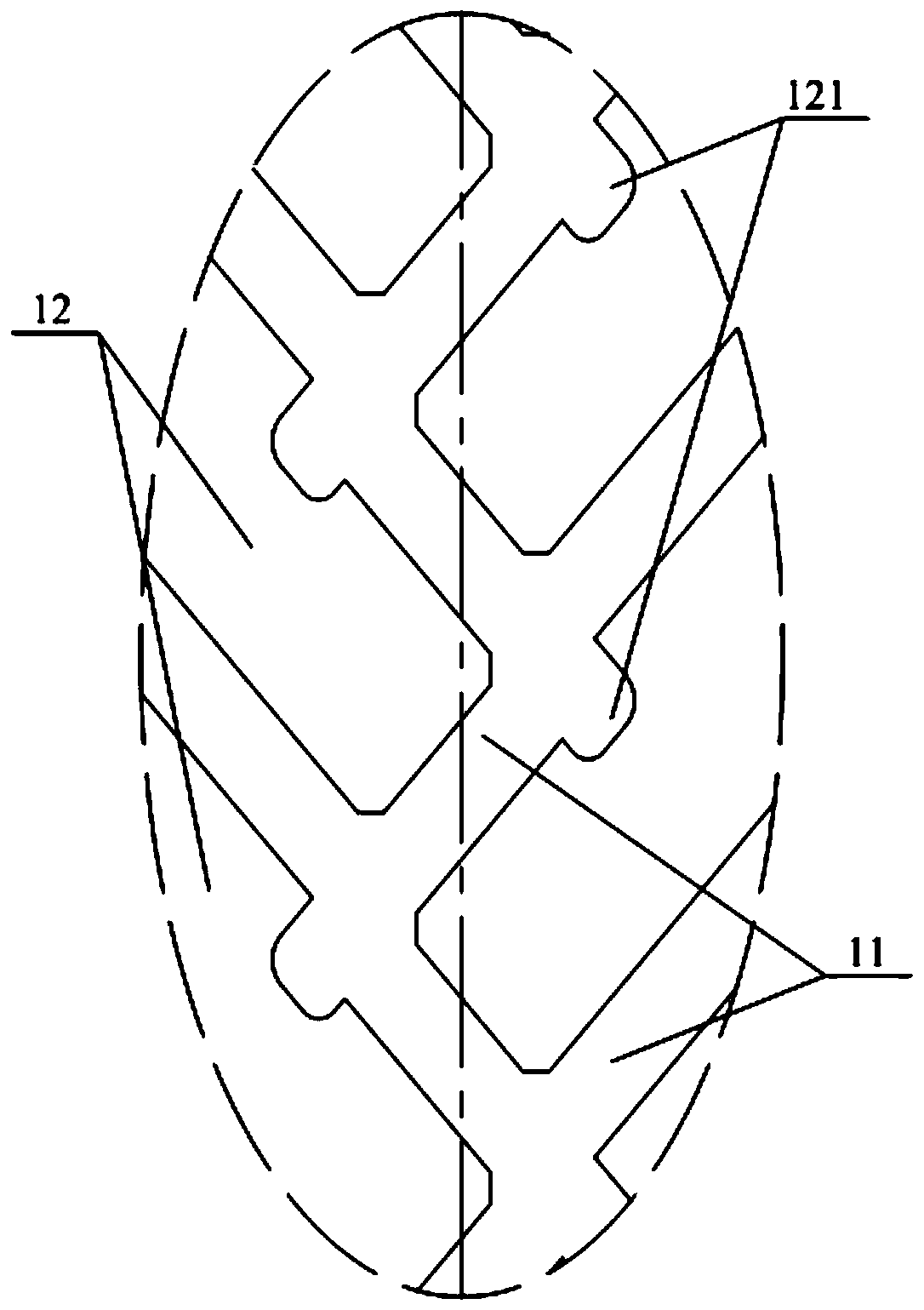

[0030] Please refer to Figure 1-Figure 8 , figure 1 It is a structural schematic diagram of the main tread part of the pneumatic tire provided in a specific embodiment of the present invention; figure 2 for figure 1 Schematic diagram of the structure of the middle main groove; image 3 for figure 1 The enlarged view of the local structure of part C in the middle; Figure 4 for figure 1 Schematic diagram of the position distribution of the middle longitudinal thin sipe; Figure 5 for Figure 4 Size comparison diagram of each part of the middle longitudinal thin sipe; Figure 6 for figure 1 Schematic diagram of the structure of the middle horizontal thin sipe; Figure 7 It is an axial schematic diagram of a partial structure of a pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com