A ribbon automatic processing device

An automatic processing and webbing technology, applied in the field of textile webbing, can solve problems such as webbing cutting, and achieve the effect of ensuring a fixed length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

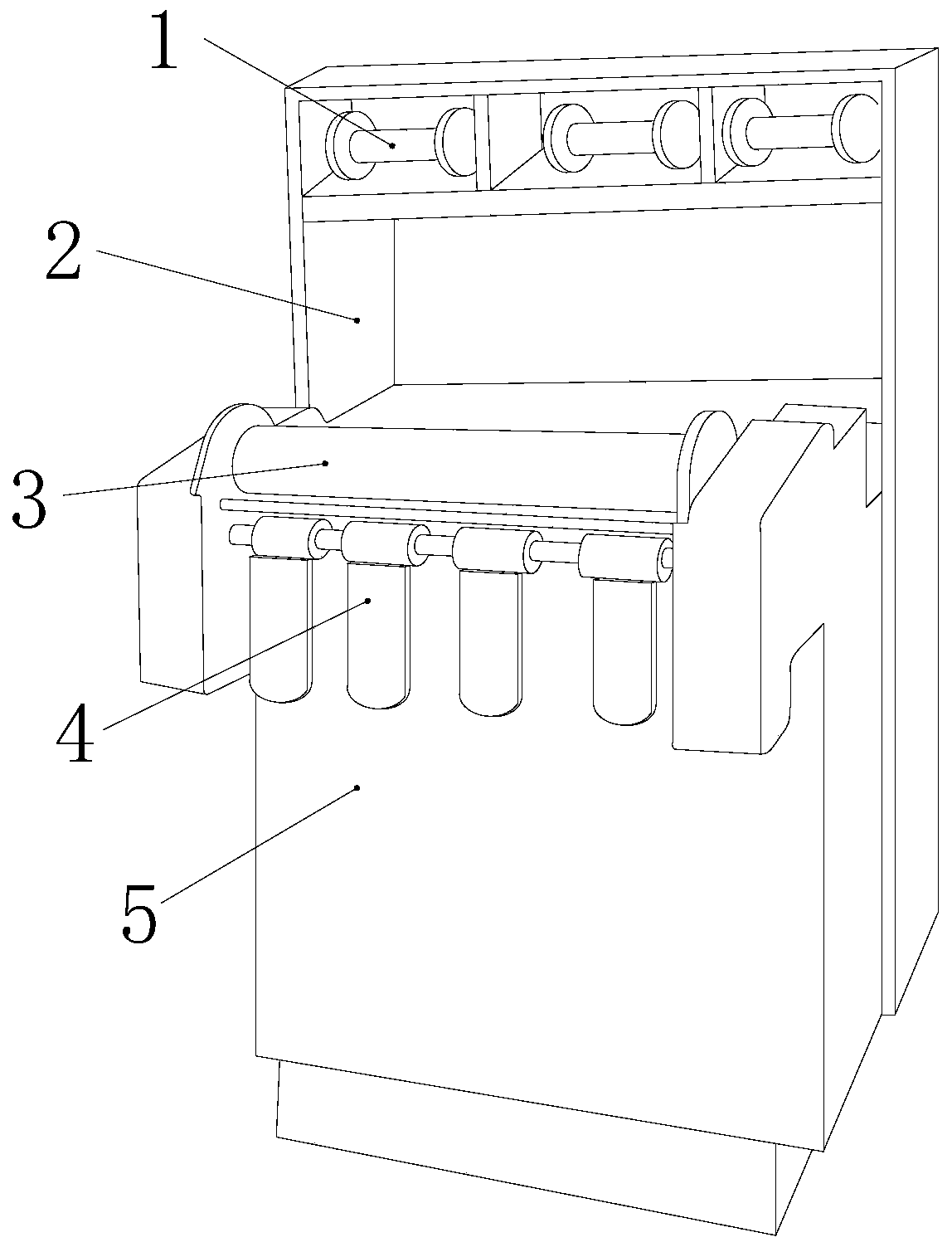

[0025] see Figure 1-Figure 6 , the present invention provides an automatic ribbon processing device, the structure of which includes a placing frame 1, a workbench 2, an integrated device for cutting and pulling materials 3, a guide plate 4, and a base 5, the placing frame 1 is set above the workbench 2, and the The workbench 2 and the base 5 are fixedly welded, the base 5 is connected to the placement frame 1 through the workbench 2, the cutting and drawing integrated device 3 is installed on the workbench 2, and the guide plate 4 and the workbench 2 are connected to each other. Vertically, the guide plate 4 is connected with the base 5;

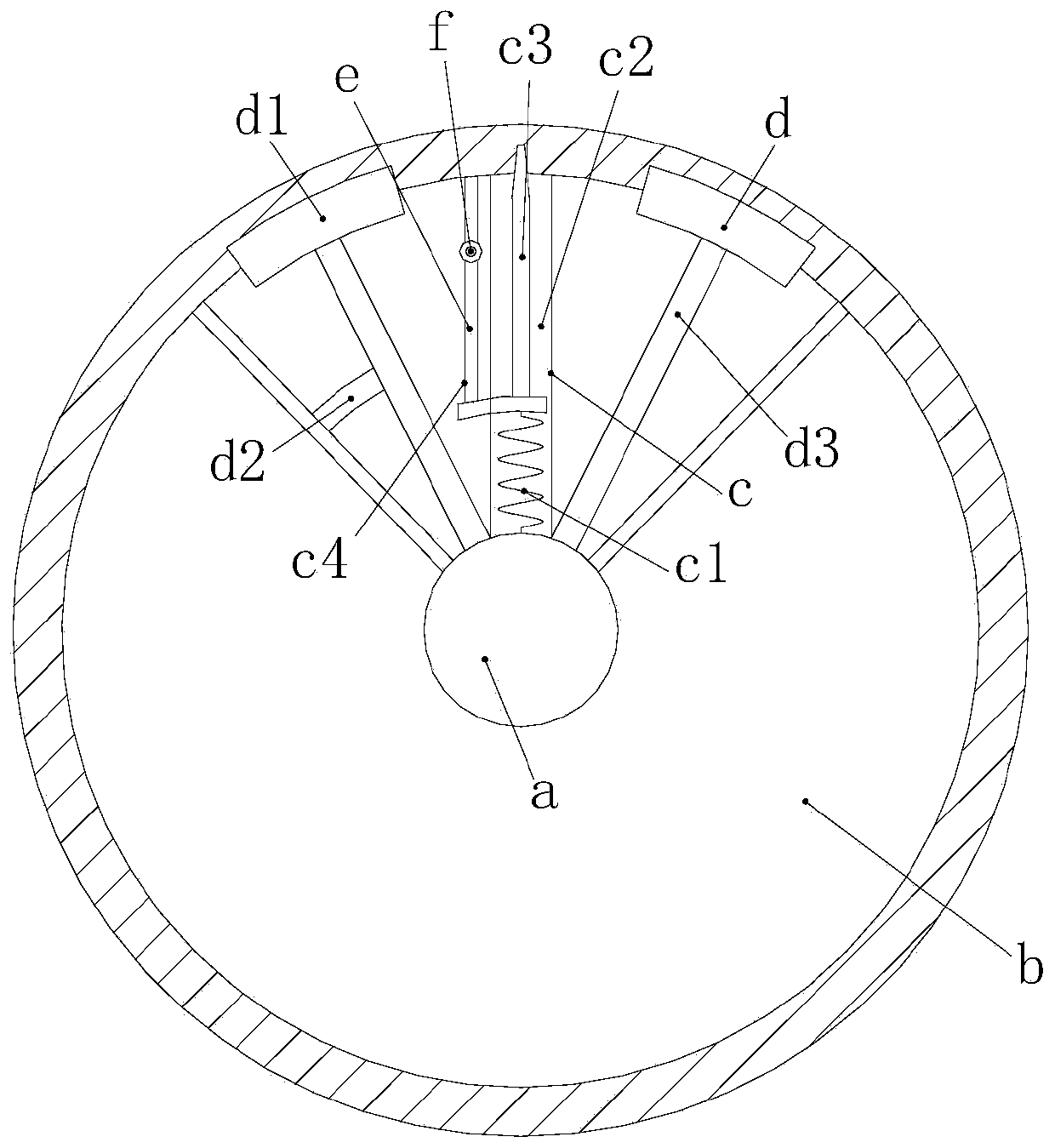

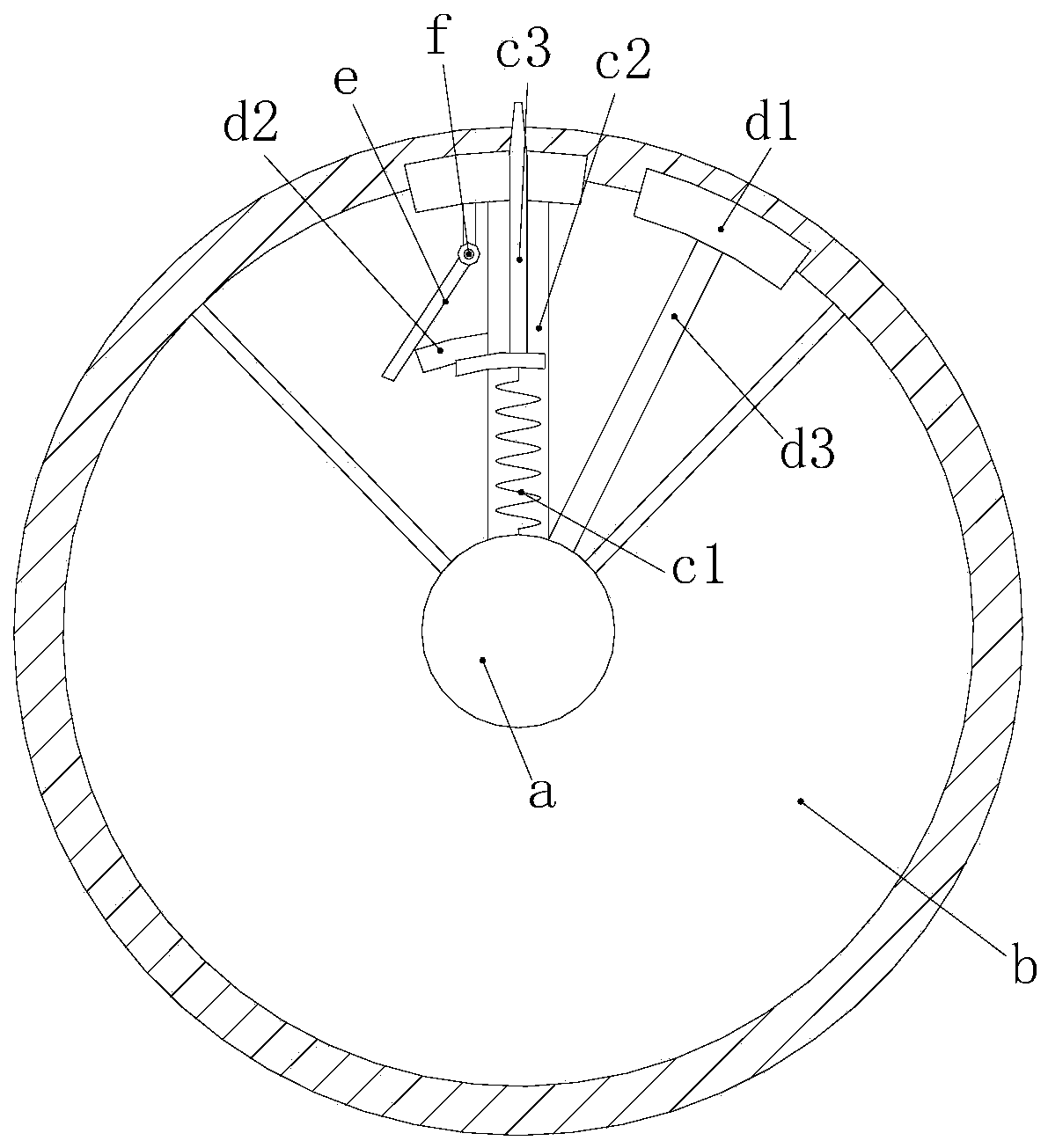

[0026] The cutting and pulling material integrated device 3 is composed of a central axis a, a transmission roller b, a cutting mechanism c, and a material pulling mechanism d. The central axis a is set at the center of the transmission roller b, and the transmission roller b and the central axis a are mechanically transmitted Cooperate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com