Mounting structure of rotor iron core and magnetic steel

A technology of mounting structure and rotor core, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electromechanical device, etc., can solve the problems of increasing the manufacturing cost of tooling, affecting the production efficiency of the workshop, and not improving the efficiency, so as to achieve saving Cost, facilitate assembly, and improve installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

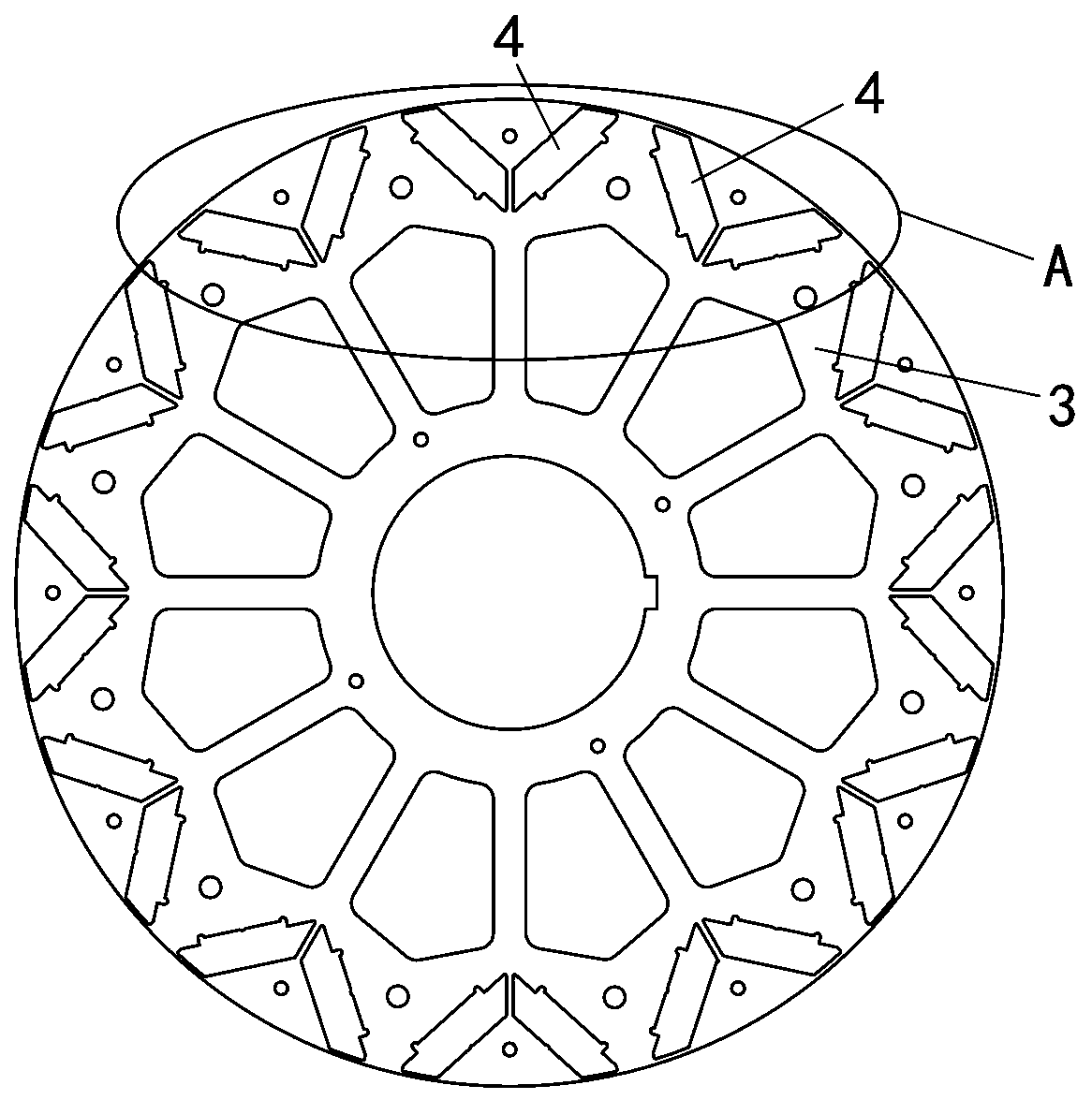

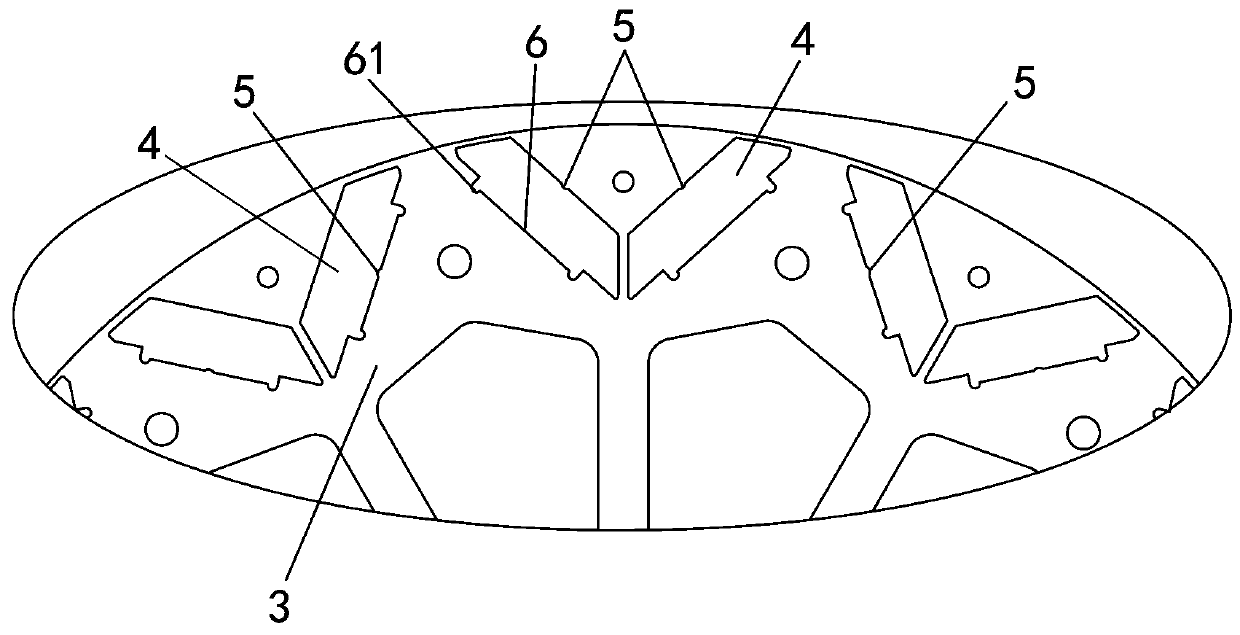

[0022] Embodiment one, see Figure 1 to Figure 5 As shown, a rotor core and magnetic steel installation structure includes a magnetic steel 2 and a rotor core 1 laminated by rotor punches 3, and a number of through holes 4 are evenly distributed on the rotor punches 3, through which The hole 4 is arranged in a ring on the outer peripheral edge of the rotor punching plate 3. The through hole 4 is similar to an isosceles trapezoidal shape, and two through holes 4 form a group. The through holes 4 in each group are symmetrically arranged on the left and right, and form a V shape. , the lower bottom of the through hole 4 is provided with an open slot 6, and the two ends of the bottom of the open slot 6 are respectively provided with a U-shaped slot 61. After the rotor core 1 is formed by stacking the rotor punches 3, the corresponding through hole 4 forms a magnetic steel installation hole. 20 , the magnet steel 2 is inserted into the magnet steel installation hole 20 .

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com