Rod-like nickel hydroxide electrode material, preparation method and prepared supercapacitor

A supercapacitor, nickel hydroxide technology, used in nickel oxide/nickel hydroxide, hybrid/electric double layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of rate performance, measured specific capacity and cycle stability is not very ideal, The problems of easy escape of intercalated anions and low electronic conductivity have achieved the effect of solving practical application problems, easy industrial scale-up and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

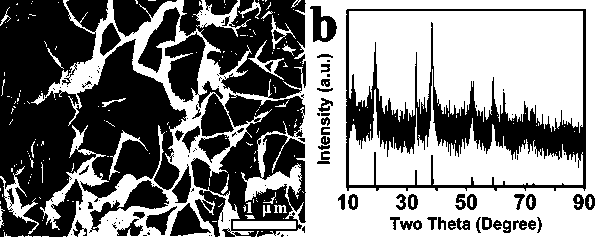

[0040] This embodiment provides a method for preparing a rod-shaped nickel hydroxide electrode material, and the preparation steps are as follows:

[0041] (1) Weigh 5 mmol of nickel nitrate, dissolve in 20 mL of distilled water, and place in 80 o Carry out magnetic stirring in the oil bath device of C;

[0042] (2) take by weighing the sodium chloride of 16 g, under magnetic stirring effect, join above-mentioned nickel nitrate and dissolve in;

[0043] (3) Add 50 mL of ammonia water dropwise to the above-mentioned nickel nitrate aqueous solution under magnetic stirring, then use a constant temperature oil bath, and evaporate the above-mentioned solution to a viscous state by solvent evaporation method to end the reaction;

[0044] (4) Transfer the above-mentioned viscous product to a centrifuge tube with distilled water and ethanol, and repeatedly centrifuge and wash to remove excess ammonia and sodium chloride; then dry and collect the precipitate to obtain the target produ...

Embodiment 2

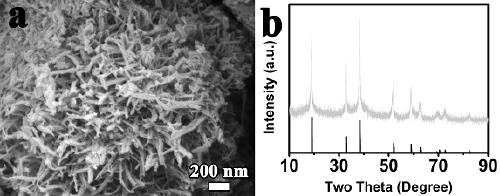

[0047] This embodiment provides a method for preparing a rod-shaped nickel hydroxide electrode material, and the preparation steps are as follows:

[0048] (1) Weigh 2 mmol of nickel nitrate, dissolve in 30 mL of distilled water, and place in 60 o Carry out magnetic stirring in the oil bath device of C;

[0049] (2) take by weighing the sodium chloride of 12 g, under magnetic stirring effect, join above-mentioned nickel nitrate and dissolve in;

[0050] (3) Add 40 mL of ammonia water dropwise to the above-mentioned nickel nitrate aqueous solution under magnetic stirring, and then use a constant temperature oil bath to evaporate the above-mentioned solution to a viscous state by solvent evaporation method to end the reaction;

[0051] (4) Transfer the above-mentioned viscous product to a centrifuge tube with distilled water and ethanol, and repeatedly centrifuge and wash to remove excess ammonia and sodium chloride; then dry and collect the precipitate to obtain the target pro...

Embodiment 3

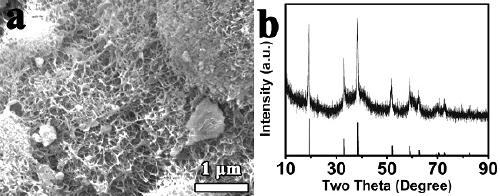

[0054] This embodiment provides a method for preparing a rod-shaped nickel hydroxide electrode material, and the preparation steps are as follows:

[0055] (1) Weigh 8 mmol of nickel nitrate, dissolve in 40 mL of distilled water, and place in 80 o Carry out magnetic stirring in the oil bath device of C;

[0056] (2) take by weighing the sodium chloride of 8 g, under magnetic stirring effect, join above-mentioned nickel nitrate and dissolve in;

[0057] (3) Add 30 mL of ammonia water dropwise to the above-mentioned nickel nitrate aqueous solution under magnetic stirring, and then use a constant temperature oil bath to evaporate the above-mentioned solution to a viscous state by solvent evaporation method to end the reaction;

[0058] (4) Transfer the above-mentioned viscous product to a centrifuge tube with distilled water and ethanol, and repeatedly centrifuge and wash to remove excess ammonia and sodium chloride; then dry and collect the precipitate to obtain the target prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com