Bottom support device special for automobile battery box

A technology for battery boxes and automobiles, which is applied to battery/fuel cell control devices, electric power devices, electric vehicles, etc., can solve the problems that the heat sink cannot achieve the heat dissipation effect, the long-term use of the battery box is unfavorable, and the installation stability of the battery box is poor. , to reduce the lateral vibration amplitude, improve the heat dissipation effect, and improve the shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

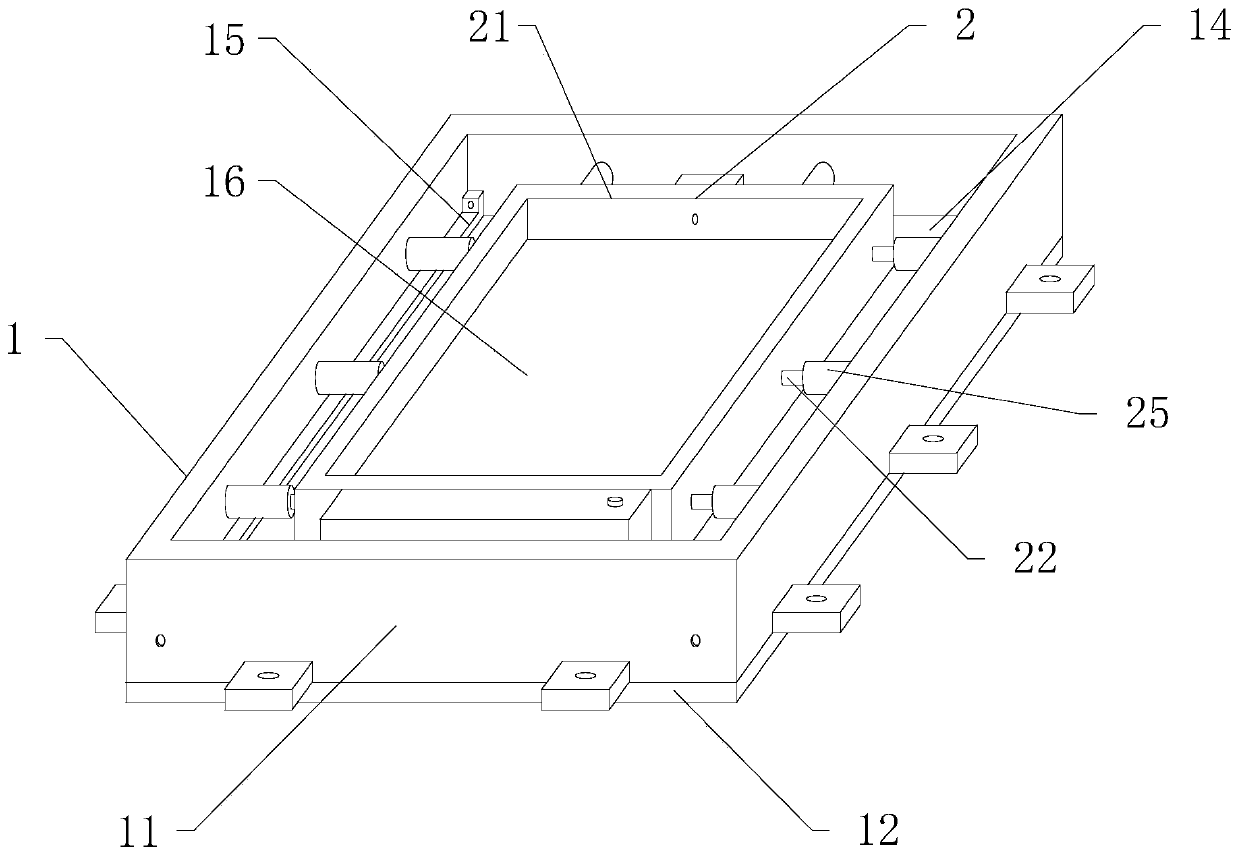

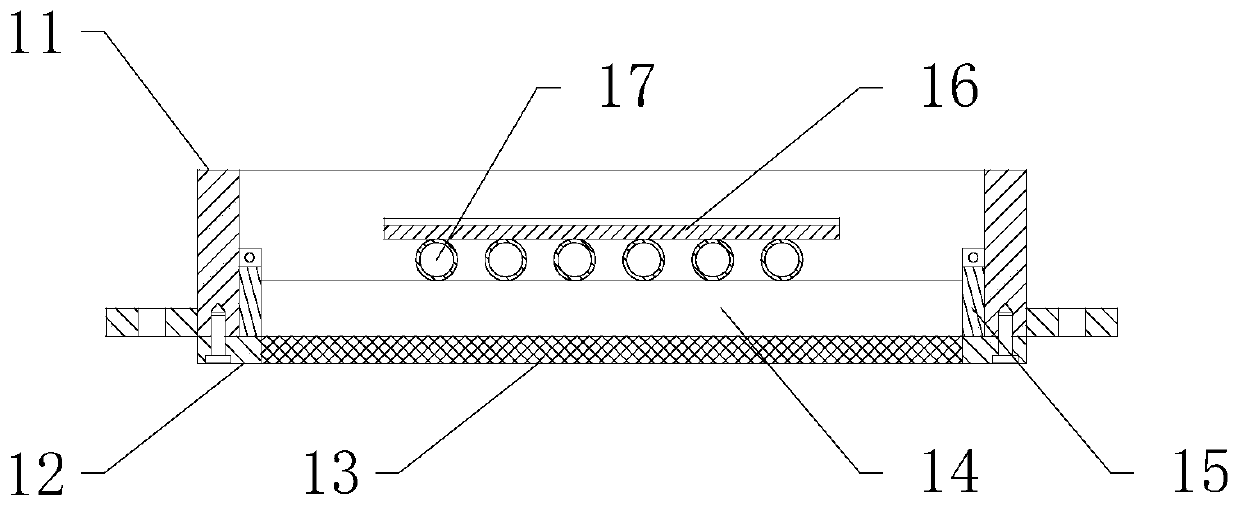

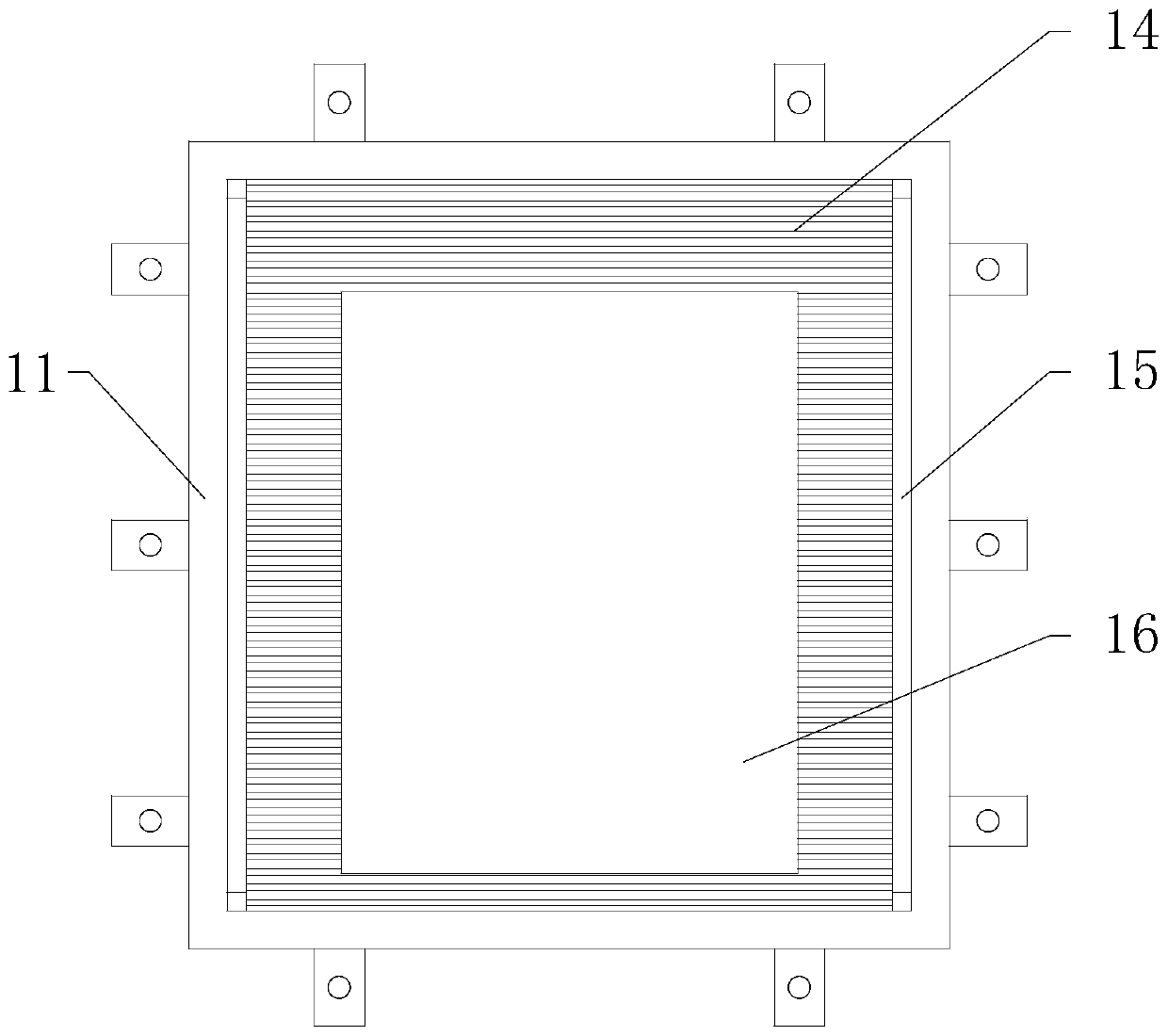

[0024] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

[0025] see Figure 1-Figure 8 , the present invention provides a technical solution: a special bottom support device for a car battery box, including a cooling mechanism 1 and a shock absorbing mechanism 2, the cooling mechanism 1 is equipped with a shock absorbing mechanism 2, and the cooling mechanism 1 includes a shell 11, a mounting frame 12, Dustproof net 13, cooling fins 14, comb teeth 15, cooling plate 16 and serpentine pipe 17, shock absorbing mechanism 2 includes inner shell 21, connecting rod 22, piston 23, shock absorbing spring 24 and silencer tube 25.

[0026] As an embodiment of the present invention: in the heat dissipation mechanism 1, the lower end of the housing 11 is fixed to the mounting frame 12 by bolts, the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com