Self-cleaning high-efficiency sludge granulator

A self-cleaning and granulating machine technology, applied in sludge treatment, fixed/solidified sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of delaying production efficiency, decreasing granulation efficiency, affecting screen life, etc. problem, to achieve the effect of ingenious structure, improved service life and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

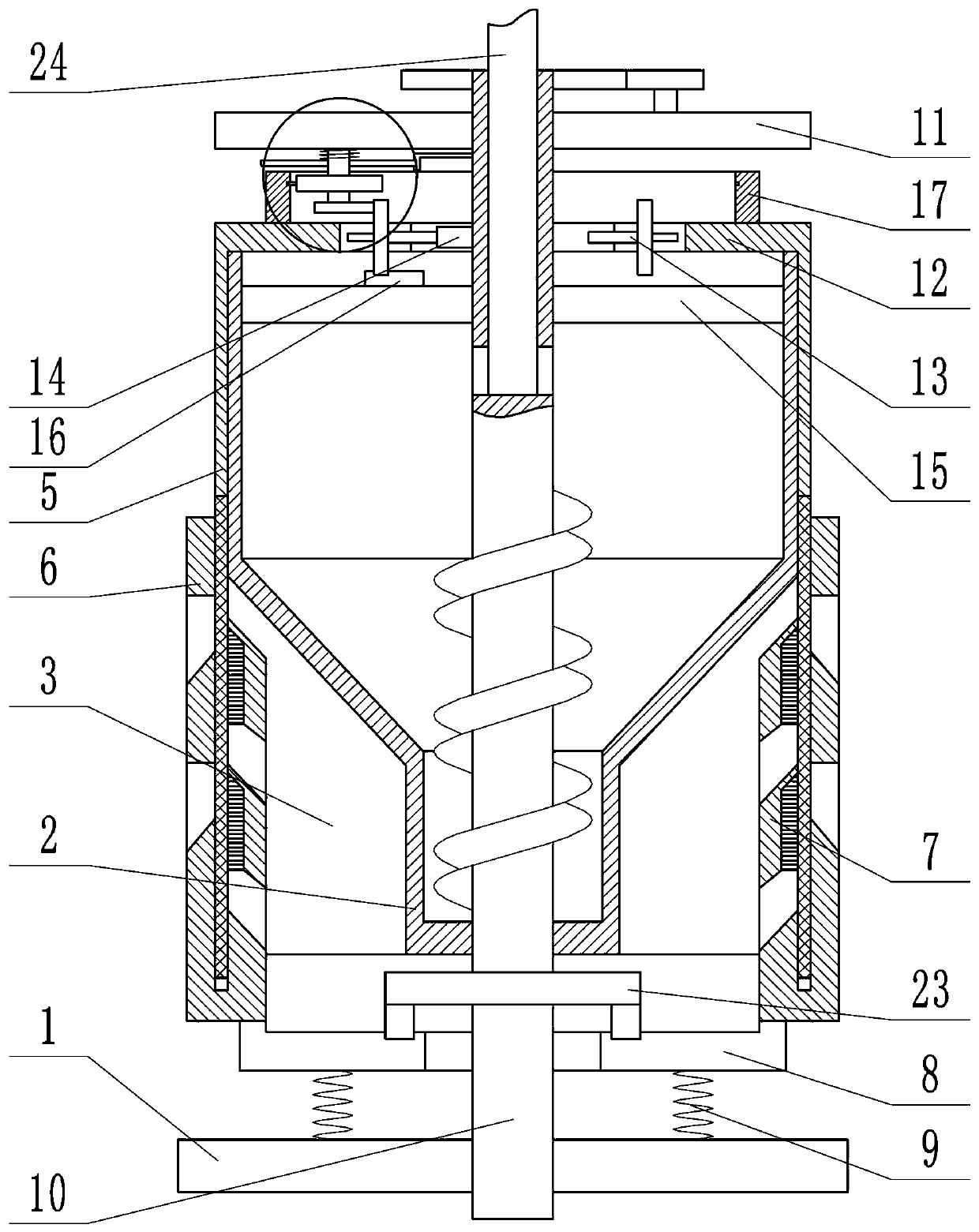

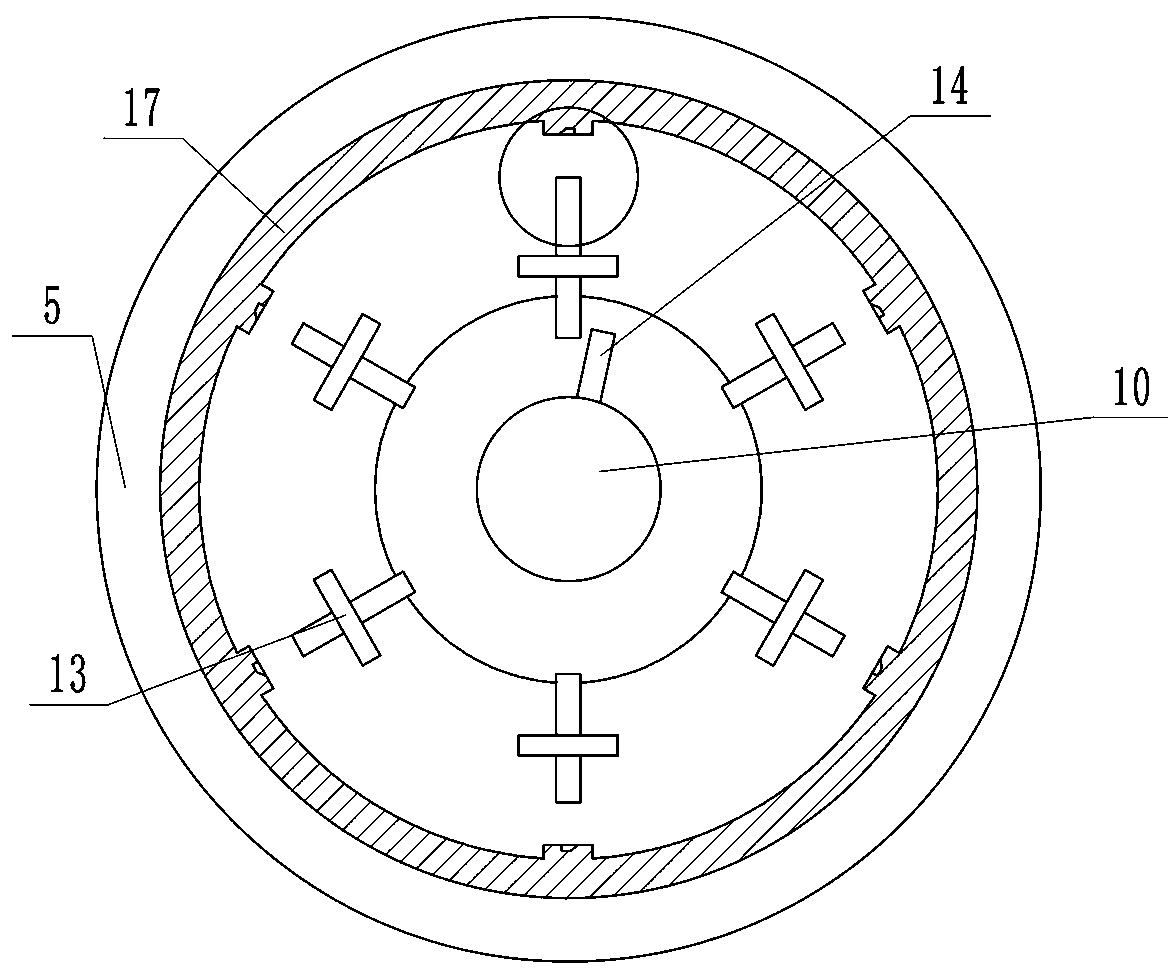

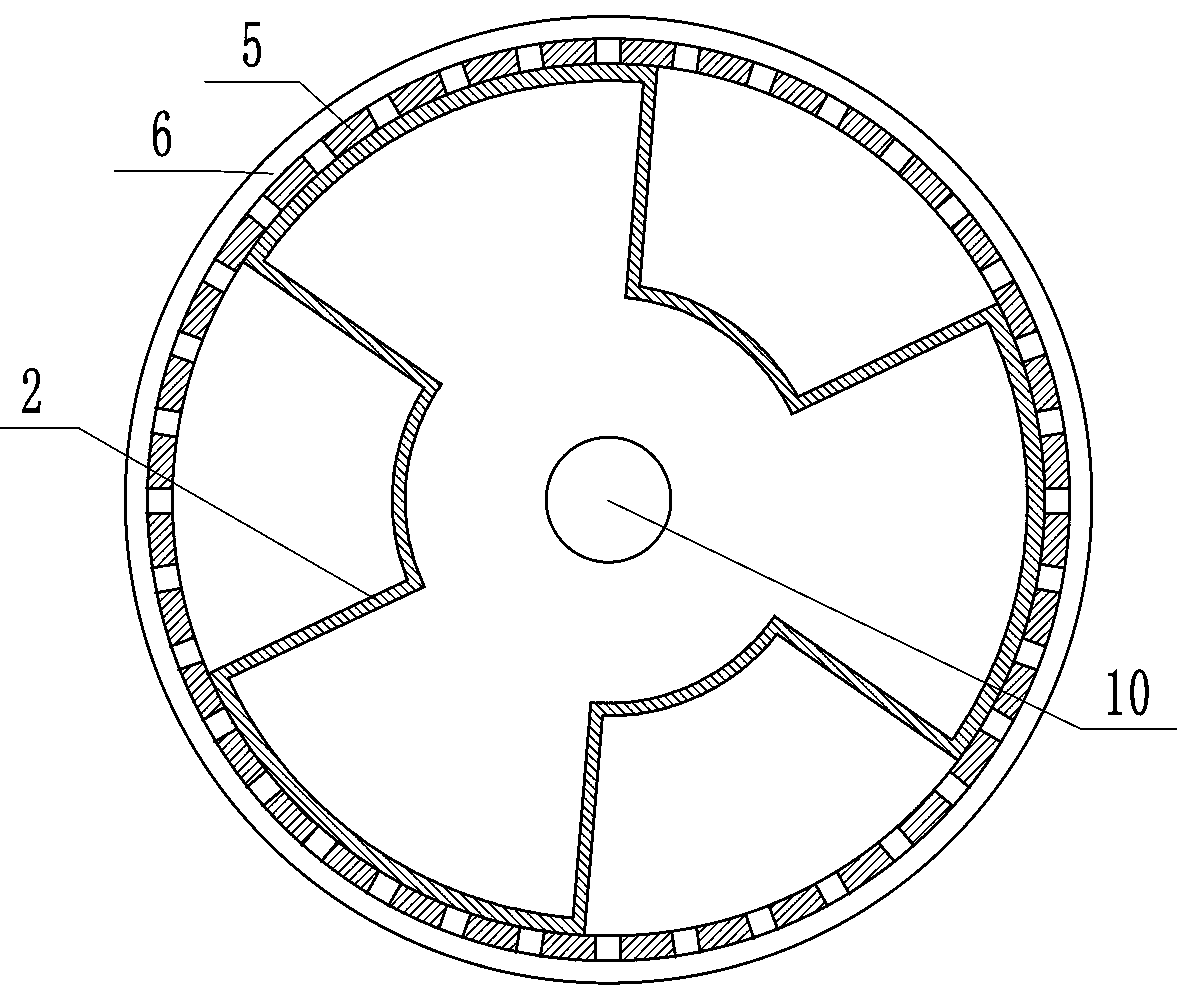

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] Depend on Figure 1-6 It can be seen that the present invention includes a horizontally placed bottom plate 1, a vertically placed cylinder 2 is arranged above the bottom plate 1, and a plurality of circumferentially evenly distributed depressions 3 are provided on the lower side wall of the cylinder 2. The non-recessed part of the wall is provided with a through groove 4 communicating with the inside of the cylinder 2, and a filter cartridge 5 that can rotate intermittently is set on the outer circle of the cylinder 2, and the inner surface of the filter cartridge 5 is in contact with the outer surface of the cylinder 2 Fitting, the lower end of the filter cartridge 5 is an open structure, the outer circle of the filter cartridge 5 is fitted with a scraper 6, the recessed part 3 is provided with a cleaning plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com