Oil-free direct-driven vibrating screen

A vibrating screen and direct drive technology, applied in the field of screening, can solve the problems of increased manufacturing cost, heavy weight, limited installation space in the production workshop, etc., and achieve the effect of reducing installation space and complexity, less basic investment, and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

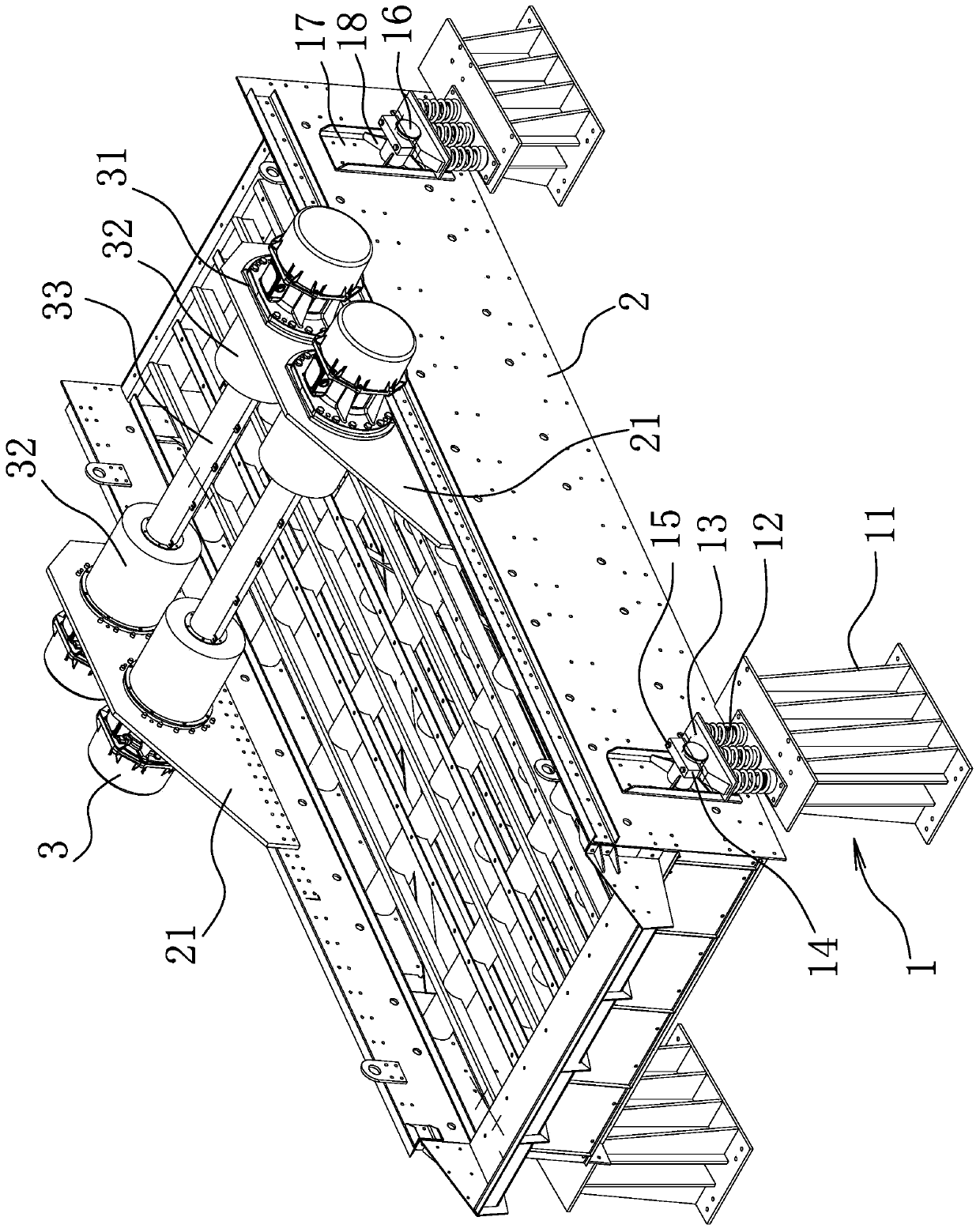

[0042] The following are specific embodiments of the invention and combined with the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0043] like Figure 1-3 As shown, the oil-free direct-drive vibrating screen includes a vibrating screen frame 2 fixed on an elastic support mechanism 1 and arranged obliquely. Specifically, the elastic support mechanism 1 includes four mounting brackets 11, and the mounting brackets 11 include lower mounting brackets The bottom plate and the upper mounting top plate located above the lower mounting bottom plate, the lower mounting bottom plate and the upper mounting top plate are connected by two spaced vertical vertical plates, and between the lower mounting bottom plate and the upper mounting top plate are also connected with each vertical vertical plate. Reinforcing risers attached to the outer surfaces of the panels.

[0044] A number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com