Special tooling platform for maintenance of folding arm disconnecting switch

A technology of isolating switches and tooling, which is applied in the direction of switchgear and electrical components, can solve the problems of simple structure, troublesome use, and poor applicability, and achieve the effects of convenient and effective fixing, convenient and flexible movement, and improved maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

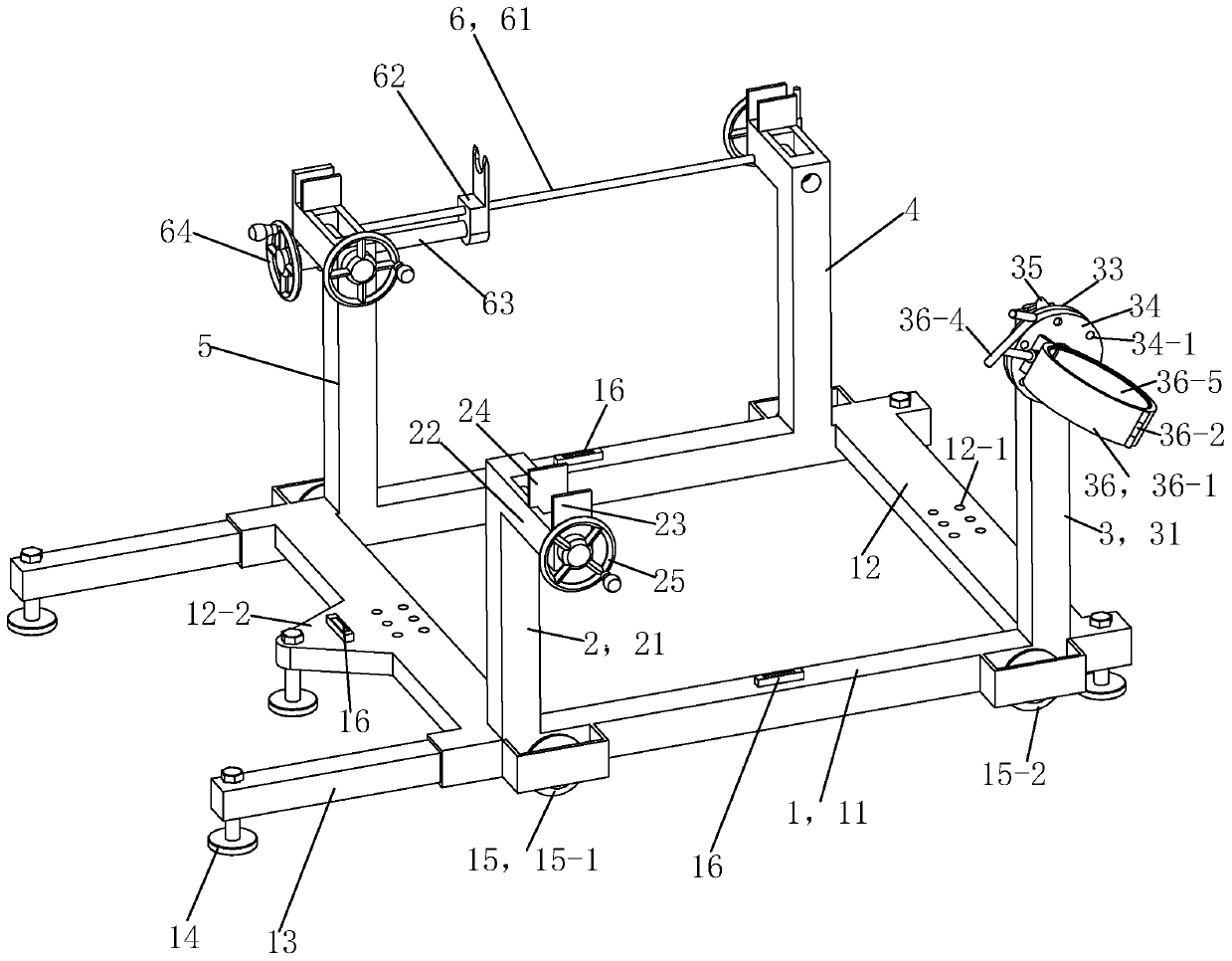

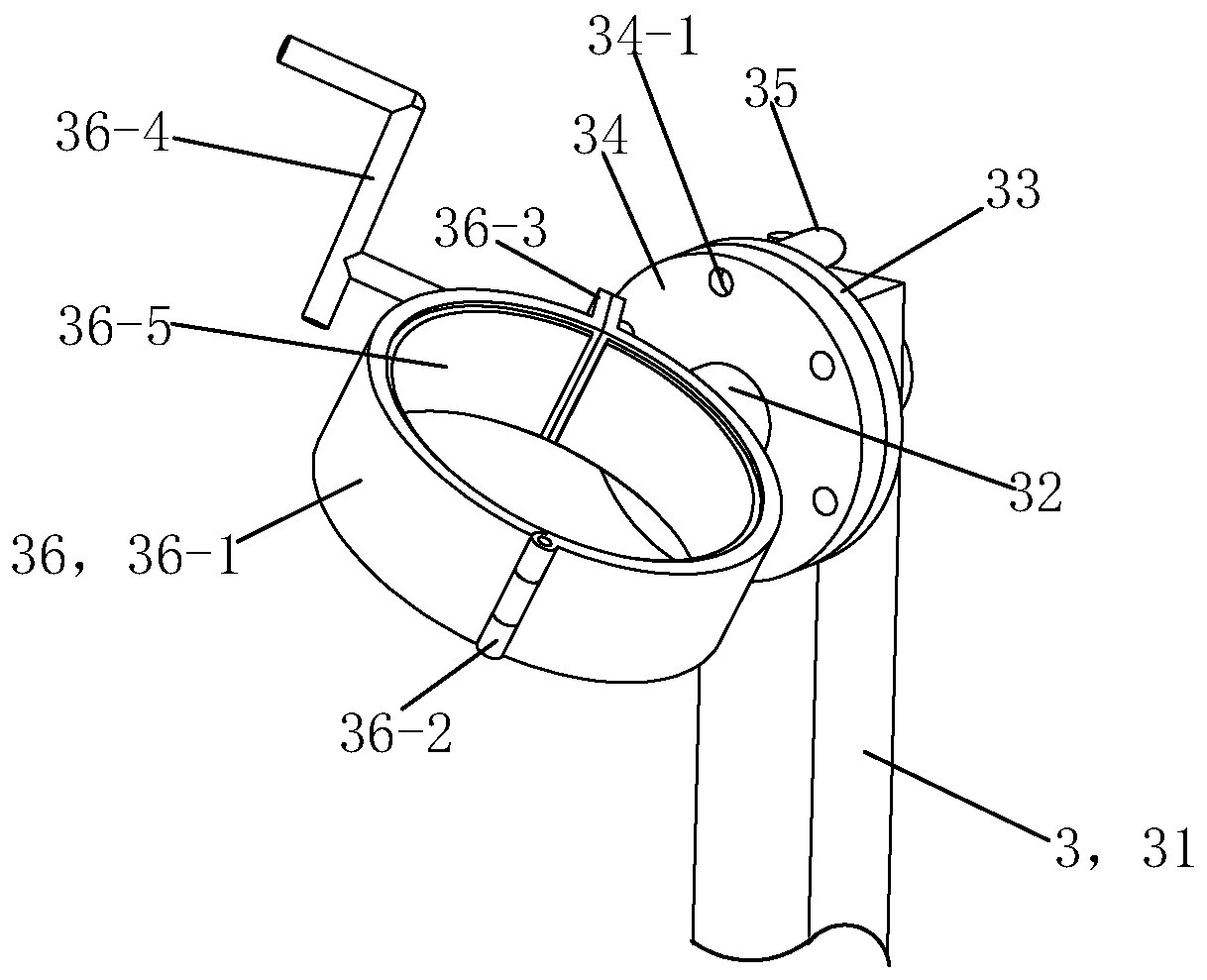

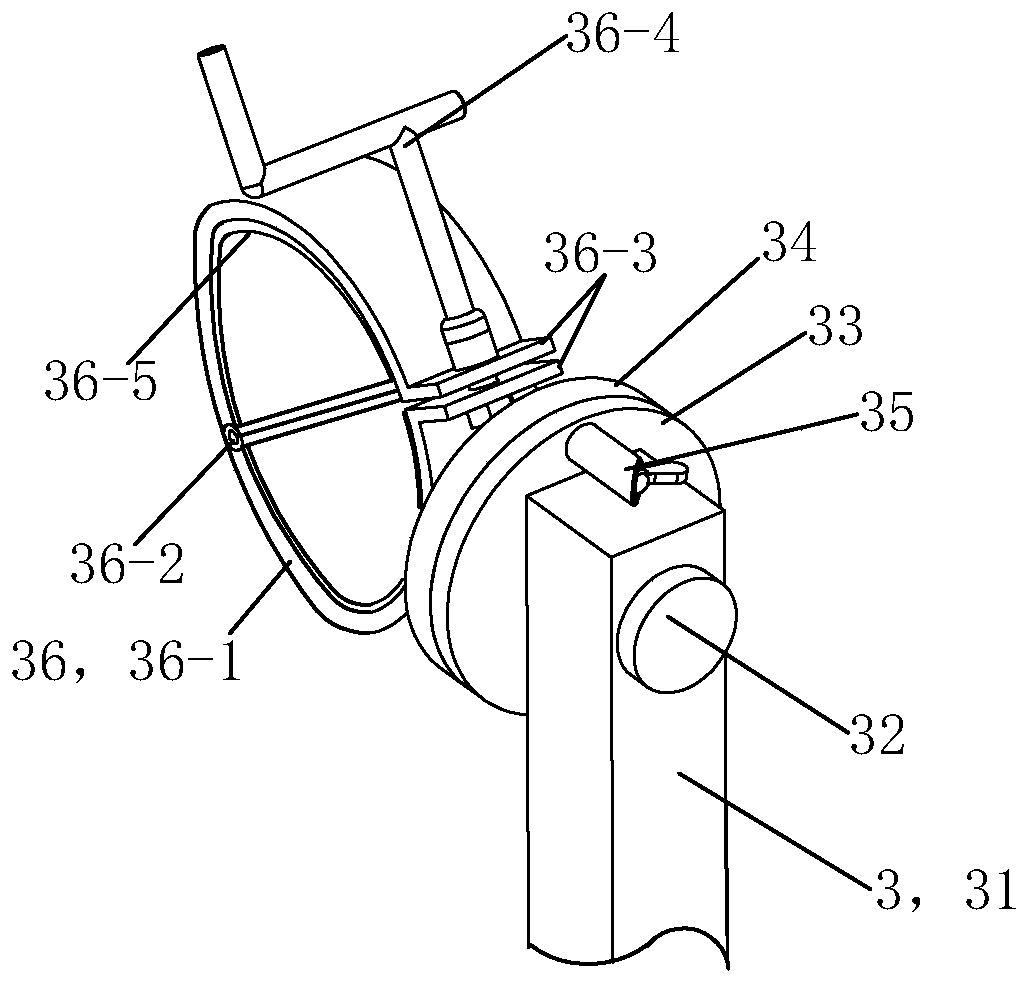

[0031] See figure 1 , the special tooling platform for overhauling the folding arm type isolating switch in this embodiment is mainly composed of a base 1, a first fixing part 2 of the upper conductive arm, a second fixing part 3 of the upper conductive arm, a first fixing part 4 for spring disassembly and assembly, a spring disassembly Install the second fixing part 5 and the spring compression assembly 6 to form.

[0032] Base 1 is mainly made up of beam 11, connecting beam 12, telescopic beam 13, adjustable supporting foot 14, walking wheel 15 and level 16.

[0033]Two beams 11 are arranged in parallel at the front and rear. In this embodiment, the beams 11 are preferably made of hollow high-strength square tubes, and the material of the beams 11 is preferably stainless steel. The two connecting beams 12 are arranged in parallel on the left and right, and the front and rear ends of the two connecting beams 12 are respectively connected vertically and fixedly with the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com