Multifunctional in-mold labeling mechanical arm and production line

An in-mold labeling and manipulator technology, applied in labeling machines, labels, packaging, etc., can solve the problems of complex overall structure, low production efficiency of the production line, shaking of label molds, etc., to achieve reduced connection components, high production efficiency, The effect of strong support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

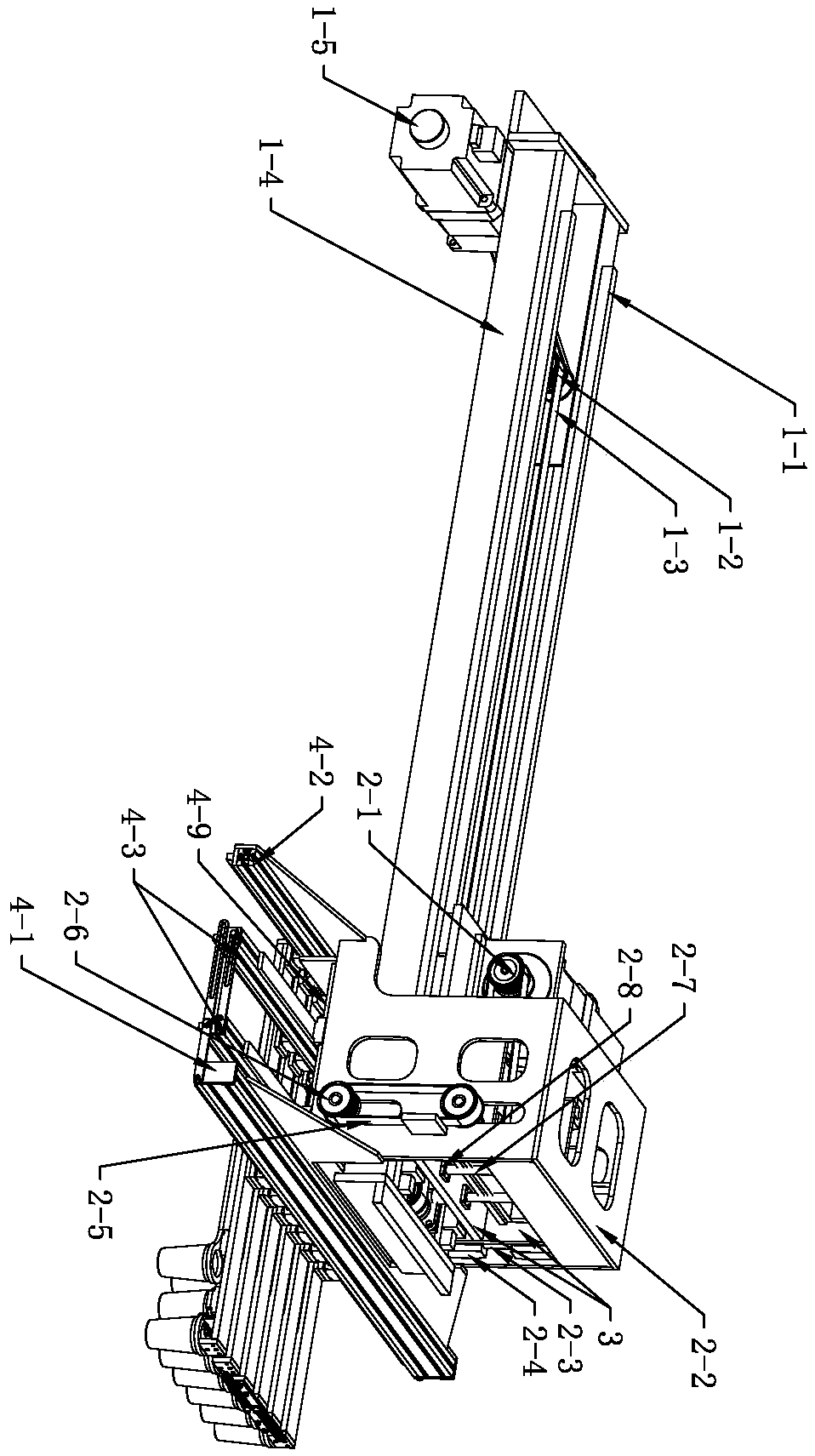

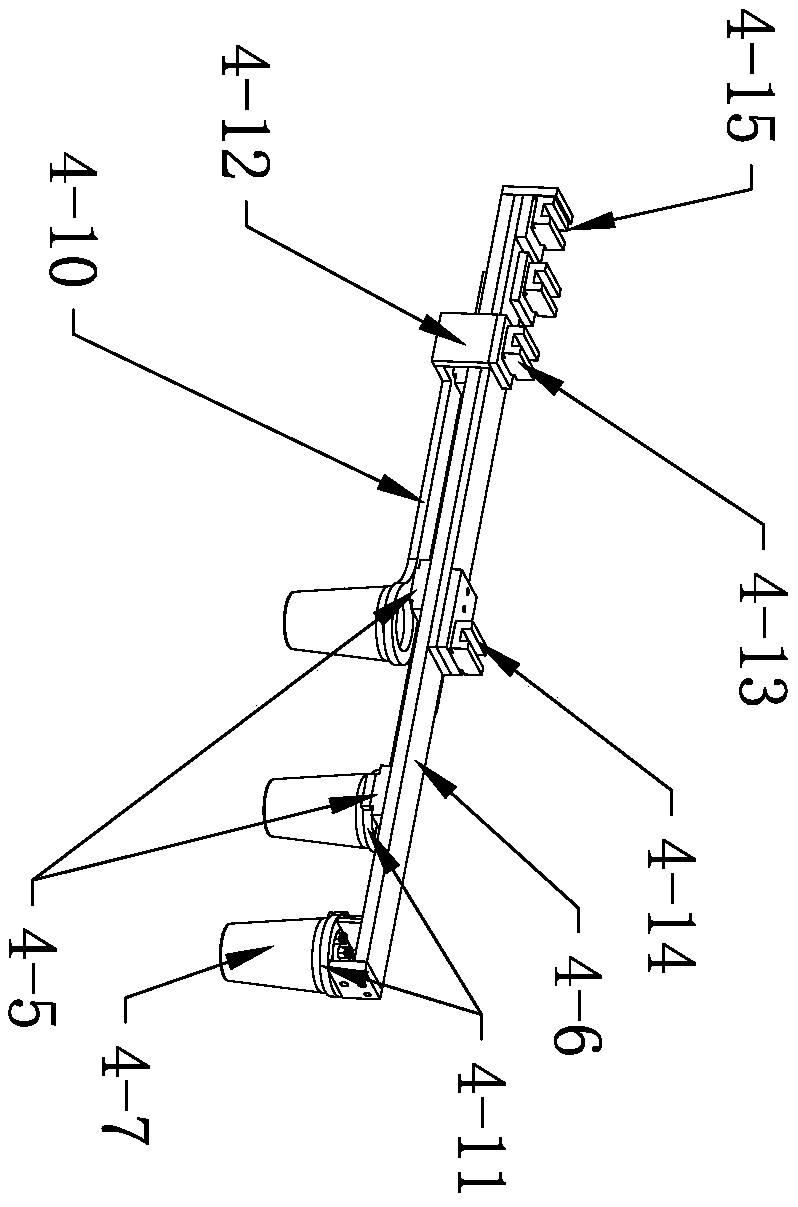

[0076] see Figure 1 to Figure 11The multifunctional in-mold labeling manipulator of this embodiment includes a translation mechanism, a lifting mechanism 2, a translation lifting support seat 3 and a label removal mechanism 4. Under the action of the translation mechanism and the lifting mechanism 2, the label removal mechanism 4 can be Translation and lifting movement. In this embodiment, the translation mechanism includes a translation support frame 1-4, a translation drive motor 1-5, a translation synchronous belt 1-3 and a translation synchronous wheel 1-2, and the two ends of the translation support frame 1-4 are respectively installed with translation synchronous Wheel 1-2, the translation synchronous wheel 1-2 is driven by the translation drive motor 1-5, the translation synchronous belt 1-3 is installed on the synchronous wheel, and translation guide rails 1-1 are respectively installed on both sides of the translation support frame 1-4, The translational lifting sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com