Air tightness detection device used for water pump manufacturing

A technology of air tightness detection and water pump, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems of large labor force, complicated connection process, and low production efficiency, so as to reduce labor force, simple operation, and simplified The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

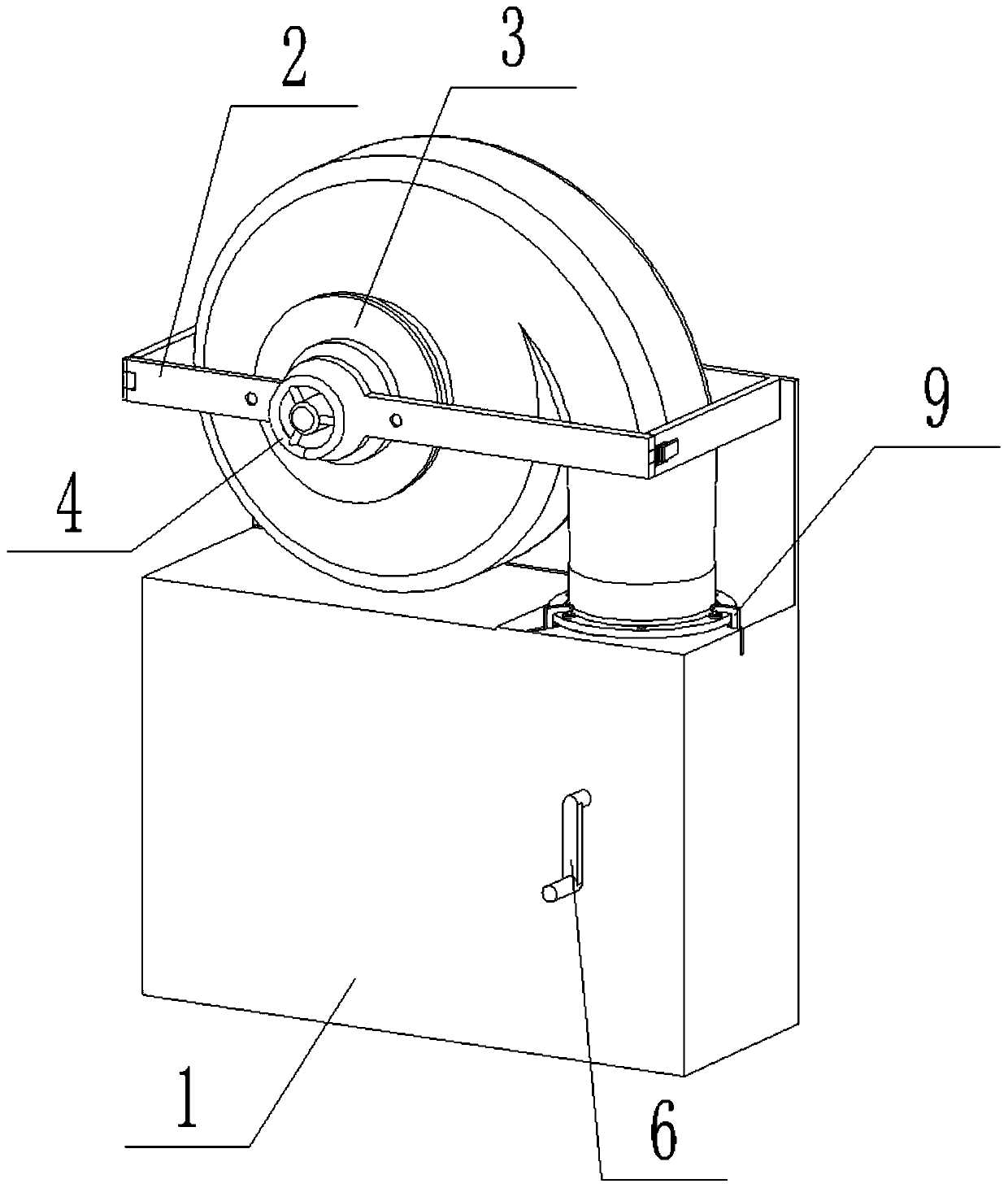

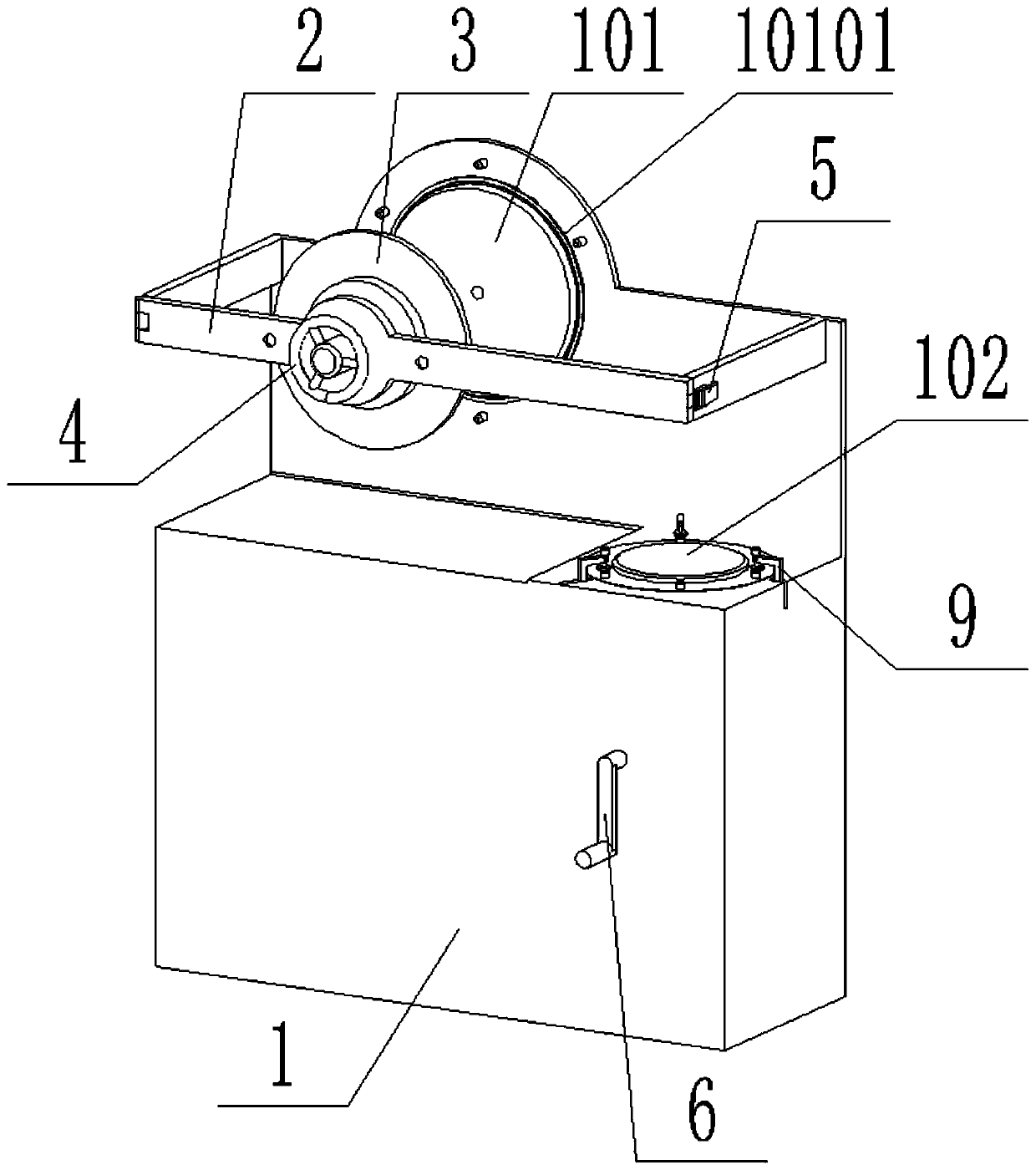

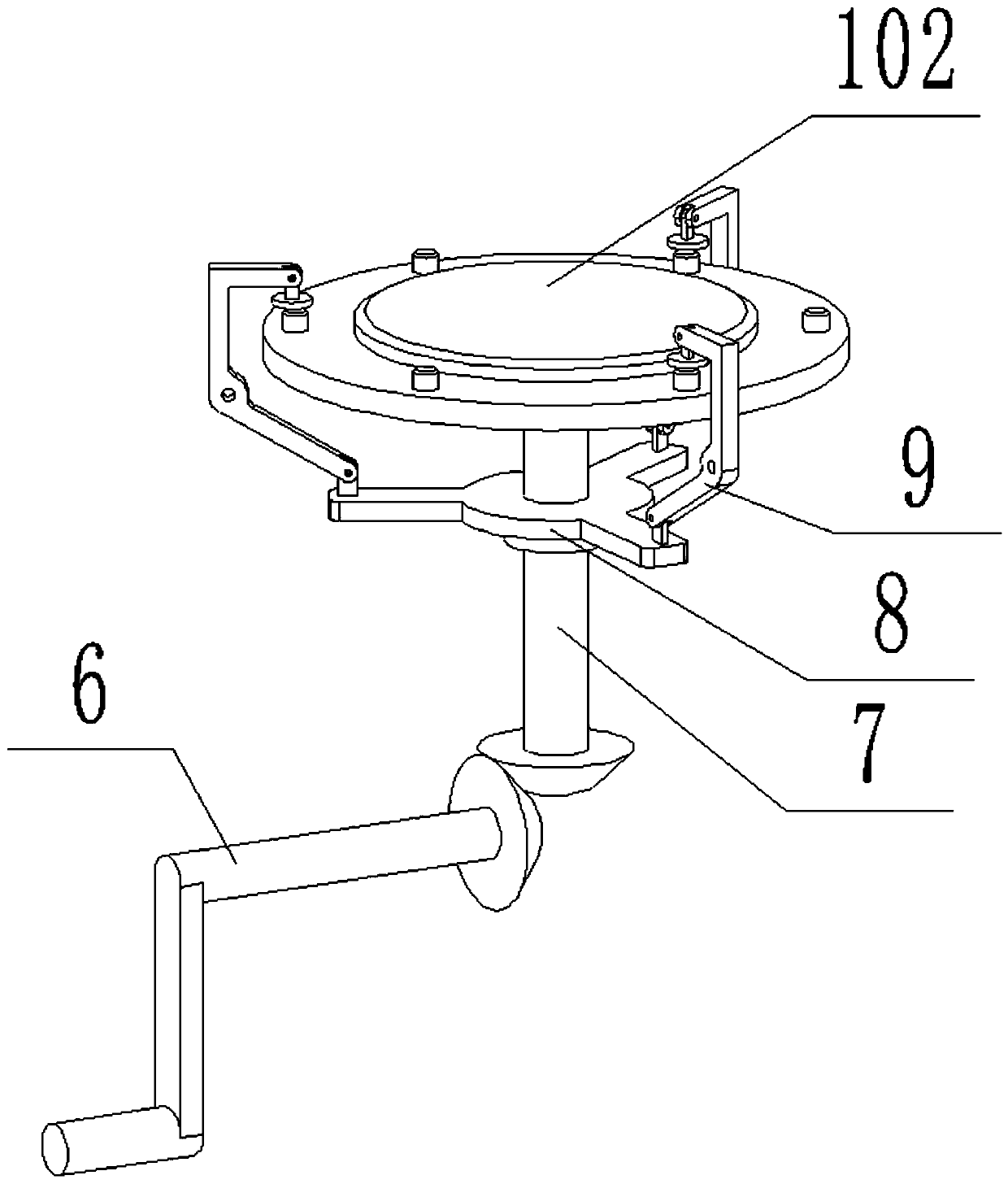

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The present invention provides an air tightness detection device for water pump manufacturing, including: a machine 1, a rear end cover 101, a sealing gasket 10101, an air nozzle 10102, a positioning pin 10103, a lower end cover 102, a connecting plate 2, a front end cover 3, Sliding guide rod 301, handle 4, hasp lock 5, handle 6, lifting screw rod 7, lifting connecting rod 8 and compression rod 9; a group of connecting plates 2 are hinged on the left side of the front surface of machine table 1; A set of handles 4 is threaded on the middle part; a set of front cover 3 is slidably connected to the rear end of the connecting plate 2; the front cover 3 is slidably connected to the handle 4; the right side of the connecting plate 2 is fixedly connected to the machine 1 through a hasp lock 5 A group of rear end covers 101 are fixedly connected to the rear end surface of the machine table 1; a group of handles 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com