Slow-release agarwood microcapsule, and preparation method and application thereof

A technology of slow-release microcapsules and agarwood, applied in the field of washing, can solve the problem of insufficient long-lasting fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

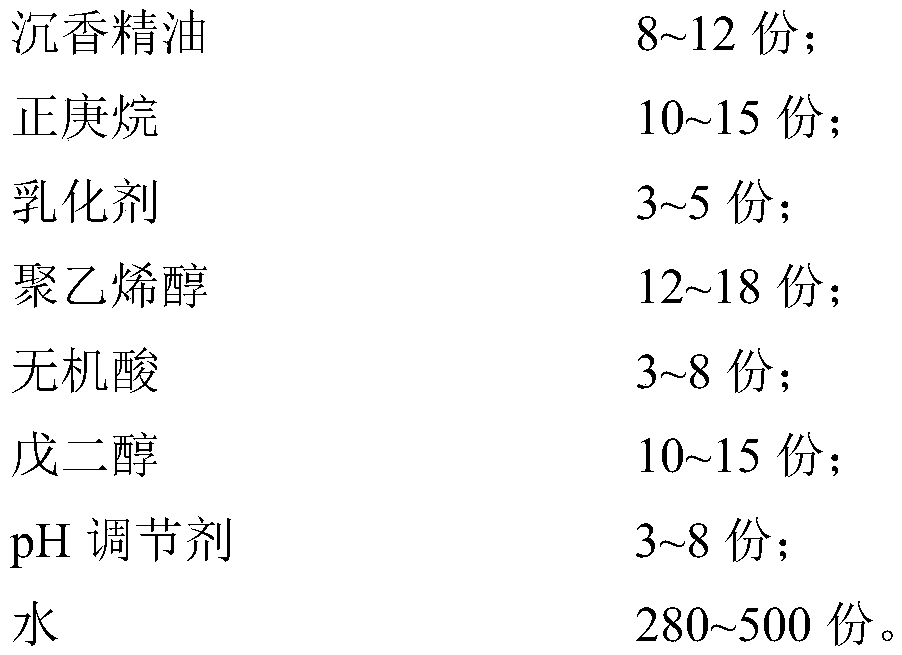

[0032] A kind of agarwood slow-release microcapsules, obtained by the following preparation method:

[0033] Emulsification reaction: Add 10g of agarwood essential oil into a flask containing 12.5g of n-heptane, then add 3g of emulsifier Span 80, and mechanically stir in a water bath at 25°C for 3 hours;

[0034] Dissolving polyvinyl alcohol: Weigh 15g of polyvinyl alcohol solid, add it to a beaker, add water, heat to dissolve under stirring conditions, and prepare a polyvinyl alcohol solution with a mass fraction of 3.8%. The polyvinyl alcohol solution is a transparent liquid;

[0035] Polymerization reaction: at 48°C, add the polyvinyl alcohol solution into the flask after the emulsification reaction, stir for 15 minutes, then slowly add 9ml of 36% hydrochloric acid solution and 5ml of pentanediol dropwise to make the solution acidic, Stop adding hydrochloric acid, continue to slowly add 10ml of pentanediol dropwise, after reacting for 30 minutes, stop heating, and then adju...

Embodiment 2

[0037] A kind of agarwood slow-release microcapsules, obtained by the following preparation method:

[0038] Emulsification reaction: Add 8g of agarwood essential oil into a flask containing 10g of n-heptane, then add 3g of emulsifier Span 80, and mechanically stir in a water bath at 25°C for 3 hours;

[0039] Dissolving polyvinyl alcohol: Weigh 12g of polyvinyl alcohol solid, add it to a beaker, add water, heat to dissolve under stirring conditions, and make a polyvinyl alcohol solution with a mass fraction of 3.6%. The polyvinyl alcohol solution is a transparent liquid;

[0040] Polymerization reaction: at 48°C, add the polyvinyl alcohol solution into the flask after the emulsification reaction, stir for 15 minutes, then slowly add 9ml of 36% hydrochloric acid solution and 3ml of pentanediol dropwise to make the solution acidic, Stop adding hydrochloric acid, continue to slowly add 10ml of pentanediol dropwise, after reacting for 25 minutes, stop heating, and then adjust the...

Embodiment 3

[0042] A kind of agarwood slow-release microcapsules, obtained by the following preparation method:

[0043] Emulsification reaction: Add 12g of agarwood essential oil into a flask containing 15g of n-heptane, then add 5g of emulsifier Span 80, and mechanically stir in a water bath at 25°C for 3 hours;

[0044] Dissolving polyvinyl alcohol: Weigh 18g of polyvinyl alcohol solid, add it to a beaker, add water, heat to dissolve under stirring conditions, and prepare a polyvinyl alcohol solution with a mass fraction of 4.0%. The polyvinyl alcohol solution is a transparent liquid;

[0045] Polymerization reaction: at 48°C, add the polyvinyl alcohol solution into the flask after the emulsification reaction, stir for 15 minutes, then slowly add 9ml of 36% hydrochloric acid solution and 5ml of pentanediol dropwise to make the solution acidic, Stop adding hydrochloric acid, continue to slowly add 10ml of pentanediol dropwise, after reacting for 35 minutes, stop heating, and then adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com