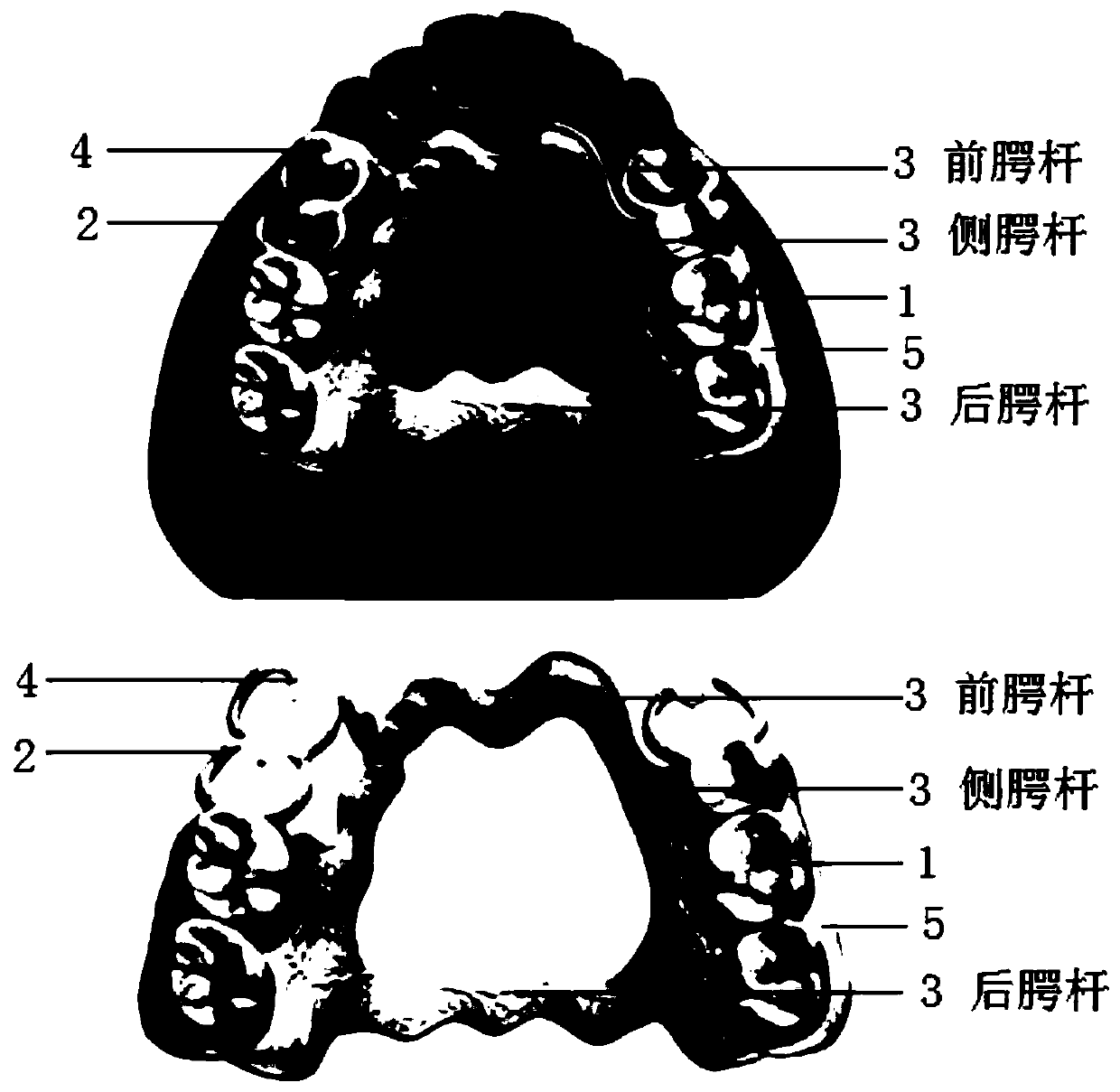

Personalized removable local dentures, and design method and manufacture method thereof

A design method and local technology, applied in the direction of additive manufacturing, manufacturing tools, metal processing equipment, etc., can solve the problems of errors, relying on clinical experience and manufacturing skills, complicated and complicated manufacturing process, etc., to achieve simplified manufacturing process, excellent physical and chemical properties, The effect of reducing the number of doctor visits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0037] The design method of a kind of personalized removable partial denture of the present invention, specifically implement according to the following steps:

[0038] Step 1. Place the required The tooth area of the rest is prepared; the standard of preparation is specifically, the preparation on the occlusal surface of the tooth Recess concave; The width of the rest recess is 1 / 3 of the buccal-lingual diameter of molars, or 1 / 2 of the buccal-lingual diameter of premolars; The height of the support recess is 1.3-1.6mm; The length of the rest recess is 1 / 4 of the mesial-distal diameter of molars, or 1 / 3 of the mesial-distal diameter of premolars; the axis angle is round and blunt;

[0039] Step 2. Use 3Shape software to scan the patient's edentulous jaw to obtain the oral data of the patient's edentulous jaw; or, prepare a plaster...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com