Handheld type iron wire surface rust treatment device

A processing equipment, hand-held technology, applied in the direction of metal processing equipment, grinding/polishing equipment, portable grinding bed, etc., can solve the problem of inconvenient treatment of rust on the surface of iron wire, etc., to increase the contact friction area and ensure stable use , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

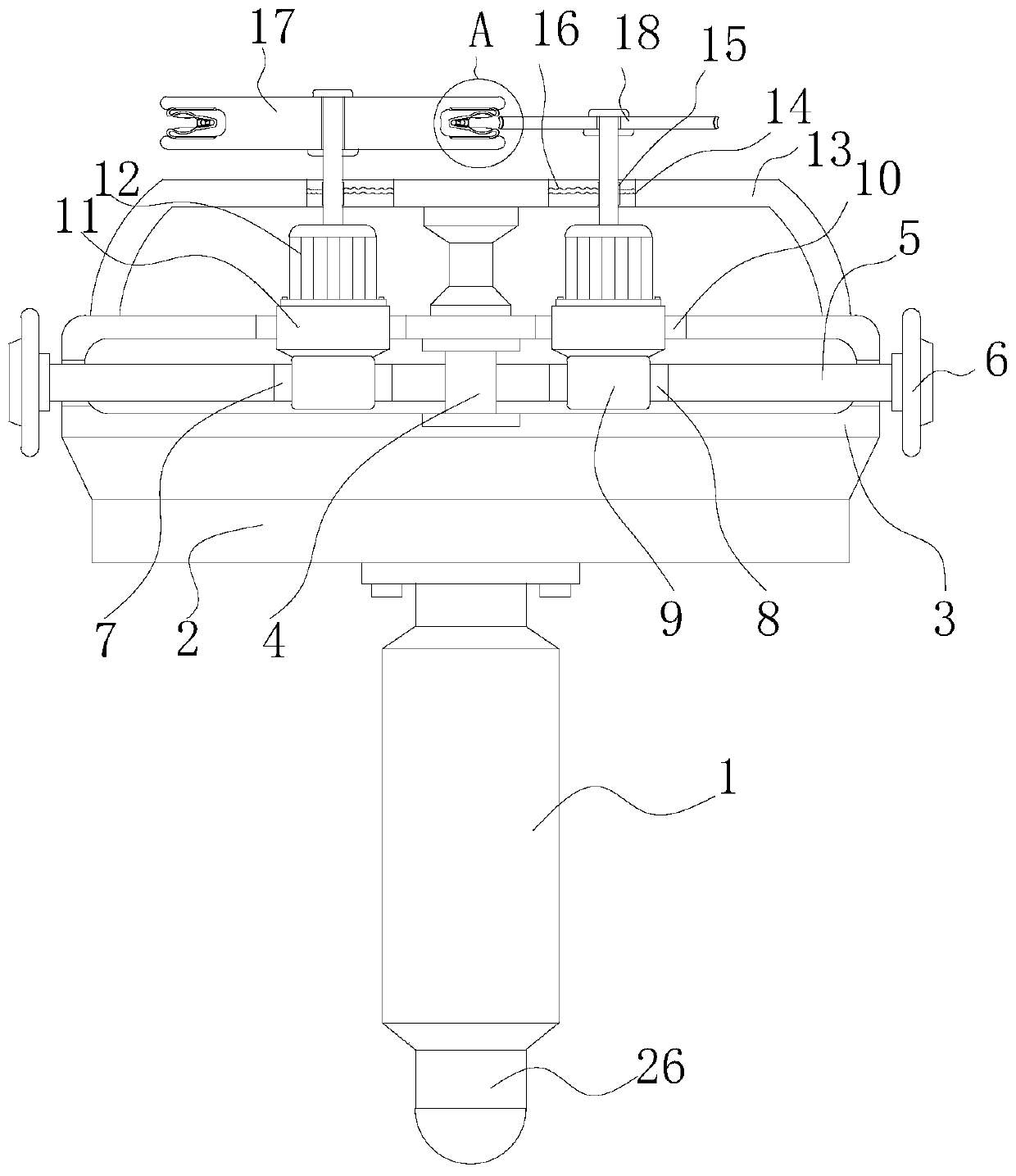

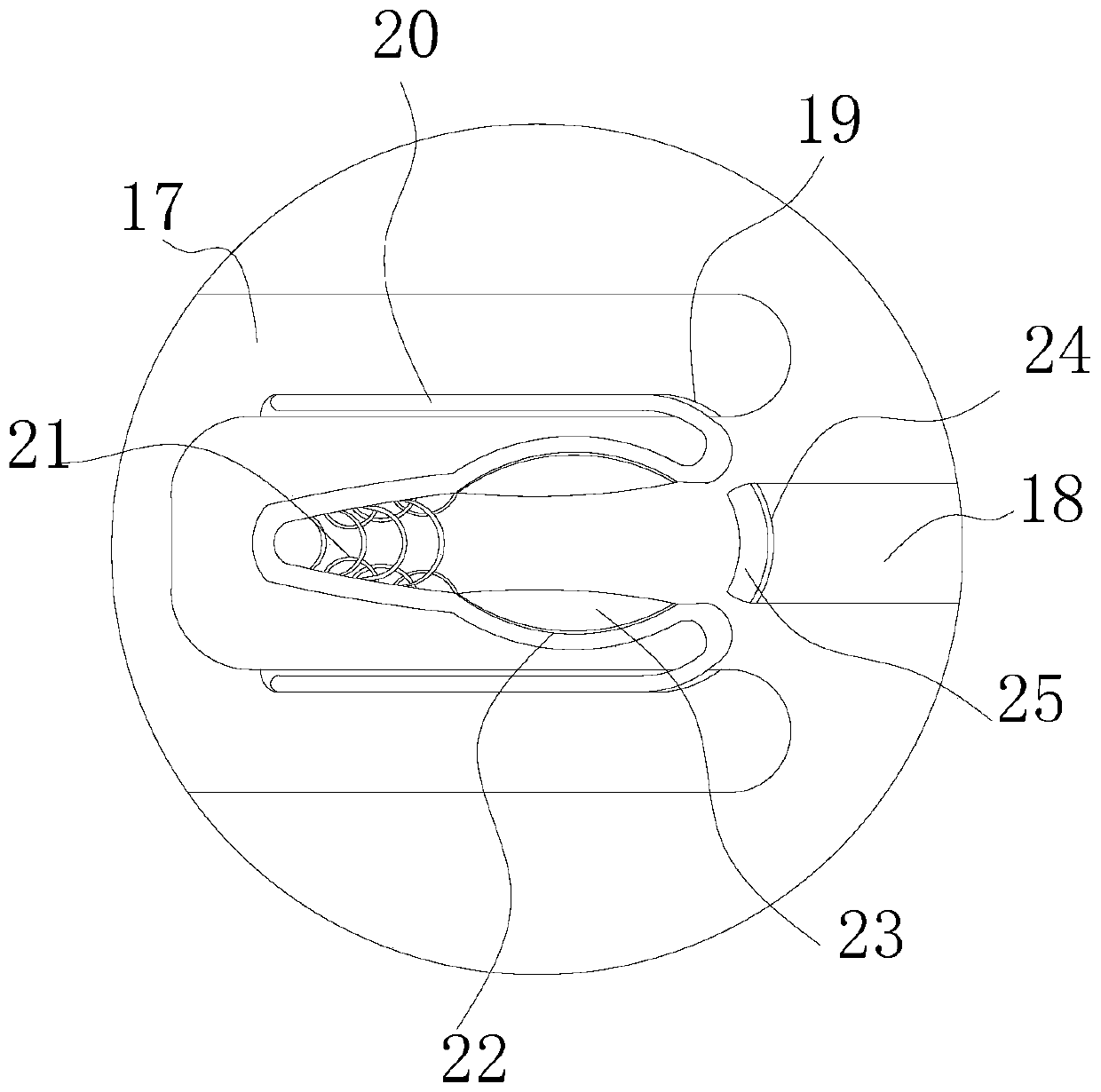

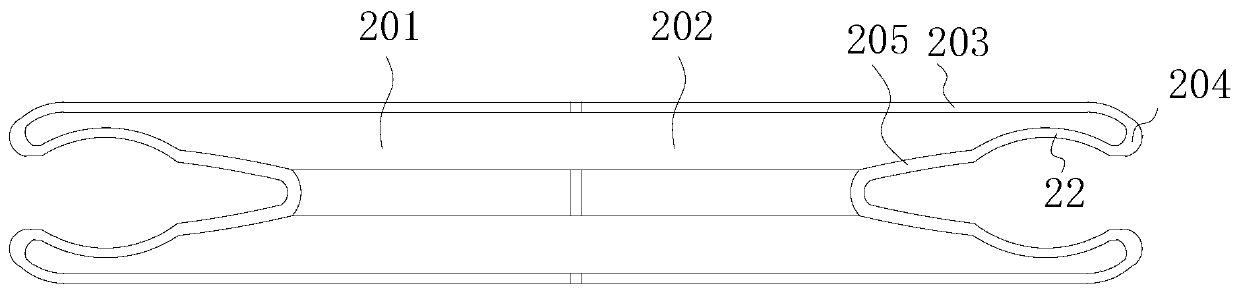

[0024] Such as Figure 1-3As shown, the present invention provides a technical solution: a hand-held iron wire surface rust treatment equipment, including a handle 1, a mounting base 2, a lateral adjustment box 3, an intermediate bearing 4, a horizontal polished rod 5, two star handles 6, Forward thread 7, reverse thread 8, ball nut 9, transverse movable groove 10, two transverse movable blocks 11, two micro motors 12, fixed frame 13, two transverse chute 14, two chute rings 15, Two telescopic rubber sheets 16, runner 17, pressing plate 18, inner ring installation groove 19 inner pressure ring 20, arc brush 21, storage groove 22, elastic rust removal sheet 23, fitting ring groove 24, rust removal sleeve 25 And the button switch 26, the installation base 2 is fixedly installed on the top of the handle 1, the horizontal adjustment box 3 is fixedly installed on the top of the installation base 2, the intermediate bearing 4 is fixedly installed on the inner bottom of the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com