Microbial fermentation method for eliminating anti-nutritional factors in bean dreg feed

A technology of anti-nutritional factors and microbial fermentation, which is applied in animal feed, animal feed, food science, etc., can solve the problems of long fermentation cycle and incomplete removal of anti-nutritional factors, and achieves convenient operation, low cost and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

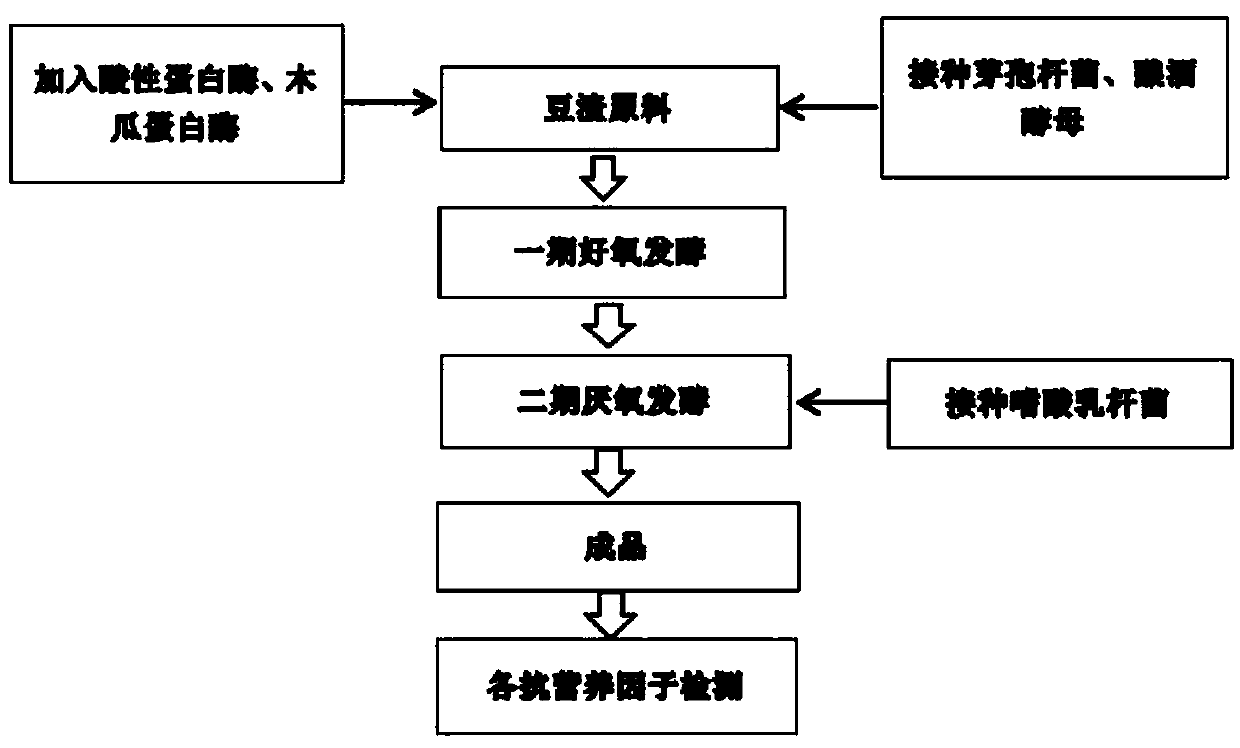

Method used

Image

Examples

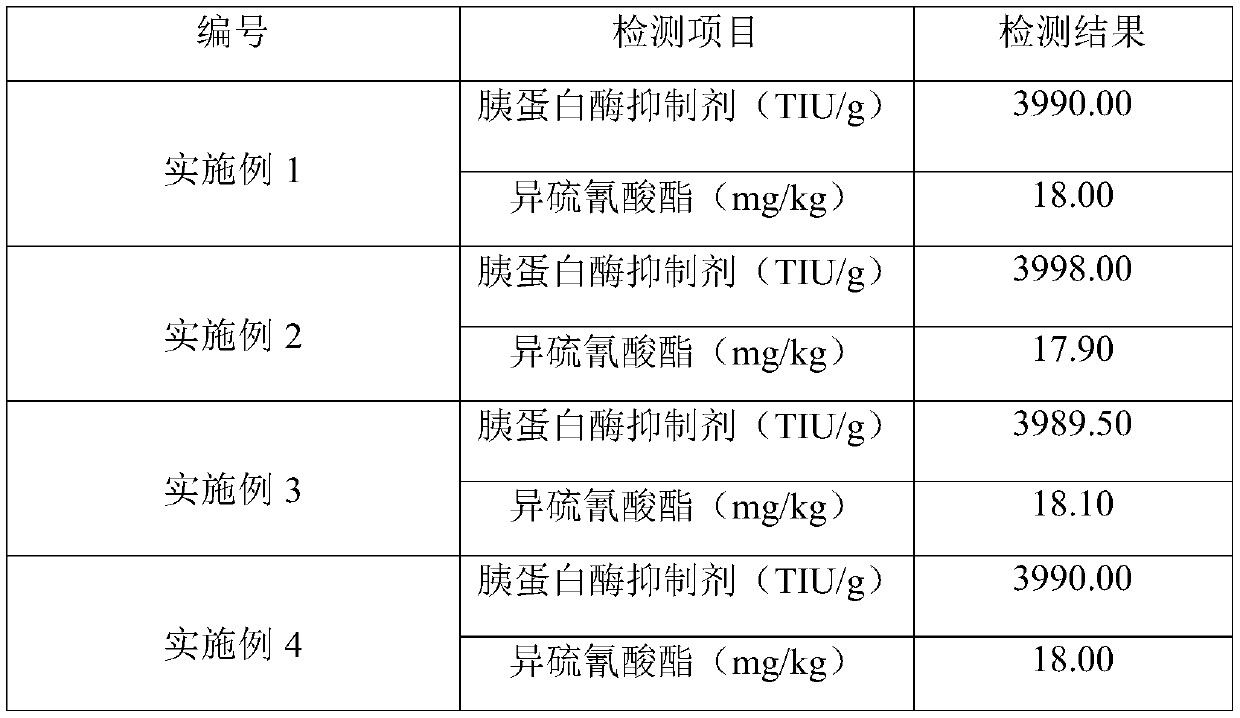

Embodiment 1

[0032] (1) Activation culture of Bacillus, Saccharomyces cerevisiae and Lactobacillus acidophilus:

[0033] A, first configure the substratum of bacillus, saccharomyces cerevisiae and lactobacillus acidophilus;

[0034] Bacillus slant and plate medium: yeast extract 5g, sodium chloride 10g, peptone 10g, agar 15g, glucose 5g, distilled water 1L, pH natural, sterilized at 110°C for 30min; the composition of the Bacillus liquid seed medium is the same as that of the slant medium , the difference is that no agar is added.

[0035] Yeast slant and plate medium: 15g peptone, 10g yeast extract powder, 10g glucose, 20g agar, 1000mL distilled water, natural pH, sterilized at 110°C for 20min. The composition of the yeast liquid seed medium is the same as that of the slant medium, the difference is that no agar is added.

[0036] Lactic acid bacteria slant and plate medium: yeast extract 5g, sodium chloride 10g, peptone 10g, agar 20g, glucose 15g, distilled water 1L, pH natural. Sterili...

Embodiment 2

[0045] (1) The activation culture of Bacillus subtilis, Saccharomyces cerevisiae and Lactobacillus acidophilus, concrete operation is the same as embodiment 1;

[0046] (2) Configure the first-stage aerobic fermentation medium, and the weight percentages of each component are respectively: 75% of bean dregs, 24.90% of bran, 0.05% of acid protease, and 0.05% of papain, and mix evenly to obtain the first-stage aerobic fermentation Culture medium;

[0047] (3) Inoculate the Bacillus subtilis fermented seed liquid and the Saccharomyces cerevisiae fermented seed liquid after step (1) activation culture to the aerobic fermentation medium, the inoculum size is 8%, the live bacteria of Bacillus subtilis and Saccharomyces cerevisiae The total is 3×10 9 cfu / mL, adjust the water content of the culture medium to 50%, the fermentation temperature is 30°C, and carry out aerobic fermentation for 36 hours. After the first-stage aerobic fermentation, the first-stage fermentation mixture is ob...

Embodiment 3

[0050] (1) The activation culture of Bacillus licheniformis, Saccharomyces cerevisiae and Lactobacillus acidophilus, concrete operation is with embodiment 1;

[0051] (2) Configure the first-stage aerobic fermentation medium, and the weight percentages of each component are respectively: 75% of bean dregs, 24.72% of rice bran, 0.08% of acid protease, and 0.2% of papain, and mix evenly to obtain the first-stage aerobic fermentation culture base;

[0052] (3) Inoculate the Bacillus licheniformis fermented seed liquid and the Saccharomyces cerevisiae fermented seed liquid after step (1) activation culture to the aerobic fermentation medium, the inoculum amount of the Bacillus licheniformis fermented seed liquid is 3%, and Saccharomyces cerevisiae fermented The inoculation amount of the seed liquid was 9%, and the total number of live bacteria of Bacillus licheniformis and Saccharomyces cerevisiae was 2×10 9 cfu / mL; adjust the water content of the medium to 50%, the fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com