Lithium triborate crystal surface antireflective microstructure and preparation method thereof

A lithium triborate, crystal surface technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., to achieve the effect of improving anti-laser damage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments.

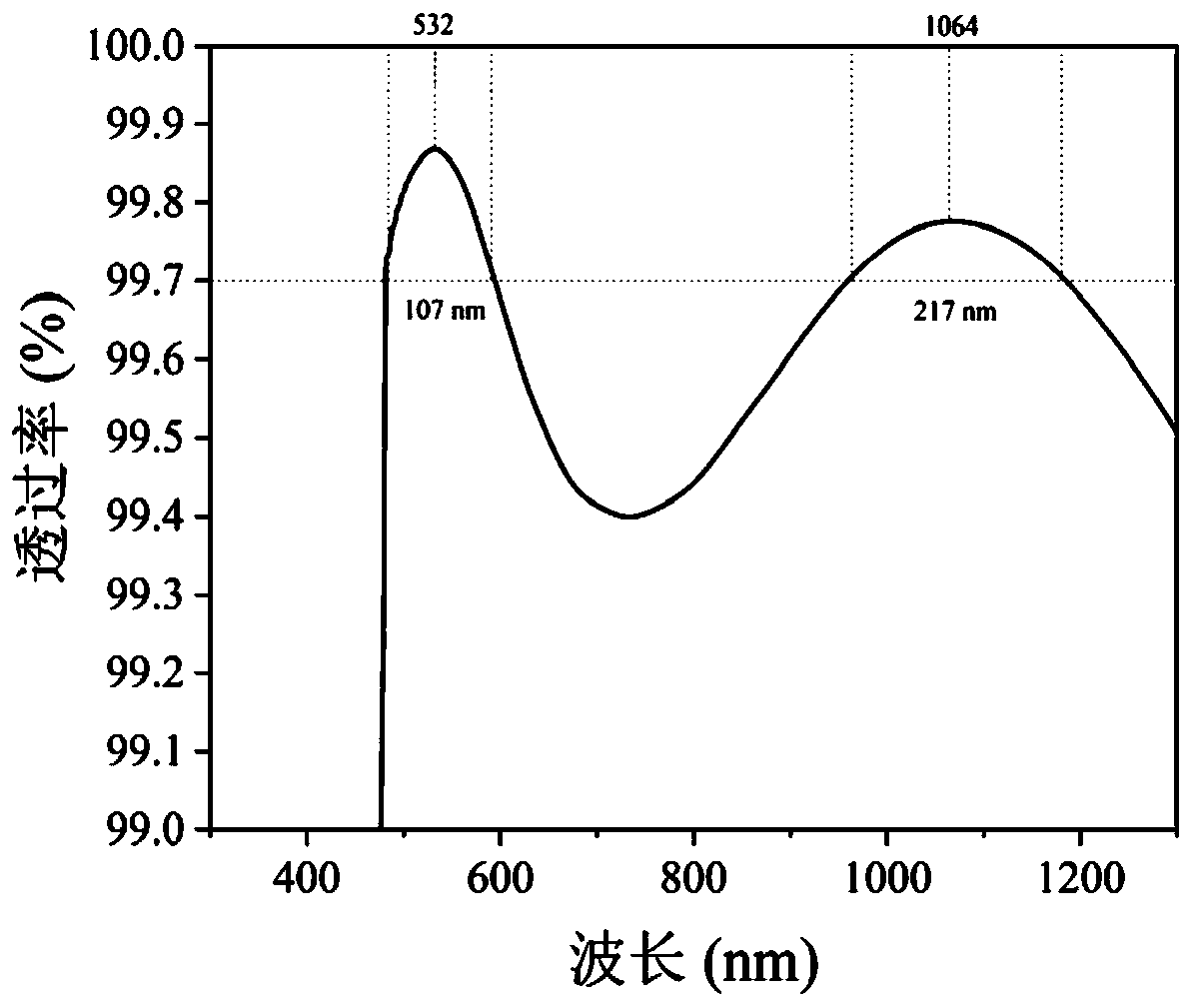

[0027] Since lithium triborate crystals are usually used for frequency conversion, the requirement is to have high transmittance to the input wavelength and output wavelength. The present invention uses the surface anti-reflection microstructure applied to two wavelengths of 1064nm and 532nm as an example. The microstructure is a periodic array structure directly prepared on the substrate, and the microstructure parameters include period, depth, duty cycle and the like.

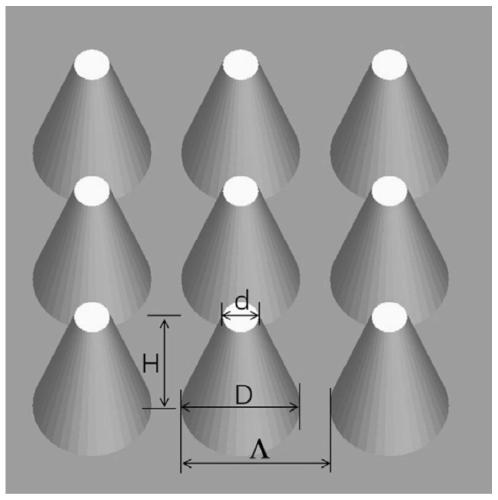

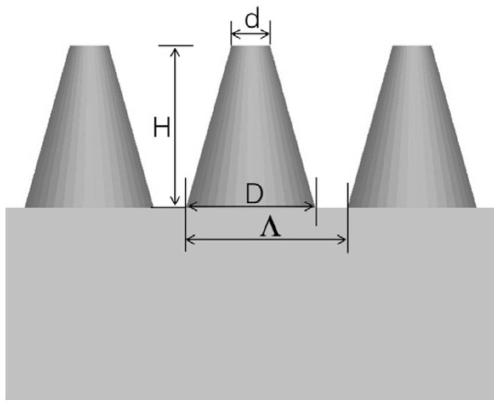

[0028] In this example, figure 1 It is a schematic diagram of the anti-reflection microstructure on the surface of lithium triborate crystal in the embodiment of the present invention. In the figure, Λ is the period of the microstructure, H is the depth of the microstructure, d is the diameter of the top of the microstructure, D is the diameter of the bottom of the microstructure, and the duty ratio of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com