An inertial capacity device with adjustable inertial capacity

A capacity and inertial capacity technology, applied in the field of inertial capacity devices, can solve the problems of moment of inertia change, inaccurate inertial capacity, large wear, etc., and achieve the effect of small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

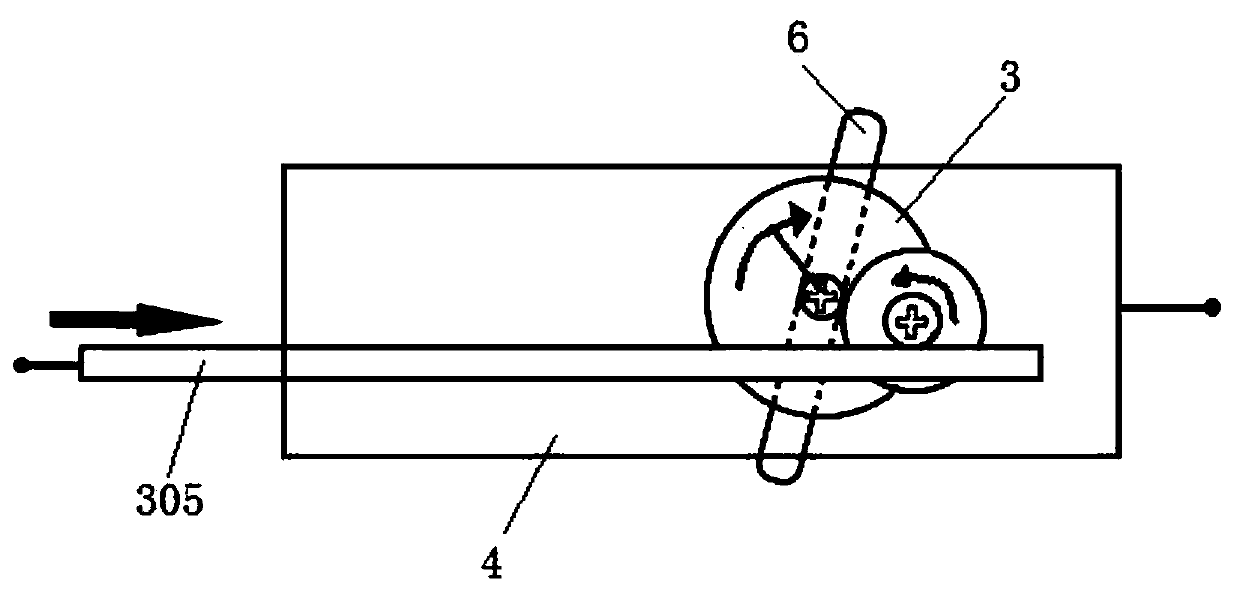

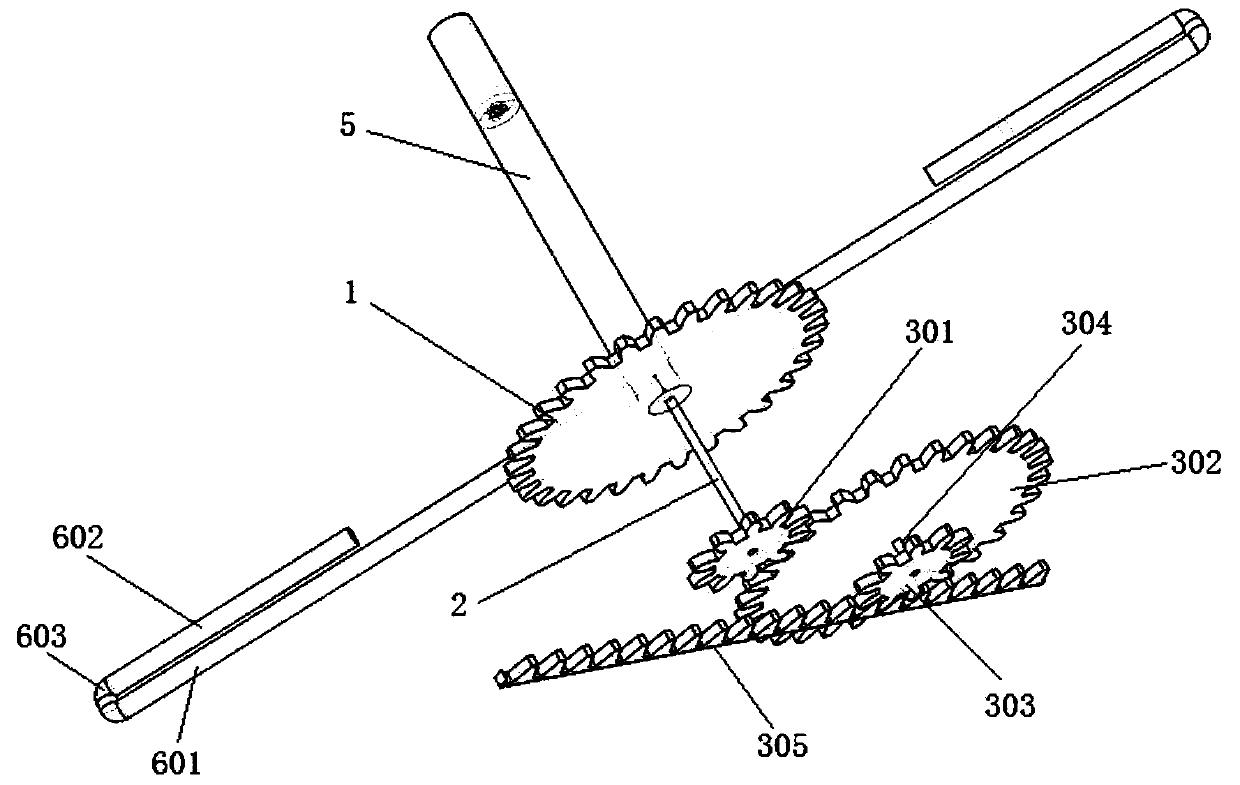

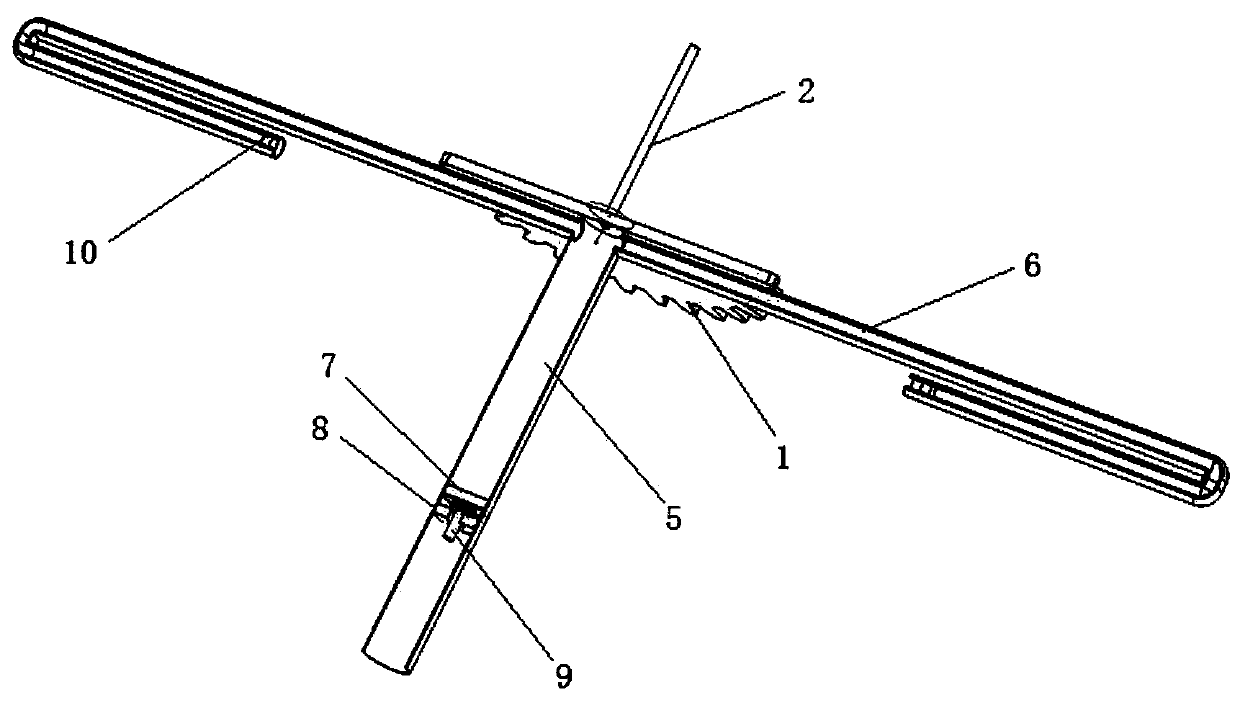

[0019] Such as figure 1 , The rack 305 is placed in the guide rail of the box body 4 and can move in translation. The rack 305 and the box body 4 are two relatively free ends of the inertial capacity. Such as Figure 2~4 , the rack 305 meshes with the second pinion 303, the bull gear 302 is connected with the second pinion 303 through the second shaft 304, the first pinion 301 meshes with the bull gear 302, and the first pinion 301 passes through the first shaft 2 It is connected with the flywheel 1, and the first rotating shaft 2 is connected with the box body 4 through bearings. Different T-shaped liquid storage pipes are installed on the flywheel 1, the axial direction is called the main pipe 5, and the radial direction is called the side pipe 6. The liquid storage pipe is sealed and filled with liquid, and flows only when the push-pull rod 9 is displaced. The side pipe 6 is a U-shaped pipe with two opposite openings. The U-shaped pipe includes a long pipe 601 , a short p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com