Warmer

A technology for heaters and heat sinks, applied in the field of heaters, which can solve the problems of easy misuse, shrinkage, and exacerbation of heating problems of end heat sinks, etc., to achieve the effect of ensuring user experience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

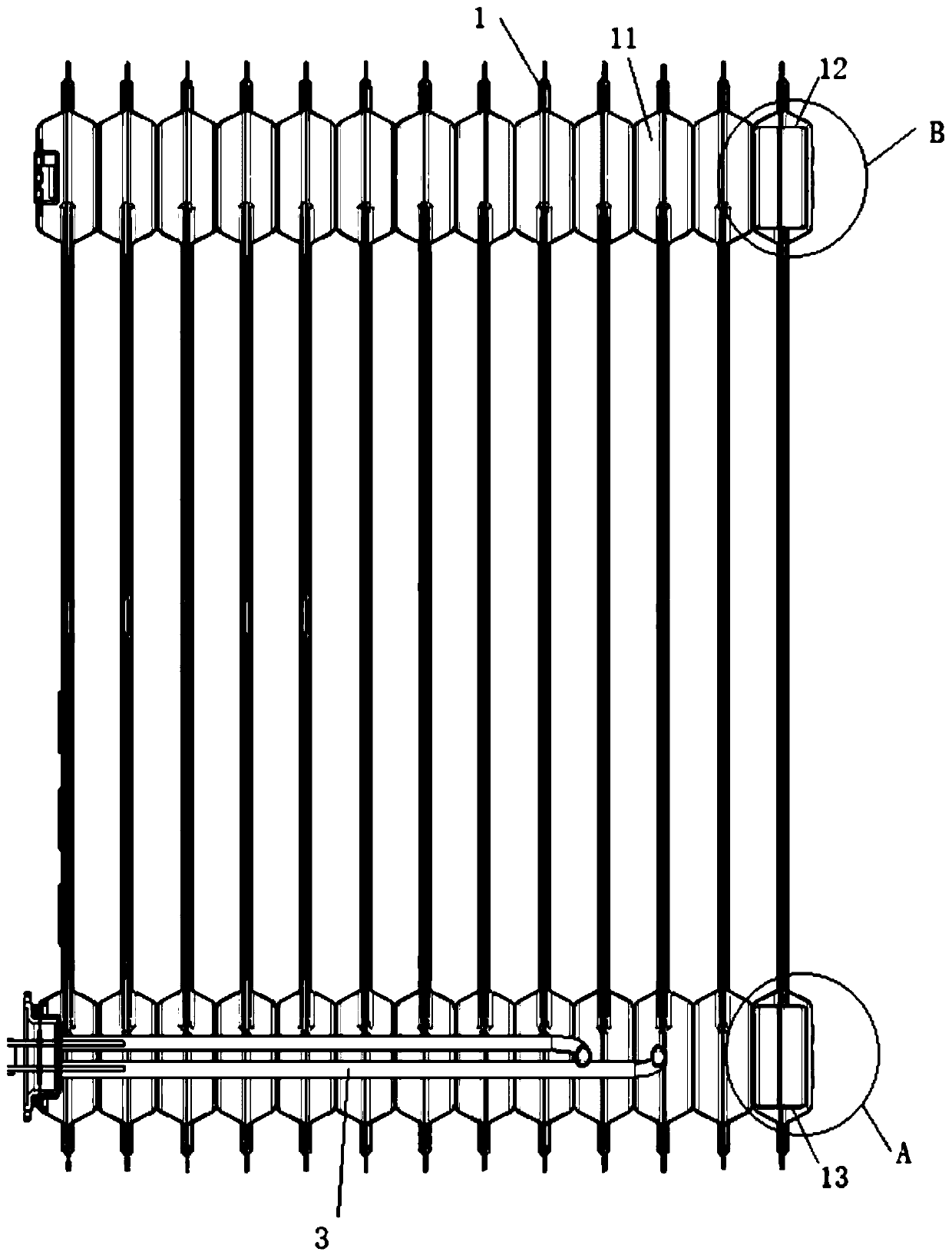

[0030] heater according to the present invention, such as image 3 As shown, it includes a heating device 3 and a plurality of heat sinks 1, each of which is provided with at least two oil storage chambers 11, and the oil storage chambers 11 in the same heat sink communicate with each other, so The plurality of cooling fins 1 are sequentially connected through the oil storage chamber 11 to form a circulation channel, the connection between the circulation channel and the oil storage chamber 11 is the circulation channel opening 14, and the heating device 3 is arranged in the circulation channel. In this embodiment, the first heat sink 1 or the last heat sink 1, or the first heat sink 1 and the last heat sink 1 of the plurality of heat sinks 1 connected in sequence are defined as end heat sinks.

[0031] Such as image 3 As shown, in the present invention, a flow limiting device 12 is provided in at least one oil storage cavity 11 of the end heat sink, and a flow blocking devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com