Modeling method for process reliability of marine diesel engine body machining process

A marine diesel engine and processing technology, which is applied in data processing applications, computer-aided design, special data processing applications, etc., can solve problems such as research without the reliability of processing technology, and achieve high engineering application value, high solution efficiency, theoretical simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

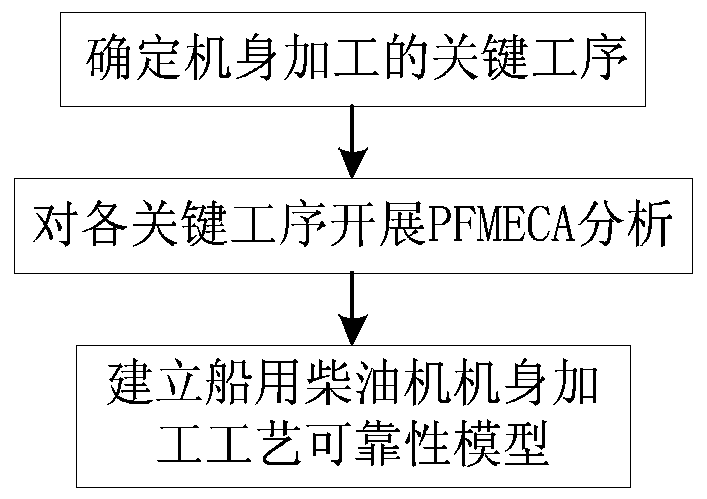

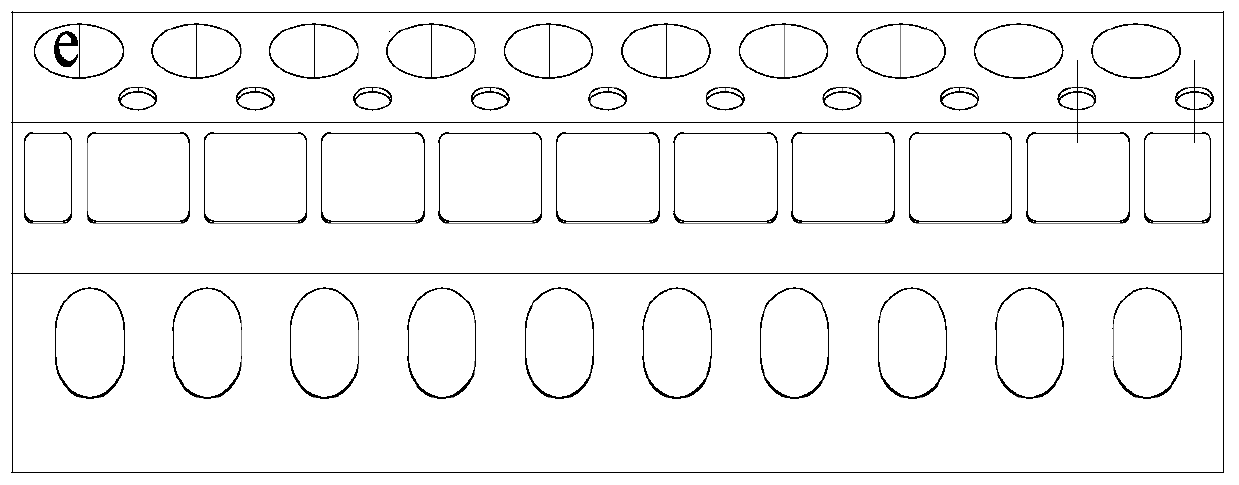

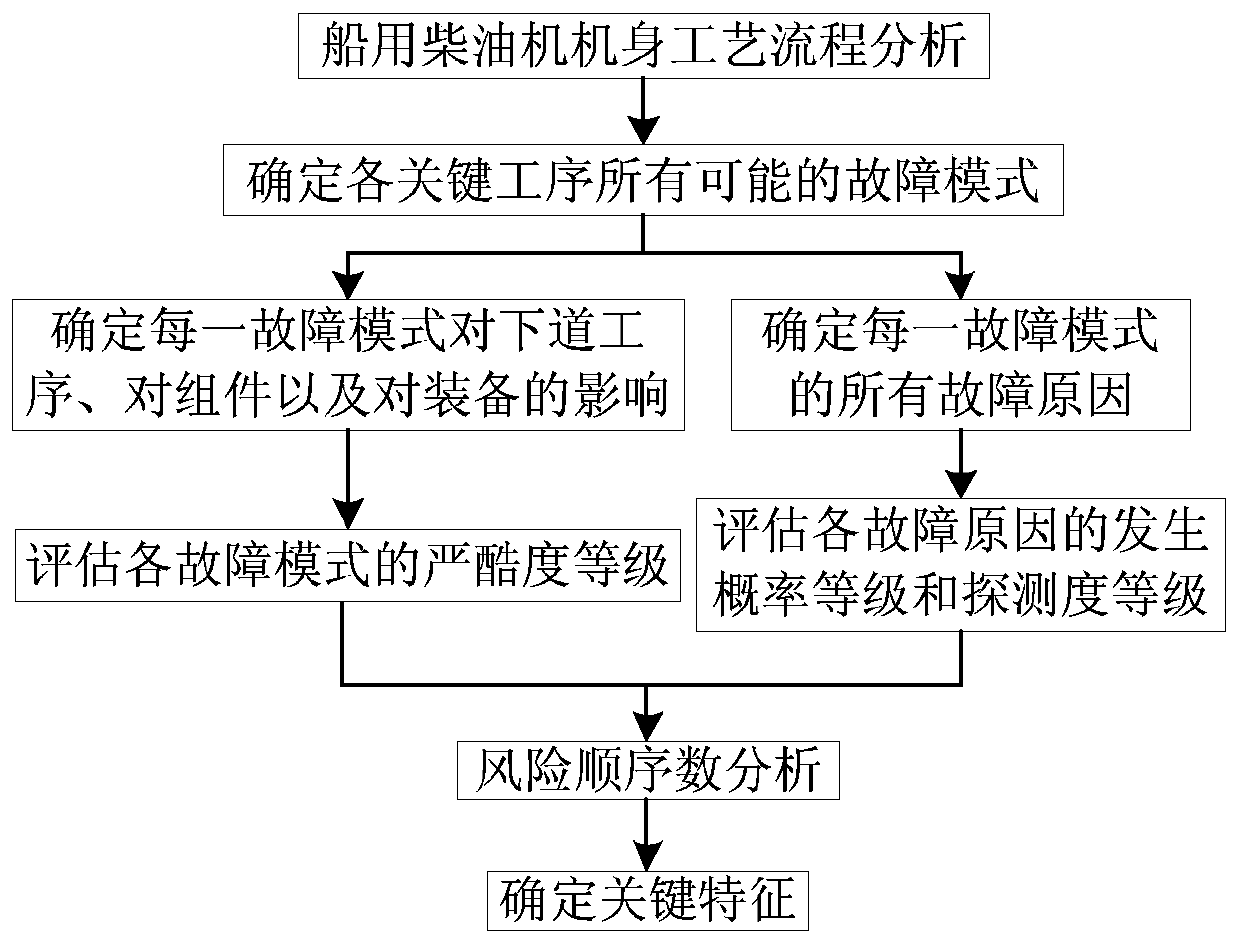

[0036] In this embodiment, the reliability evaluation of a certain type of marine diesel engine fuselage processing technology is taken as an example. The overall evaluation process is as follows: figure 1 Shown. The schematic diagram of the fuselage of this type of marine diesel engine is as figure 2 with Picture 8 As shown, a is the top surface, b is the camshaft hole, c is the crankshaft hole, d is the bottom surface, and e is the cylinder hole.

[0037] Step 1: According to the marine diesel engine fuselage processing process, determine the key process of fuselage processing, the specific process is:

[0038] ①Fill in the processing flow chart of marine diesel engine fuselage:

[0039] The marine diesel engine has a complicated structure and numerous processes. Figure 5 The shown machining process flow chart of a certain type of marine diesel engine fuselage visually shows the process characteristics and results related to each process;

[0040] Figure 5 For a certain type of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com