Mung bean hull breaking, separation and extraction device for dairy product processing

An extraction device and dairy product technology, which is applied in the field of dairy product processing mung bean shell breaking separation and extraction device, can solve the problems of high cost consumption, low efficiency, small contact surface of internal packaging, etc., and achieve the effect of high cost consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

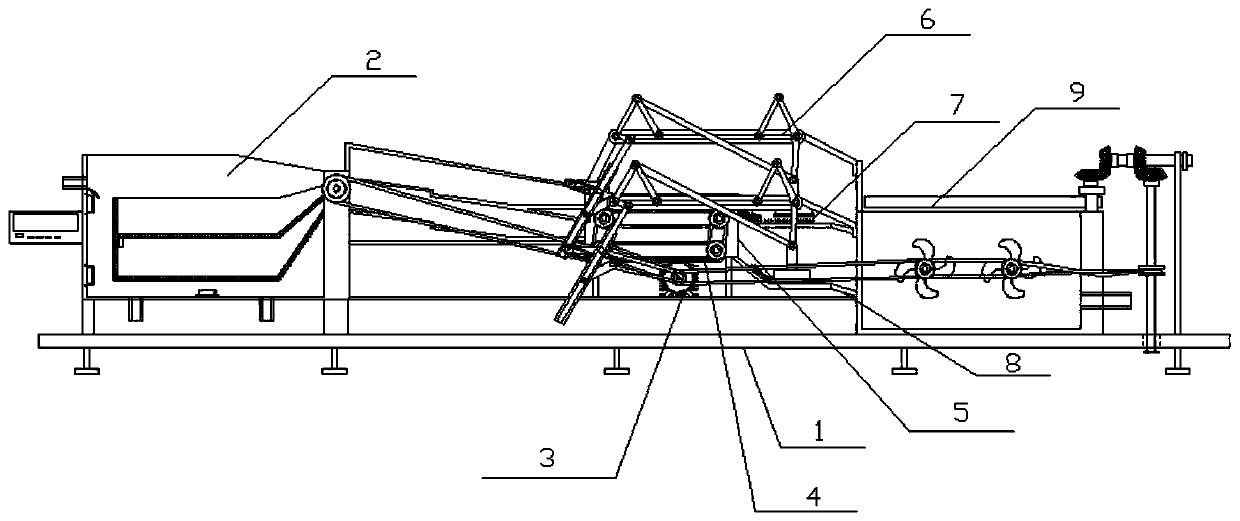

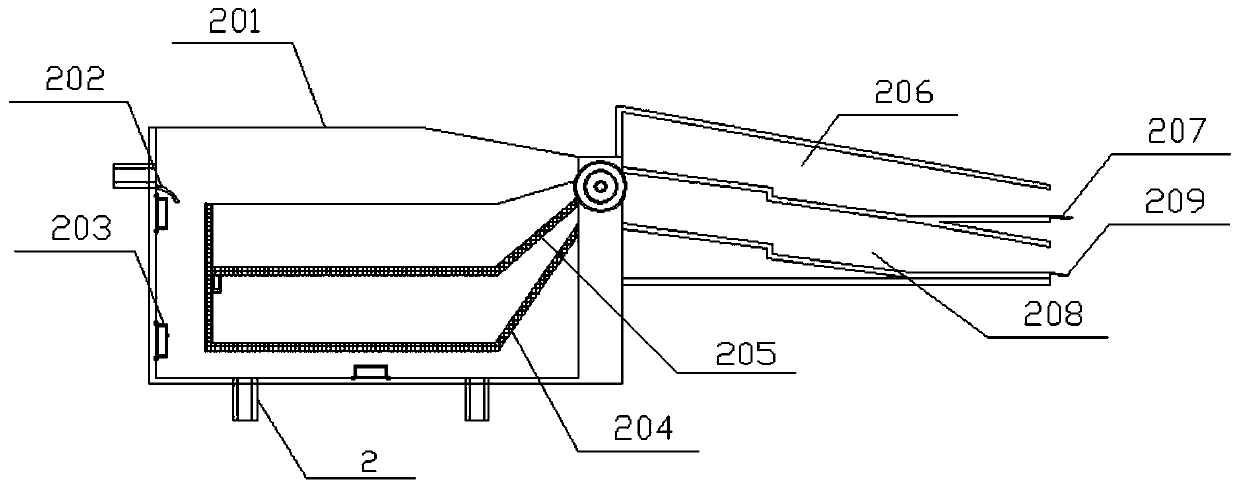

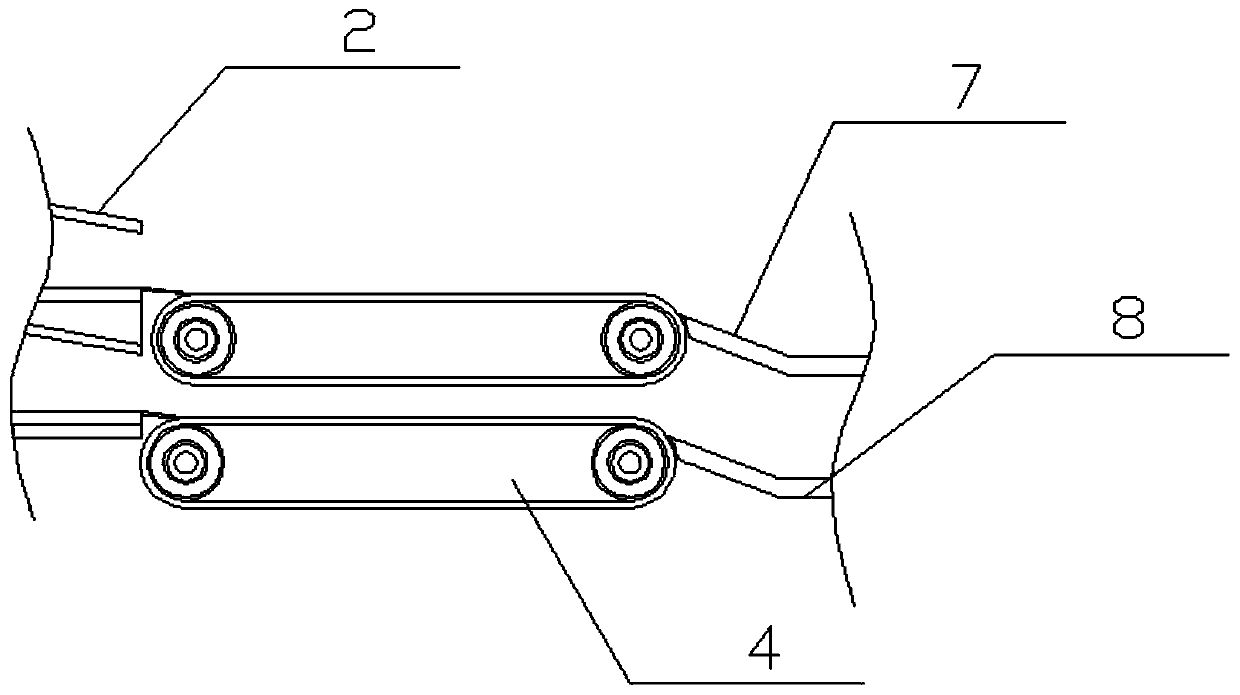

[0024] In this technical solution:

[0025] Contains substantially innovative components for the present invention.

[0026] Classification mechanism-2, crushing mechanism-6, separation mechanism-9, classification cabin-201, third deflector plate-202, ultrasonic generator-203, classification filter frame-204, classification filter plate-205, first split flow Cabin-206, first guide plate-207, second distribution cabin-208, second guide plate-209, slide rail cover-601, slide rail-602, first transmission rod-603, second transmission rod-604, The third transmission rod-605, the fourth transmission rod-606, the fifth transmission rod-607, the sixth transmission rod-608, the seventh transmission rod-609, the eighth transmission rod-6010, the ninth transmission rod-6011, Briquetting block-6012, outer shell-6013, separation cabin-901, first separation blade-902, second separation blade-903, lever-904, first bevel gear-905, second bevel gear-906, third The bevel gear-907 and the four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com