Internal combustion engines with fuel injection nozzles having an additional mechanism for introducing a combustion-promoting medium into the combustion chamber

A medium and fuel technology, which is applied in the direction of bringing fuel into the engine, combustion engine, fuel injection device, etc. through high-pressure gas, which can solve the problem of combustion air entering the cylinder, and achieve the effect of improving combustion and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

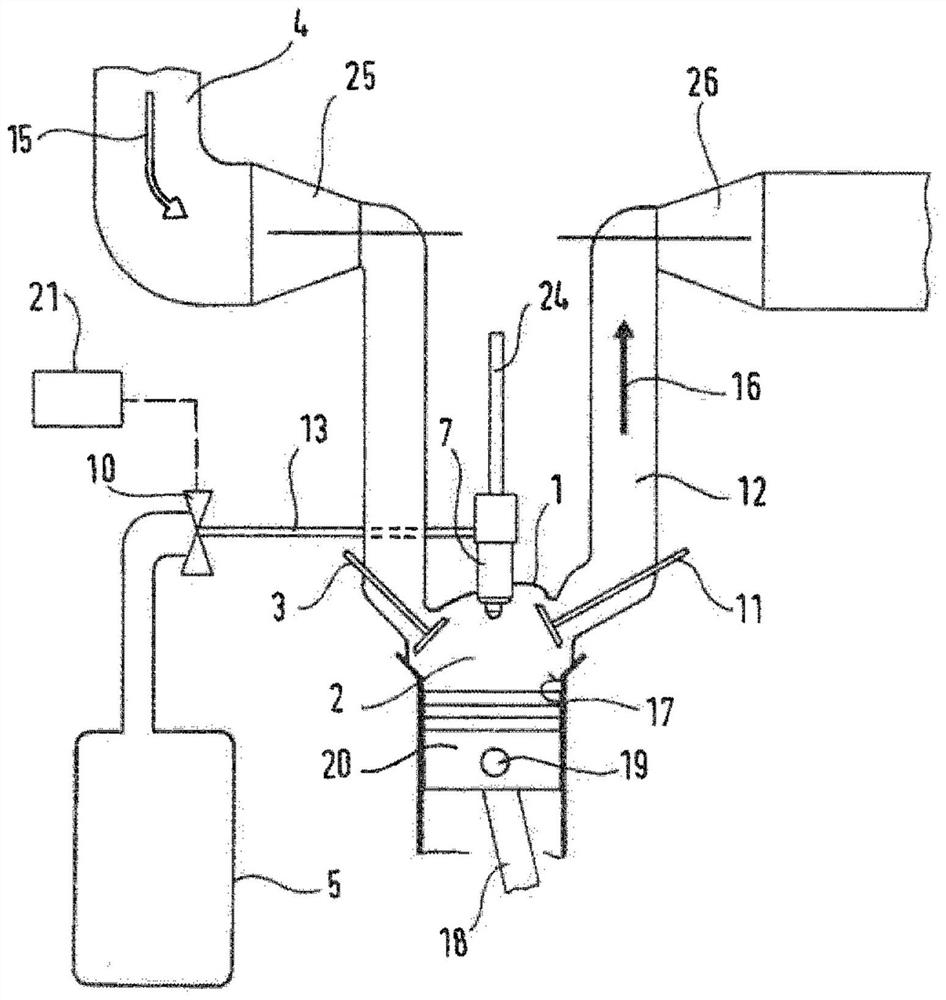

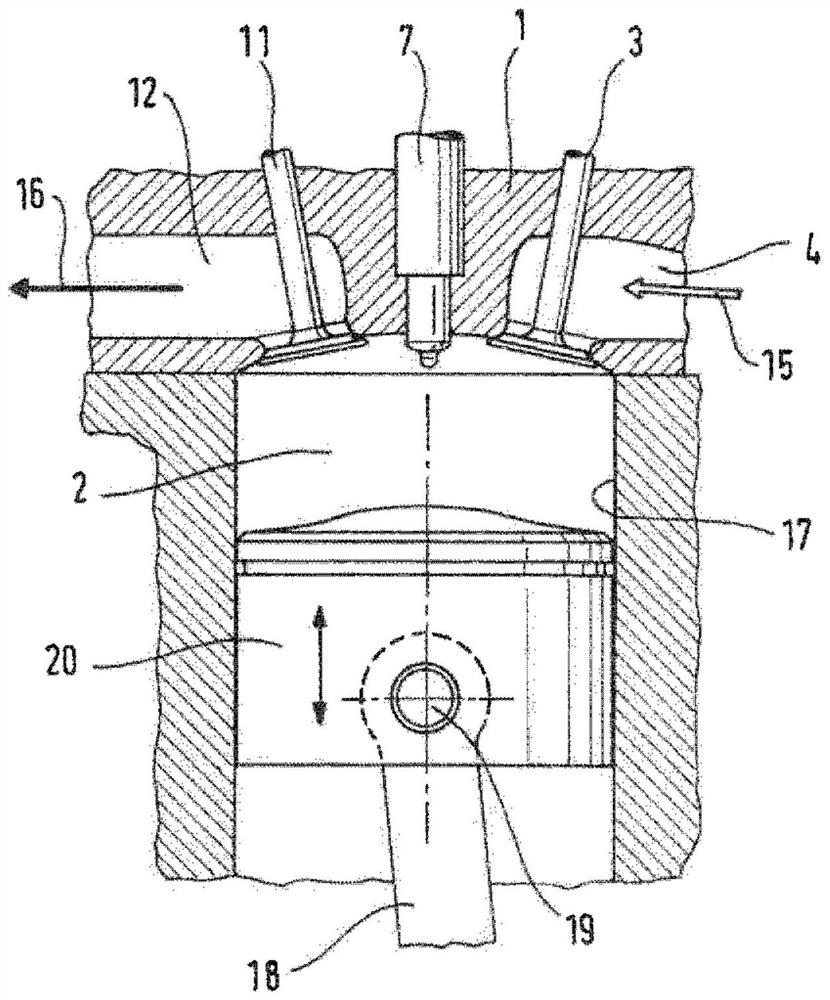

[0033] figure 1 Is a schematic view of a cylinder 2 of a reciprocating piston (engine) machine with an input valve 3 and an output valve 11 installed in the cylinder head 1. The input air 15 is conducted via the pressurized air line 4 or input line through a booster 25 for increasing the charging pressure and from there to the input valve 3 and, with the input valve 3 open, to the cylinder 2 middle. With the outlet valve 11 open, the combusted gases 16 after combustion flow through the outlet valve 11 into the exhaust gas line 12 and from there through the exhaust gas turbine 26 in which energy is extracted from the exhaust gas 16 for A pressure booster 25 arranged in the feed line 4 is driven.

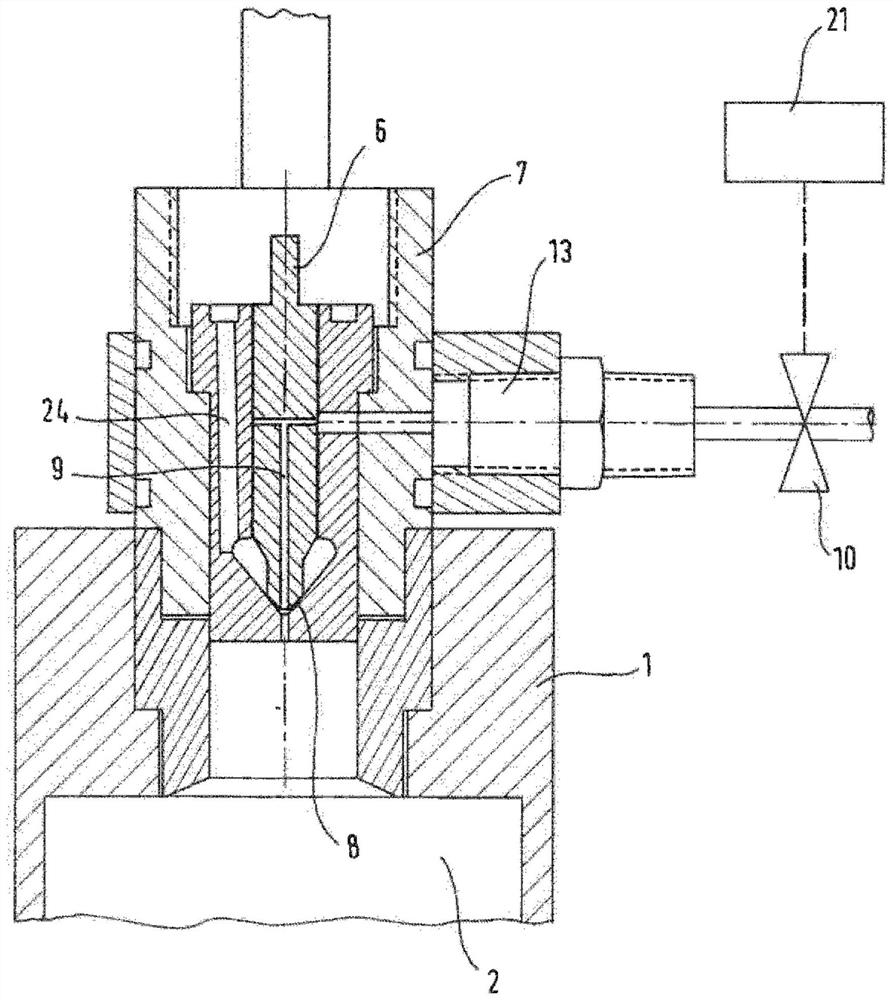

[0034] Also arranged in the cylinder head 1 is an injection nozzle 7 through which fuel is injected into the cylinder via a fuel line 24 for combustion of the fuel. Adjoining the injection nozzle 7 is a medium line 13 for a gaseous or liquid medium which is fed through the injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com