Automatic assembling system of automobile door lock connector, and working process of system

An automatic assembly, car door lock technology, applied in the assembly/disassembly of vehicle connectors and contacts, can solve the problems of difficult electronic components, poor connectivity between electronic components and housing hardware, inconvenient operation and observation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

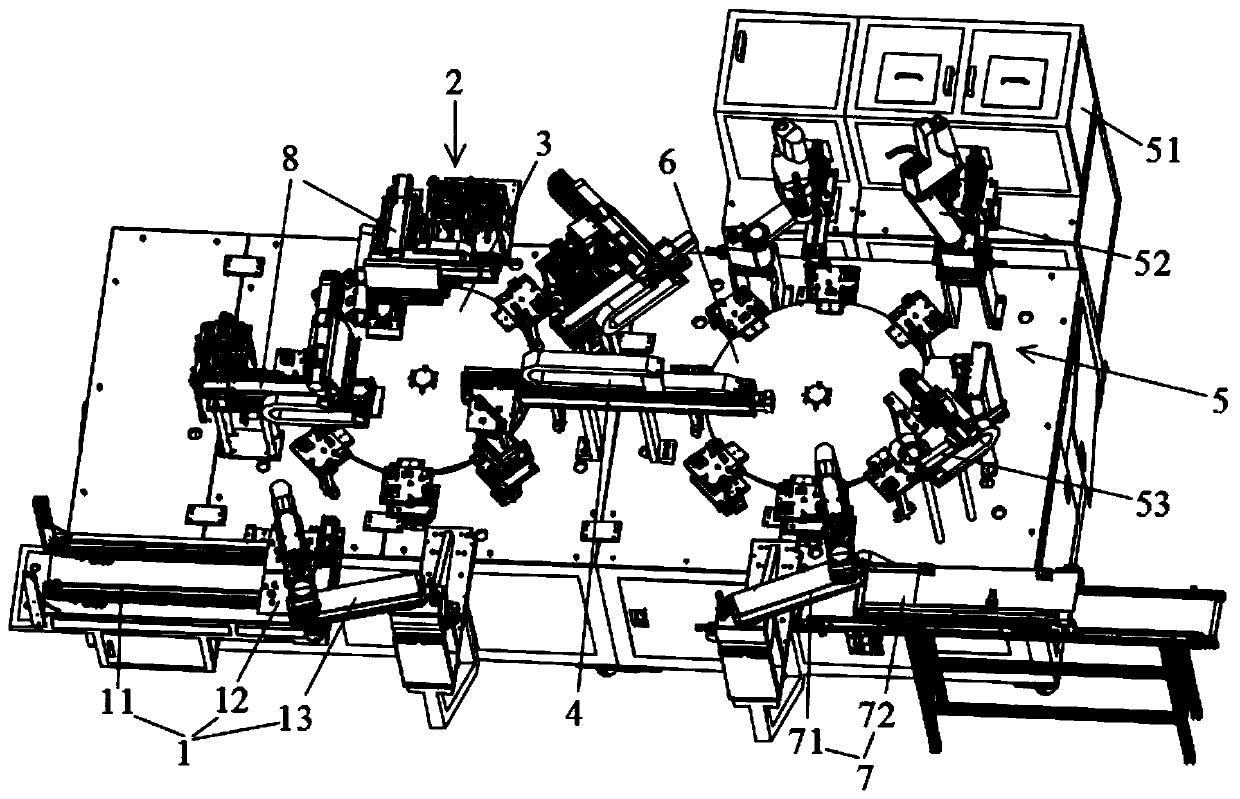

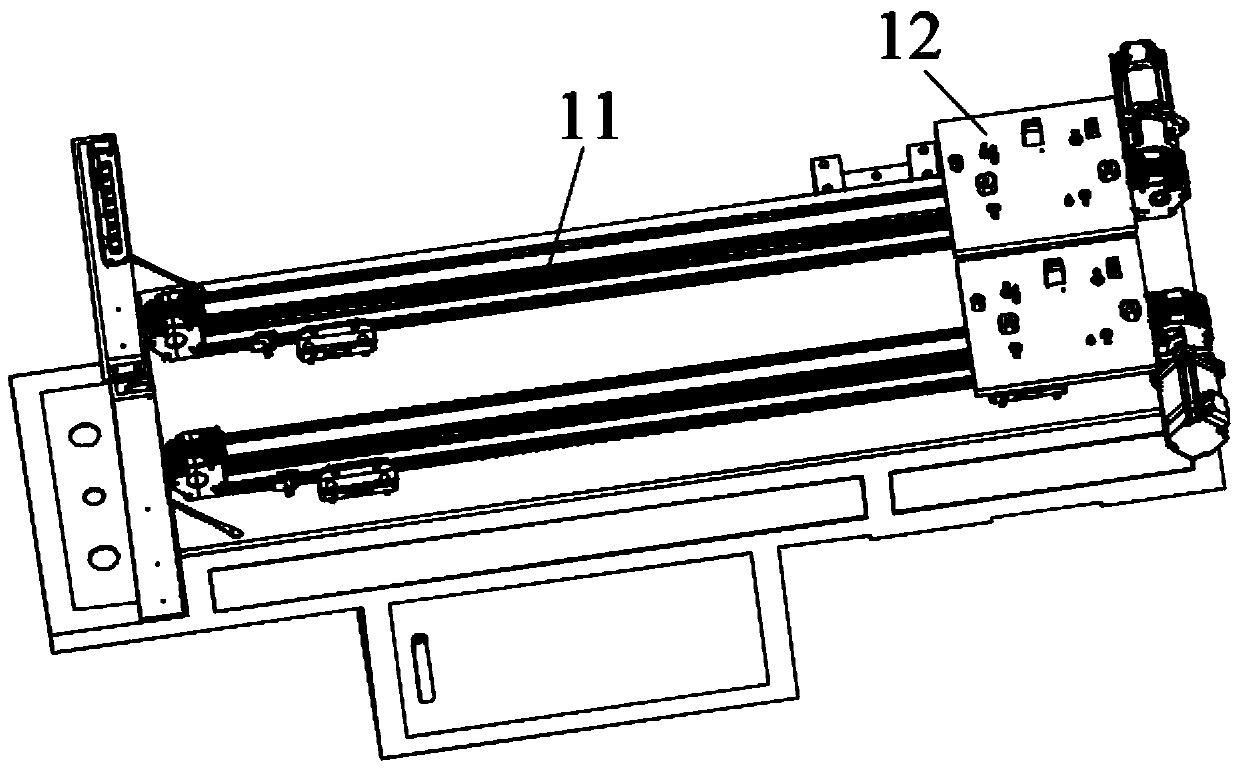

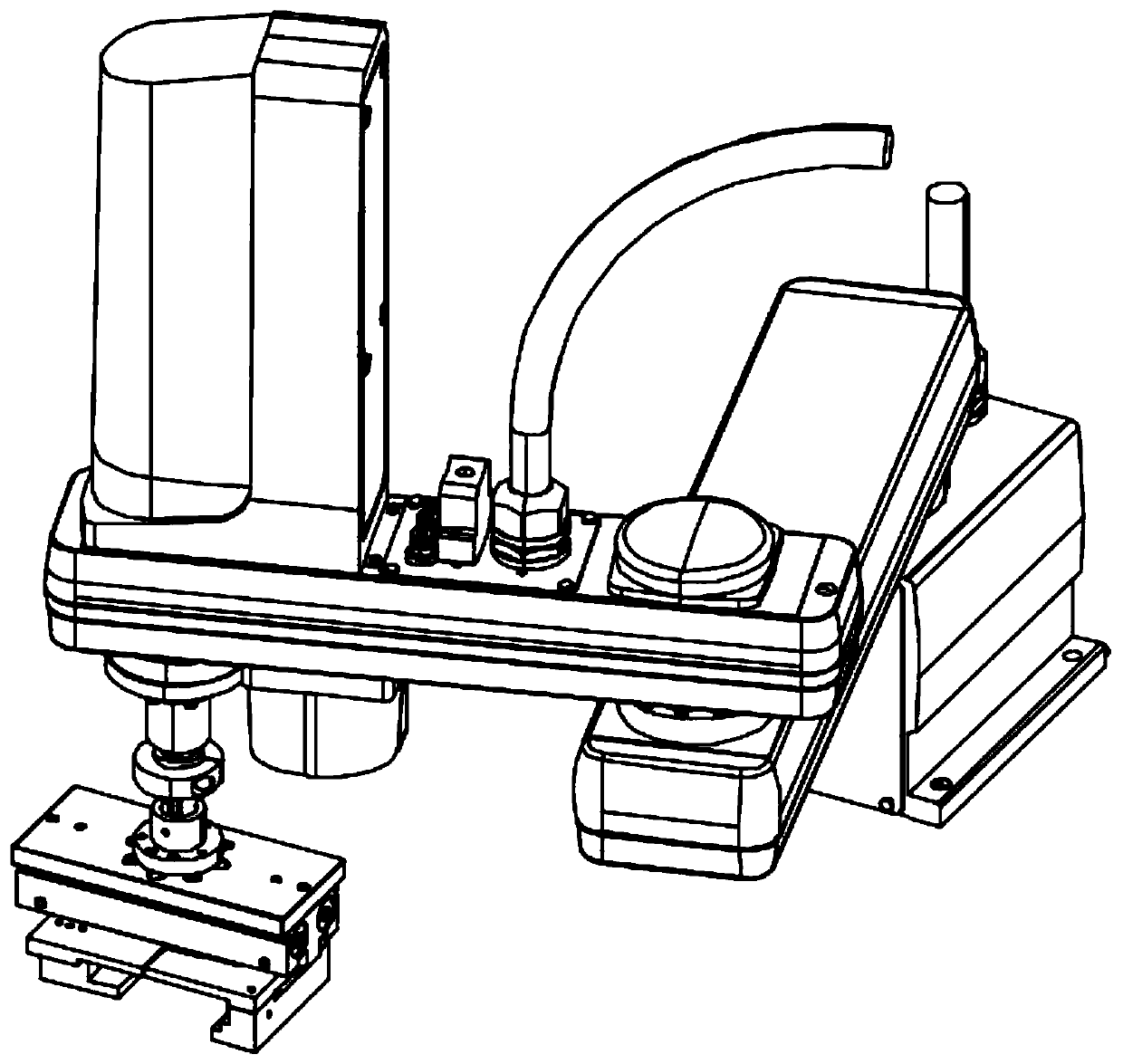

[0041] Such as Figure 1-11 As shown, an automatic assembly system for automobile door lock connectors, including a feeding device 1, a first assembly device 2, a first indexer 3, a handling device 4, a second assembly device 5, a second indexer 6 and a feeding device 7. The feeding device 1 is used to place the product on the first indexer 3, the first assembly device 2 is used to assemble the electronic components of the product on the first indexer 3, and the handling device 4 is used to place the product on the first indexer 3 The products are transported to the second indexer 6, the second assembly device 5 is used to assemble and detect the electronic components of the products on the second indexer 6, and the unloading device 7 is used to classify the products on the second indexer 6 after detection Material, the product flows through the feeding device 1, the first assembly device 2, the first indexer 3, the handling device 4, the second assembly device 5, the second i...

Embodiment 2

[0052] Such as Figure 1-11 Shown, the workflow of the automatic assembly system of a kind of embodiment 1 or 2 or 3 automobile door lock connectors, comprises the following steps:

[0053] S1. The feeding device 1 places the product on the first indexer 3;

[0054] S2. The first assembly device 2 assembles electronic components on the products on the first indexer 3;

[0055] S3, the transport device 4 transports the product on the first indexer 3 to the second indexer 6;

[0056] S4. The second assembly device 5 assembles and detects electronic components on the products on the second indexer 6;

[0057] S5. The unloading device 7 is used for sorting and unloading after detecting the products on the second indexer 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com