Refrigeration system with drying function, drying device and operation control method

A technology of refrigeration system and drying function, which is applied in the field of refrigeration system and drying device with drying function, and can solve problems such as the inability to realize efficient operation of the system in the drying stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

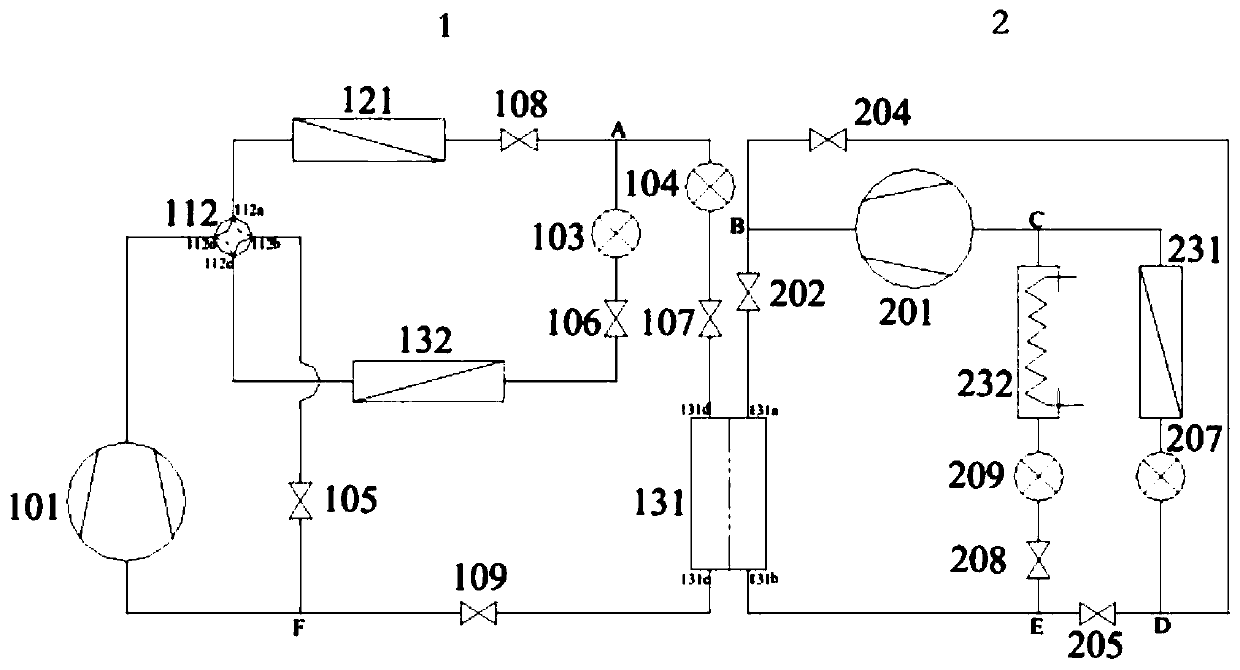

[0029] Such as figure 1 As shown, a refrigeration system with a drying function includes a first subsystem 1 and a second subsystem 2. The two subsystems are stacked together through a condensing evaporator 131. The refrigerant in the first subsystem is preferably medium High-temperature refrigerants, whose critical temperature is not higher than 200°C, can be one or a combination of two or more of the following: R134(A), R1234ze(Z), R1234ze(E), R1233zd(E), R245fa; The refrigerant in the second subsystem is preferably normal temperature or low temperature refrigerant, its critical temperature is not higher than 120°C, and it can be one or a combination of two or more: R32, R410A, R290.

[0030] The specific cooling system optimization scheme is as follows:

[0031] The first sub-system 1 includes a first refrigeration cycle formed by sequentially connecting the first compressor 101, the first heat exchanger 121, the first throttling device 104, the condensing evaporator 131 a...

Embodiment 2

[0048] An example of an operation control method for the refrigeration system in Embodiment 1 has the following control:

[0049] When the temperature Tin of the drying room is less than the preset temperature T1 and defrosting is not required, the temperature inside the drying room is relatively low. At this time, the cascade heat pump cycle can be used to quickly heat up the drying room, so that the first subsystem 1 and the second subsystem 2 Operation, control the valve of the first subsystem so that the flow direction of the refrigerant in the first subsystem 1 is the first compressor 101, the first heat exchanger 121, the first throttling device 104, the condensing evaporator 131, the evaporator side channel and The first compressor, the flow direction of the refrigerant in the second subsystem are the second compressor, the condenser side channel of the condensing evaporator, the third throttling device, the evaporator and the second compressor.

[0050] When the drying...

Embodiment 3

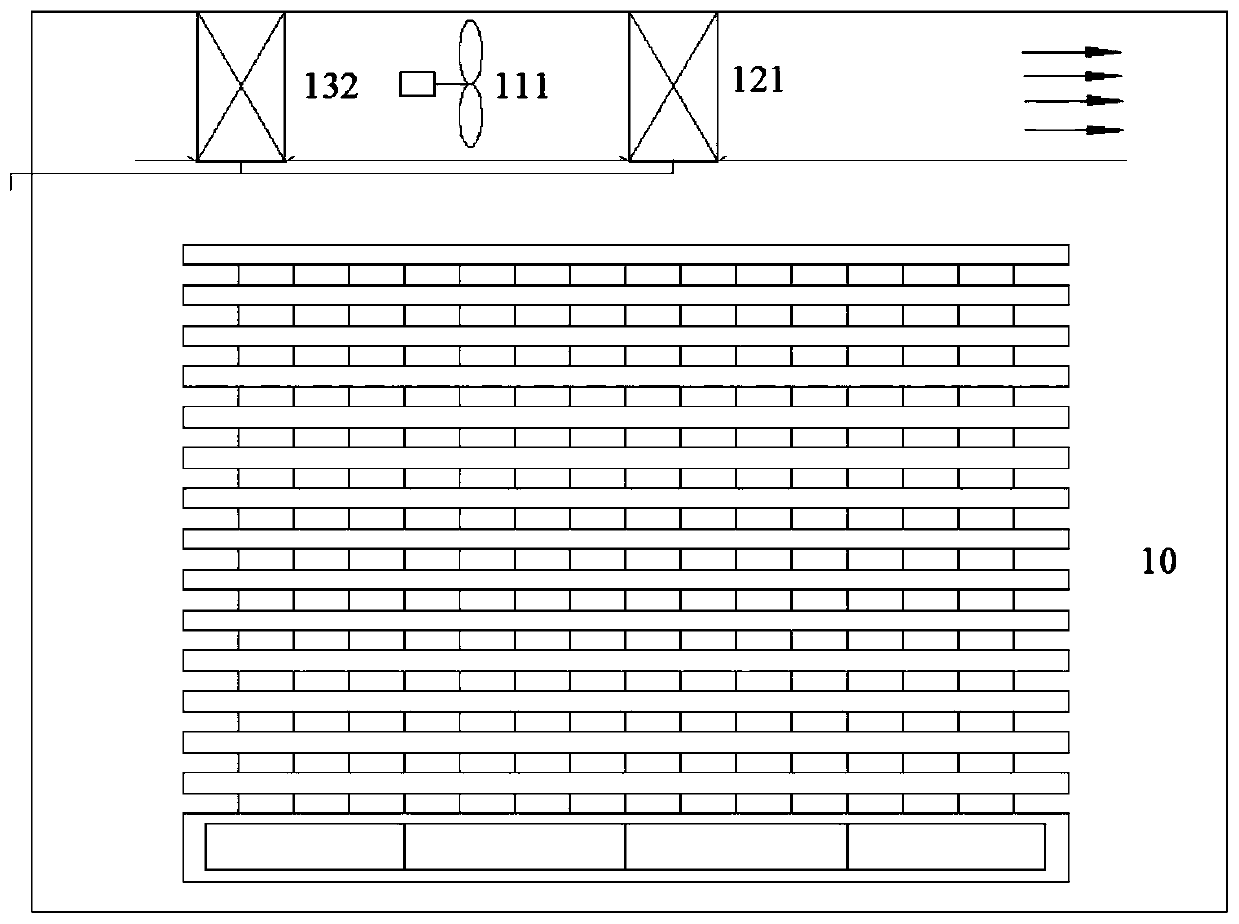

[0054] Such as figure 2 As shown, a drying device has a drying room and a refrigeration system, adopts the refrigeration system with drying function or the operation control method of the above-mentioned embodiment, and the first heat exchanger 121 and the second heat exchanger 132 are arranged in the drying in the room.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical temperature | aaaaa | aaaaa |

| Critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com