A Hall Current Sensor Circuit with Double Hall Element Structure

A dual Hall element, sensor circuit technology, applied in the direction of measuring current/voltage, measuring current only, voltage/current isolation, etc., can solve problems such as large circuit differences, improve accuracy and linearity, and reduce zero drift Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

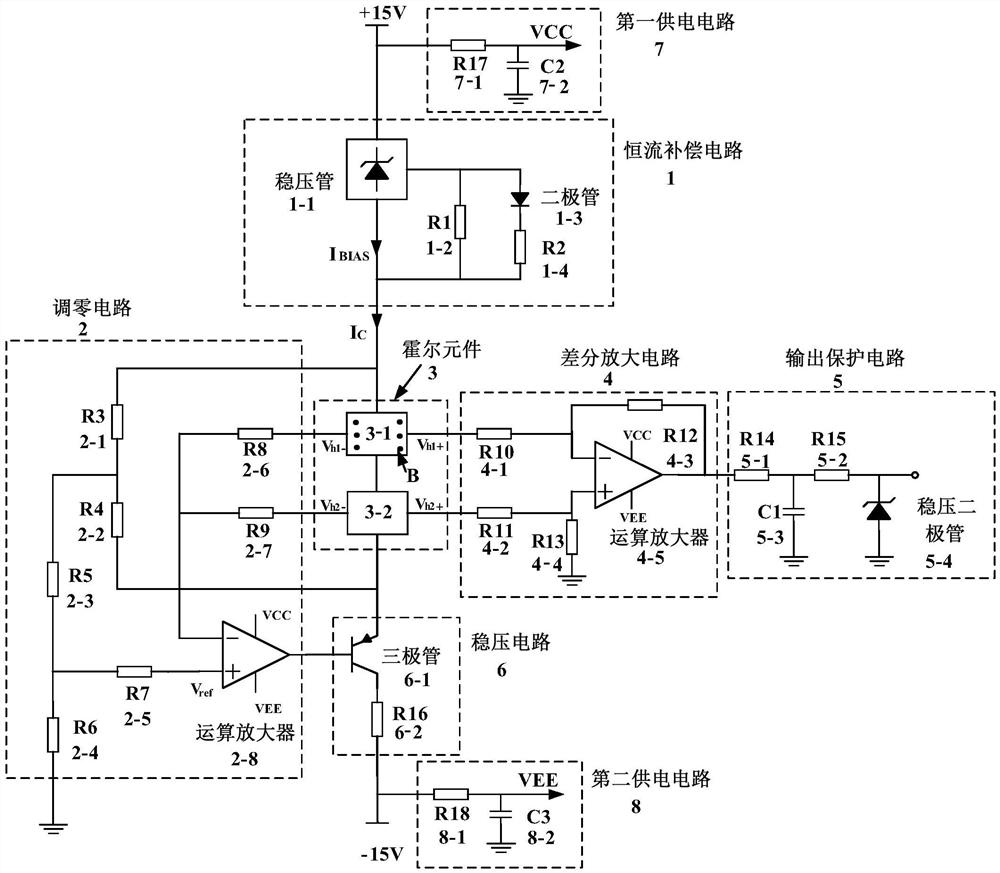

[0020] according to figure 1 As shown, the present invention proposes an open-loop Hall current sensor circuit with a dual Hall element structure, which adopts a ±15V dual power supply mode, and specifically includes a constant current compensation circuit 1, a zeroing circuit 2, a Hall element module 3, A differential amplifier circuit 4 , an output protection circuit 5 , a voltage stabilizing circuit 6 , a first power supply circuit 7 and a second power supply circuit 8 .

[0021] The constant current compensation circuit 1 is composed of a three-terminal regulator tube 1-1, a resistor R1, a diode 1-3 and a resistor R2. The three-terminal voltage regulator tube 1-1 selects a high-precision voltage regulator tube with an output reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com