Temperature-compensating and temperature-adjusting annealing furnace system

An annealing furnace and temperature adjustment technology, which is applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of low automation, sealing problems, and high manufacturing difficulty, and achieve high safety, good sealing, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

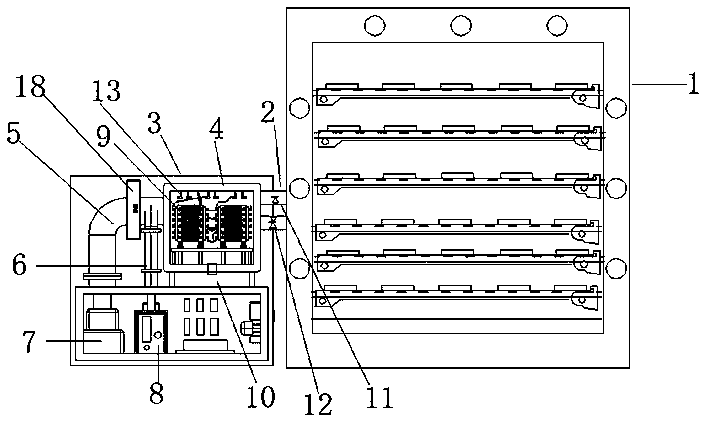

[0035] Embodiment 1: A temperature-supplementing and temperature-regulating annealing furnace system, including a furnace main body 1 and a complementary temperature regulator 3. The furnace main body 1 here mainly refers to a vacuum annealing furnace under the prior art, and what is required is that it is equipped with a prior art After the basic or integrated device is required, it is also necessary to set an interface of a compensation vent pipe 2 outward in its internal warehouse, and then set a compensation vent pipe 2 through this interface, and then the complementary thermostat 3 passes through the compensation The ventilation pipe 2 is connected with the furnace main body 1;

[0036] Wherein: the complementary thermostat 3 includes a thermostat chamber 4, a condensation vacuum tube 5, a mechanical vacuum tube 6, a condensation vacuum pump 7, a mechanical vacuum pump 8, 6 main components, and as figure 1 shown;

[0037] continue as figure 1 As shown, the temperature a...

Embodiment approach

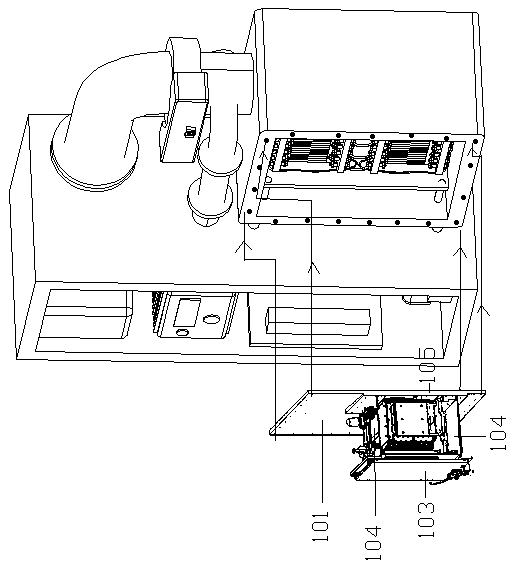

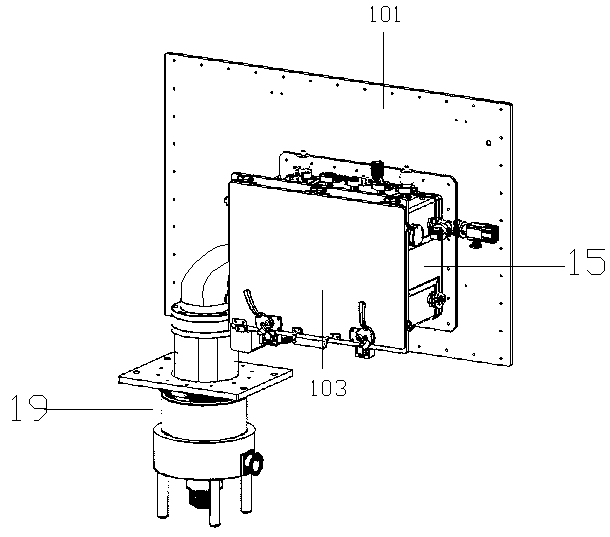

[0044] Implementation method: such as figure 1 As shown, after welding the additional warehouse cover plate 201, and assembling the main moving rail 202, the macro moving rail 215 is arranged between the outside of the cabin door 17 and the inside of the main moving rail 202, and then on the two sides The upper cover horizontal frame 203 is suspended horizontally between the two, and the cover horizontal frame 203 will combine the upper groove and protect the internal components, and the micro-motor carriage 210 at the bottom will correspond to the main moving rail 202 and the macro movement respectively. Rail 215, let the two move in linkage and move down to cover the hatch 17 for sealing. The correct moving distance of the sealing will be controlled by the grating sensor, and then the airtightness test after sealing will be carried out by itself. The airtightness sensor 1. The temperature sensor will monitor the data for feedback. If there is fluctuation or exceeds the stand...

Embodiment 2

[0054] Such as figure 1 As shown, a temperature-supplementing and temperature-regulating annealing furnace system includes a furnace body 1, a compensation vent pipe 2, and a complementary thermostat 3. The complementary thermostat 3 passes through the compensation vent pipe 2 and the furnace body 1, wherein: the Complementary thermostat 3 includes temperature regulation bin 4, condensation vacuum tube 5, mechanical vacuum tube 6, condensation vacuum pump 7, mechanical pumping vacuum pump 8, complementary thermostat 3 includes electric heating chip stack 9 set in temperature regulation bin 4 , the temperature sensor 13 is set in the temperature adjustment chamber 4, the compensation ventilation pipe 2 is connected to the condensation vacuum pump 7, the mechanical suction vacuum pipe 6 is connected to the mechanical suction vacuum pump 8, and the inlet of the mechanical suction vacuum pipe 6 is connected to the condensation suction vacuum pipe 5. The temperature chamber 4 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com