Waterproof anti-explosion cable sealing element

A technology of explosion-proof cables and seals, which is applied in the direction of electrical components, etc., can solve the problems of low fire and explosion-proof performance, short service life of materials, and short circuit of circuits, so as to improve poor sealing, improve radiation resistance, and avoid safety hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

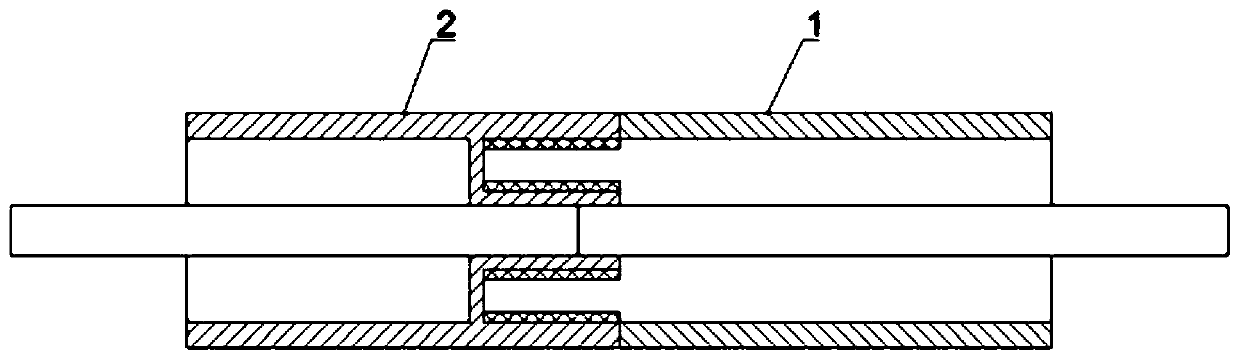

[0068] Such as figure 1 The waterproof and explosion-proof cable seal shown is characterized in that it includes: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 3 overlaps the axis of the second sealing tube 2; the first sealing tube 2 The sealing tube 1 is locked in contact with the second sealing tube 2; the first sealing tube 1 is composed of a first front end and a first rear end; the second sealing tube 2 is composed of a second front end and a second rear end group; The second front end is provided with a protruding part, and a limiting cavity is formed between the protruding part and the second front end, and the limiting cavity extends along the axial direction of the second connecting pipe; the limiting cavity A sealant is provided inside; the first rear end is plugged into the limiting cavity; the first rear end is connected with the second front end by an interference fit through the sealant;

[0069] The preparation process ...

Embodiment 2

[0114] Such as figure 1 The waterproof and explosion-proof cable seal shown is characterized in that it includes: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 3 overlaps the axis of the second sealing tube 2; the first sealing tube 2 The sealing tube 1 is locked in contact with the second sealing tube 2; the first sealing tube 1 is composed of a first front end and a first rear end; the second sealing tube 2 is composed of a second front end and a second rear end group; The second front end is provided with a protruding part, and a limiting cavity is formed between the protruding part and the second front end, and the limiting cavity extends along the axial direction of the second connecting pipe; the limiting cavity A sealant is provided inside; the first rear end is plugged into the limiting cavity; the first rear end is connected with the second front end by an interference fit through the sealant;

[0115] The preparation process ...

Embodiment 3

[0160] Such as figure 1 The waterproof and explosion-proof cable seal shown is characterized in that it includes: a first sealing tube 1 and a second sealing tube 2; the axis of the first sealing tube 3 overlaps the axis of the second sealing tube 2; the first sealing tube 2 The sealing tube 1 is locked in contact with the second sealing tube 2; the first sealing tube 1 is composed of a first front end and a first rear end; the second sealing tube 2 is composed of a second front end and a second rear end group; The second front end is provided with a protruding part, and a limiting cavity is formed between the protruding part and the second front end, and the limiting cavity extends along the axial direction of the second connecting pipe; the limiting cavity A sealant is provided inside; the first rear end is plugged into the limiting cavity; the first rear end is connected with the second front end by an interference fit through the sealant;

[0161] The preparation process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com