Driving mechanism of longitudinal lateral moving type movable bridge

A driving mechanism and translational technology, which is applied in bridges, pedestrian bridges, bridge forms, etc., can solve problems such as inability to adapt to floating deformation and safety requirements, poor deformation of mobile bridges and main structures, and large spans of longitudinal translational open bridges. Achieve the effects of enhanced anti-overturning ability, good stability, and good deformation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

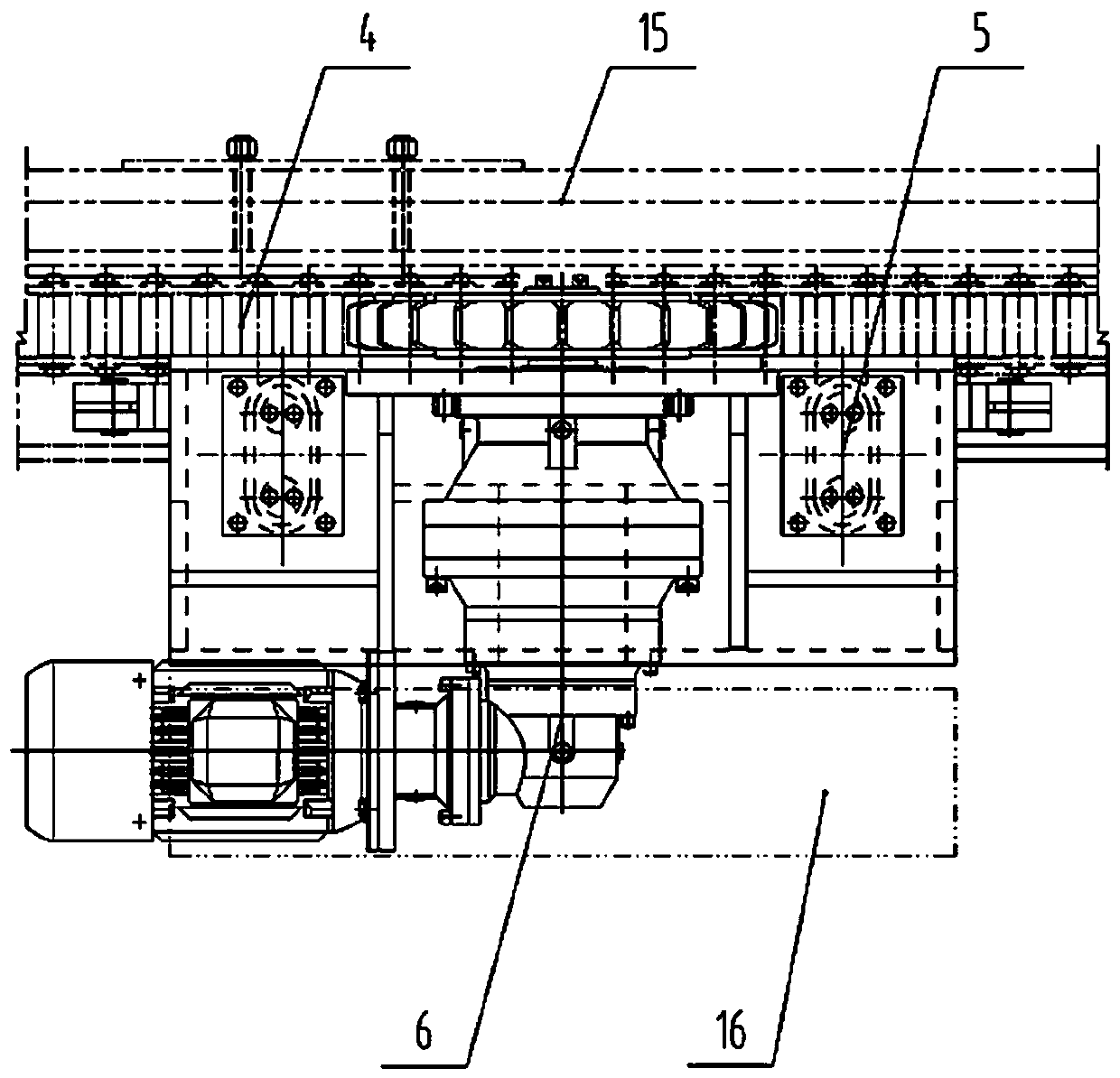

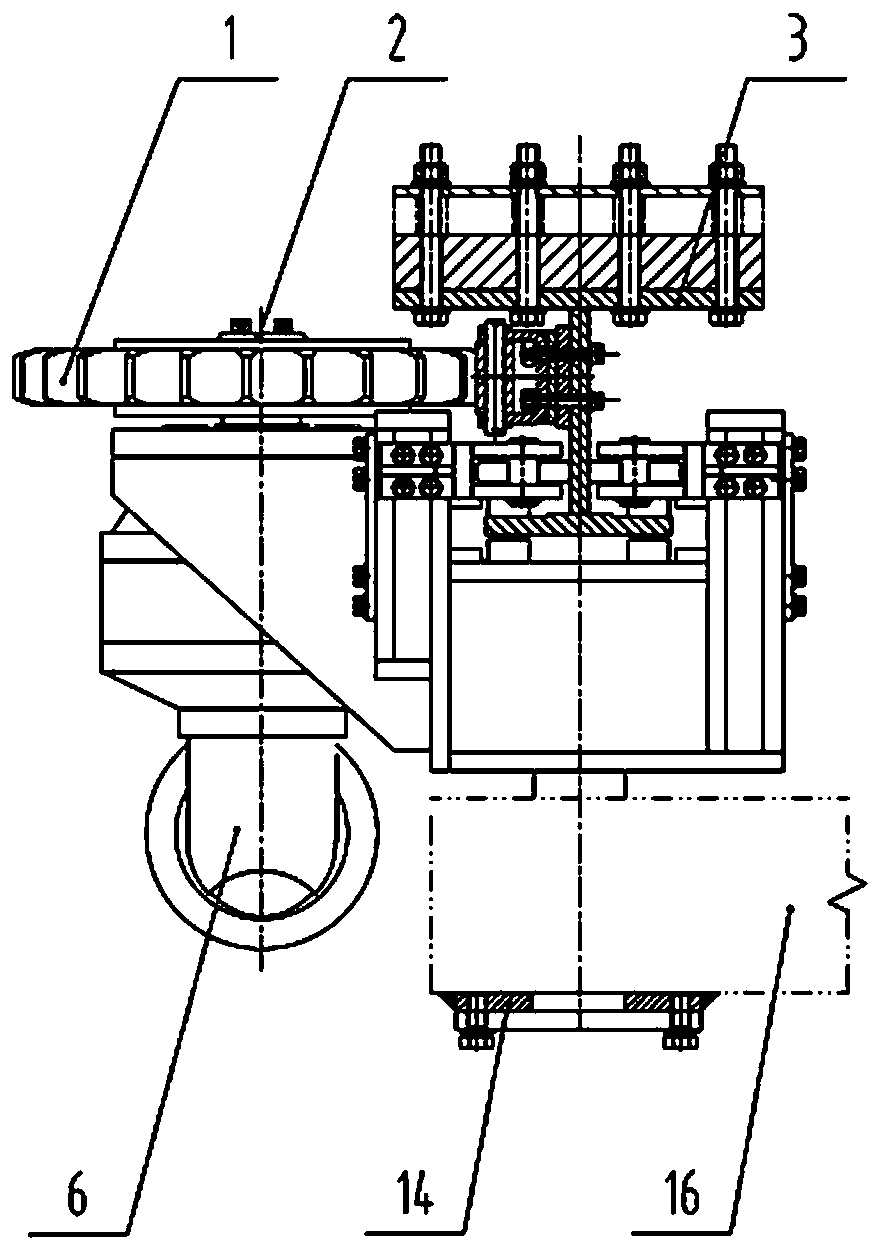

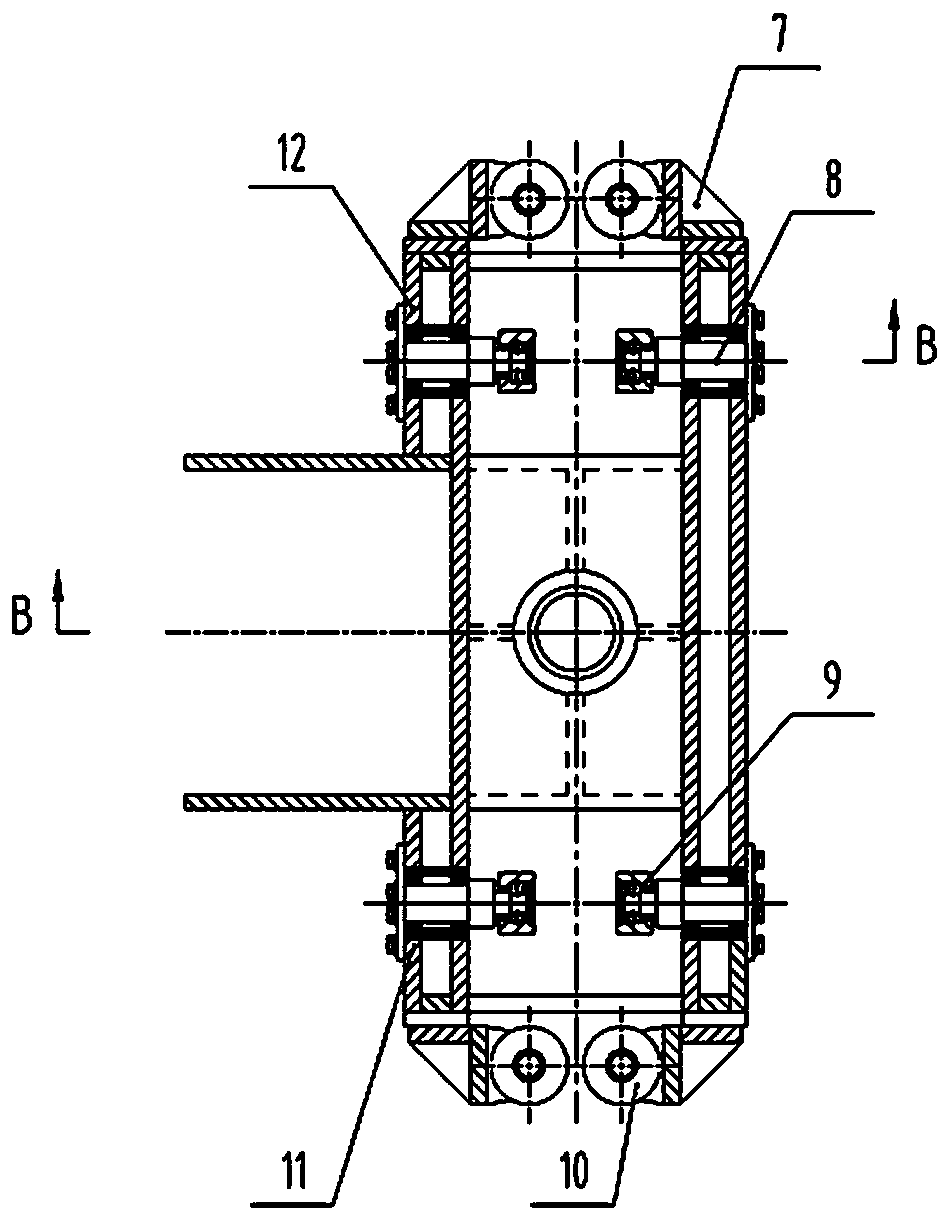

[0033] A drive mechanism for a longitudinal translation open bridge, such as Figure 1-Figure 4As shown, the drive mechanism includes a drive track 3, a chain drive, a fixed bridge 15, a movable bridge 16 and a drive slider frame 12, the drive track is fixed on the fixed bridge 15, and the chain drive includes a belt There is a geared motor 6 and a chain track 4 with an output shaft, the output shaft of the geared motor is provided with a sprocket 1 with gear teeth, and the sprocket 1 meshes with the chain track 4 to drive the drive slider frame 12 walk along the drive track 3, the chain track 4 is fixed on the drive track 3, the reduction motor 6 is fixed on the drive slider frame 12, and the upper end of the drive slider frame 12 passes through the horizontal and the vertical guide mechanism are suspended on the driving track 3, the lower end of the driving slider frame 12 is connected with the moving bridge 16 through a vertical large pin 13, and the lower end of the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com