Intelligent wire harness design method and device

A design method and wire harness technology, applied in the field of intelligent wire harness design methods and devices, can solve the problems of non-functional ductility, poor consistency, increased repetitive work, etc., to reduce human workload, have functional ductility, and reduce omissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

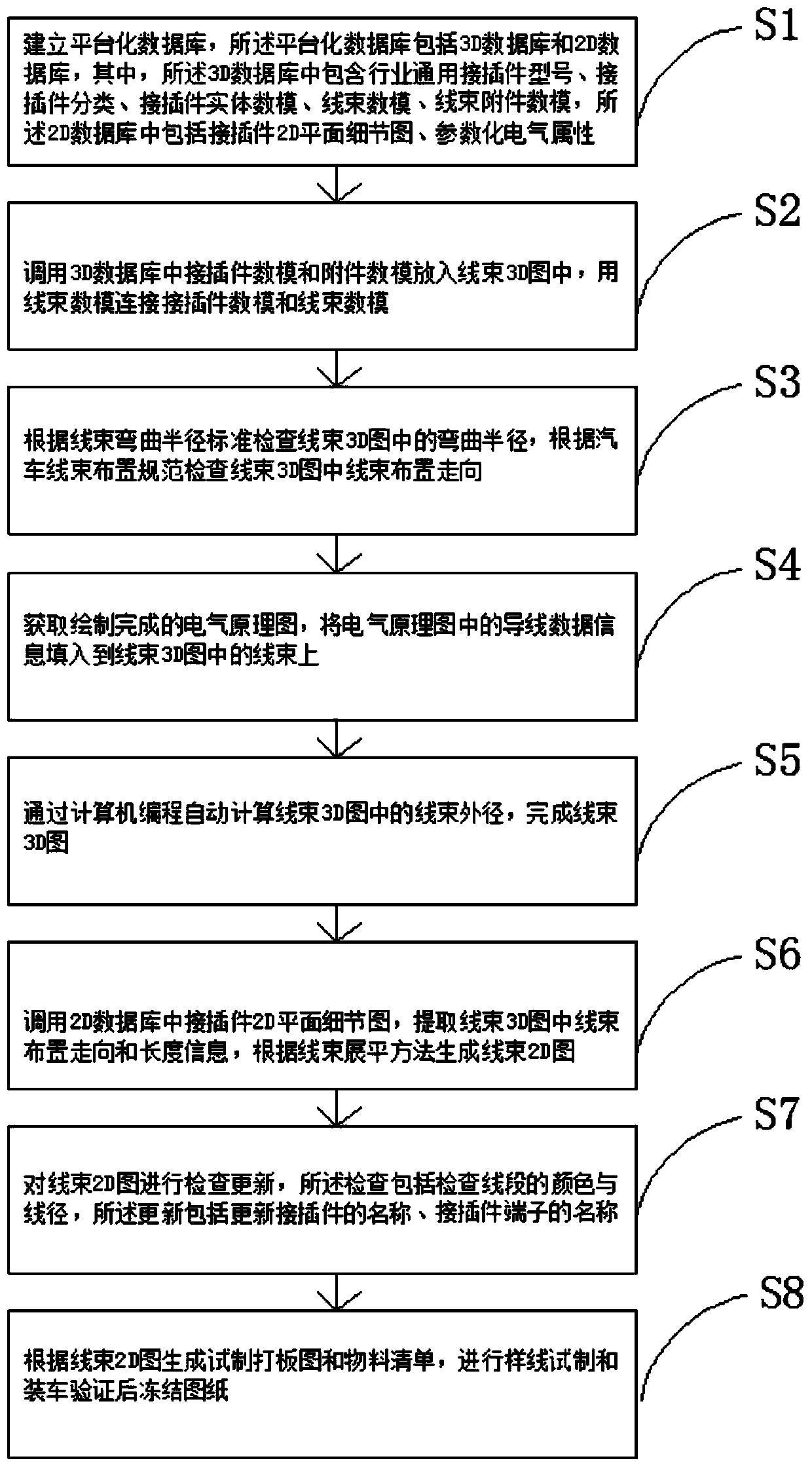

[0044] This embodiment provides an intelligent wiring harness design method, please refer to figure 1 , figure 1 It is a schematic flow chart of an intelligent wiring harness design method in this embodiment, and the specific steps of the method are as follows:

[0045] S1. Establish a platform-based database, the platform-based database includes a 3D database and a 2D database, wherein the 3D database includes industry-wide connector models, connector classifications, connector physical digital models, wire harness digital models, and wire harness accessories The 2D database includes a 2D plane detail drawing of the connector and parameterized electrical properties. The platform-based database is not limited to the above content, and the content of the database can also be continuously added in the process of later use.

[0046] S2. Call the connector digital model and the accessory digital model in the 3D database and put them into the wire harness 3D diagram, and use th...

Embodiment 2

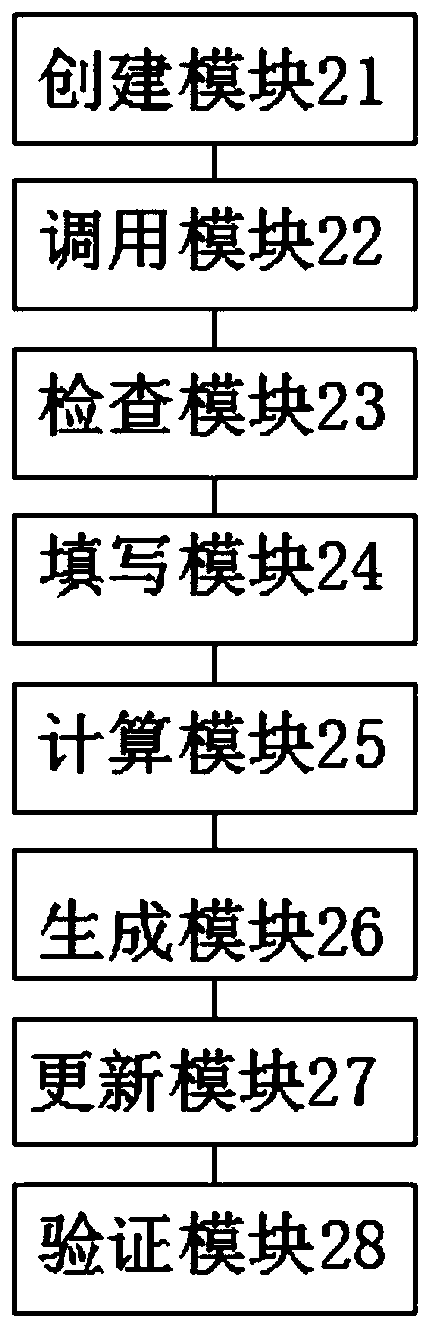

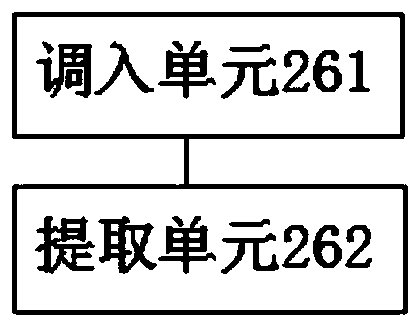

[0081] This embodiment provides an intelligent wiring harness design device on the basis of Embodiment 1, which is used to implement the method of Embodiment 1 above. Please refer to figure 2 , figure 2 It is a schematic structural diagram of an intelligent wiring harness design device in this embodiment, which includes: a creation module 21, a call module 22, a check module 23, a filling module 24, a calculation module 25, a generation module 26, an update module 27, and a verification module 28 ;

[0082] Create a module 21 for creating a platform database;

[0083] The calling module 22 is used to call the digital-analog of the connector and the digital-analog of the accessories in the 3D database; the calling module also includes a connection unit, which is used to connect the digital-analog of the connector and the digital-analog of the wire harness.

[0084] An inspection module 23, configured to inspect the bending radius of the wire harness and the layout specifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com