Design method of permanent magnet synchronous motor for vehicle

A permanent magnet synchronous motor and vehicle technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of wasteful design cycle and prolongation, and achieve the effect of reducing design cost and shortening design cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

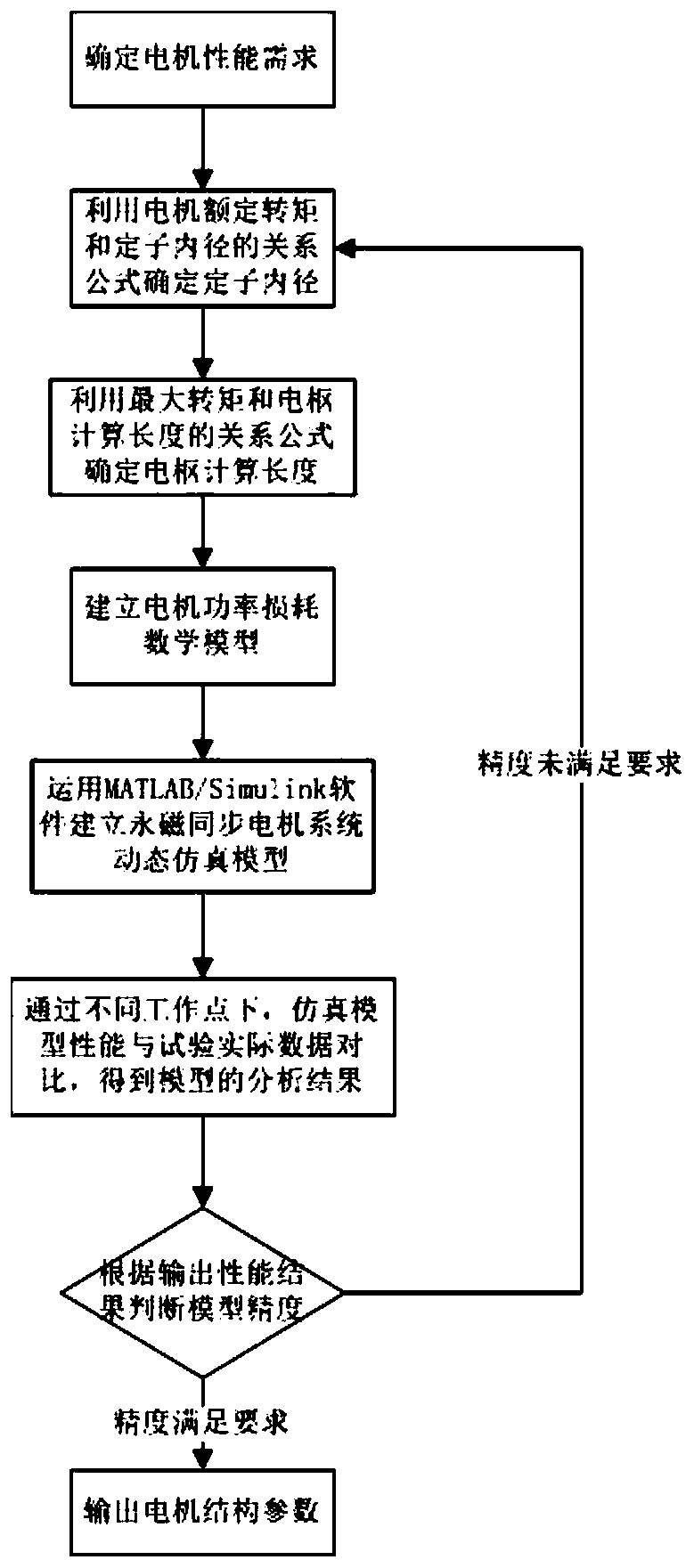

[0040] The method provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] like figure 1 Shown, the method provided by the present invention specifically comprises:

[0042] Step 1. Determine the performance requirement parameters of the motor;

[0043] Step 2, according to the relationship between the rated torque of the motor and the inner diameter of the stator, and the relationship between the maximum torque and the calculated length of the armature, determine the structural parameters of the stator and rotor of the motor according to the performance parameters;

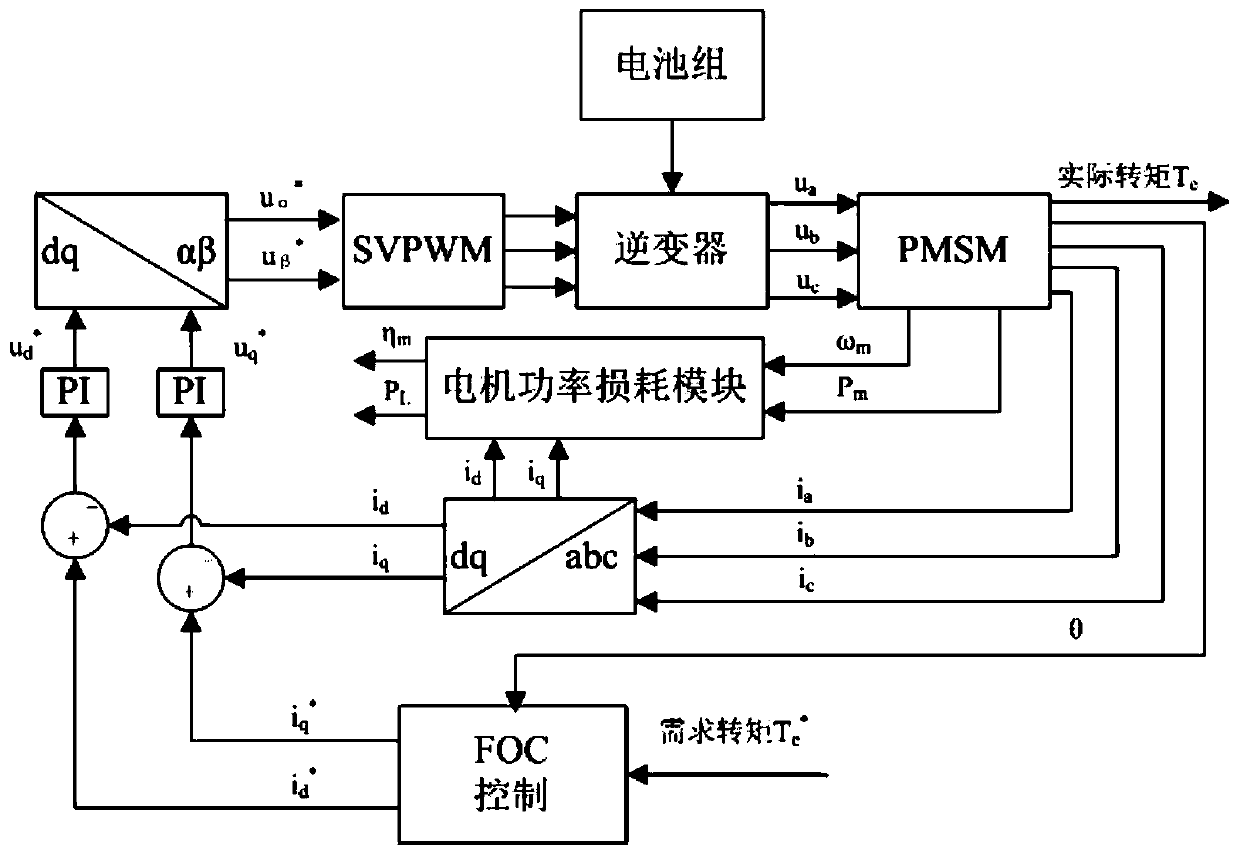

[0044] Step 3, using the performance requirement parameters and the motor stator and rotor structure parameters to establish a permanent magnet synchronous motor power loss mathematical model;

[0045] Step 4, establishing a permanent magnet synchronous motor system dynamic simulation model including the performance parameters, motor stator and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com