Central air lift of multi-section vertical variable diameter guide cylinder

A technology of loop reactor and guide tube, which is applied in multi-stage water treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of high energy consumption in occupied area, low clarity of effluent water, and low space efficiency and other problems, to achieve the effect of small footprint, improved utilization rate, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

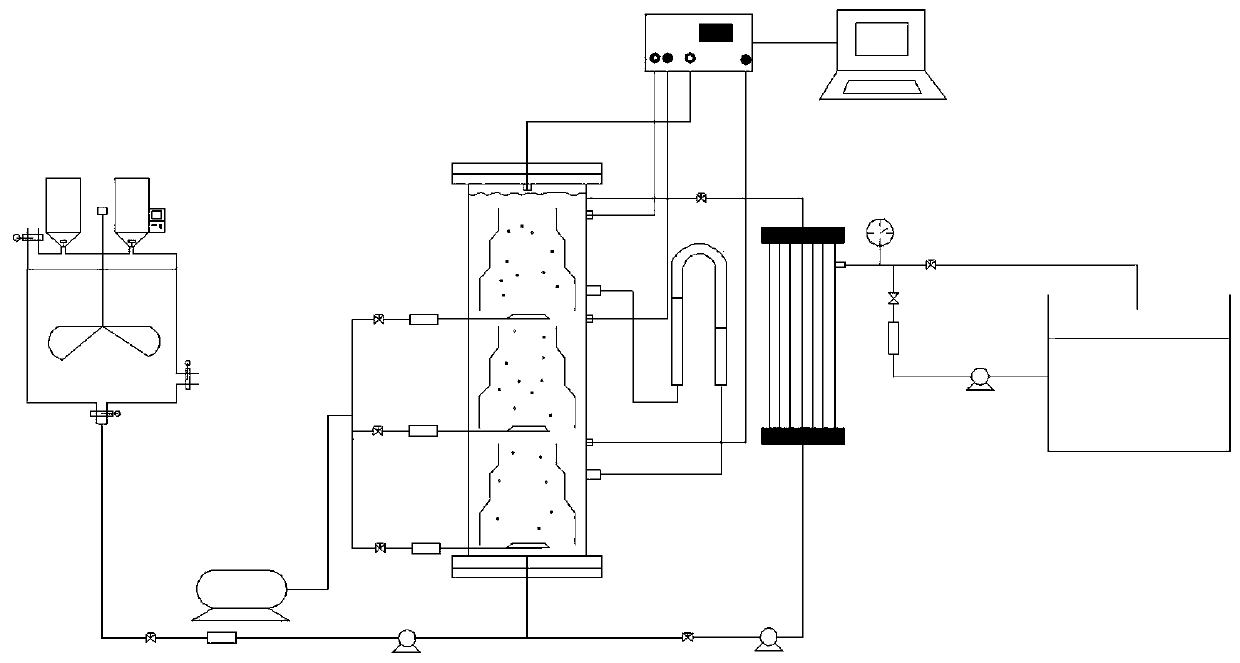

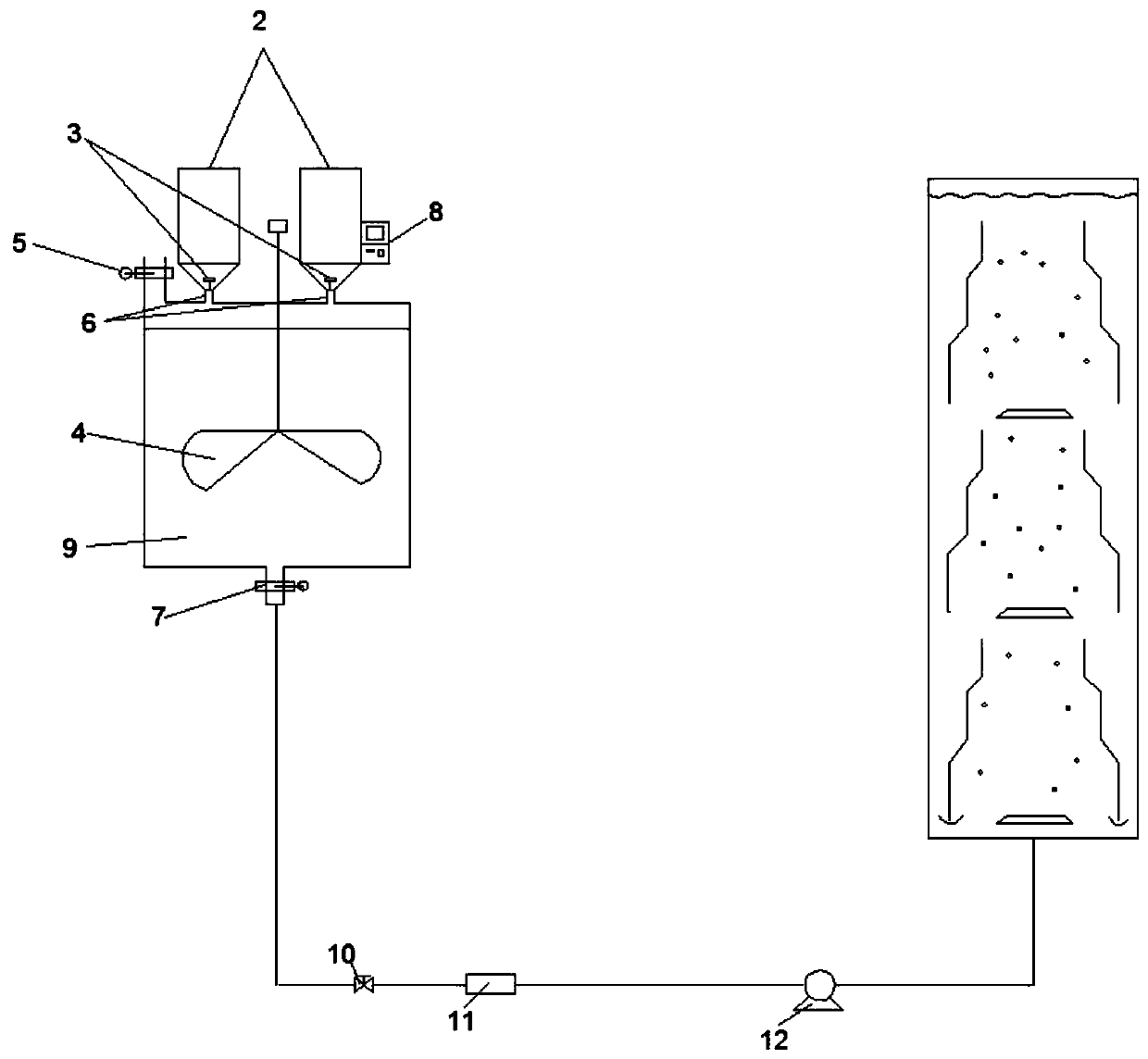

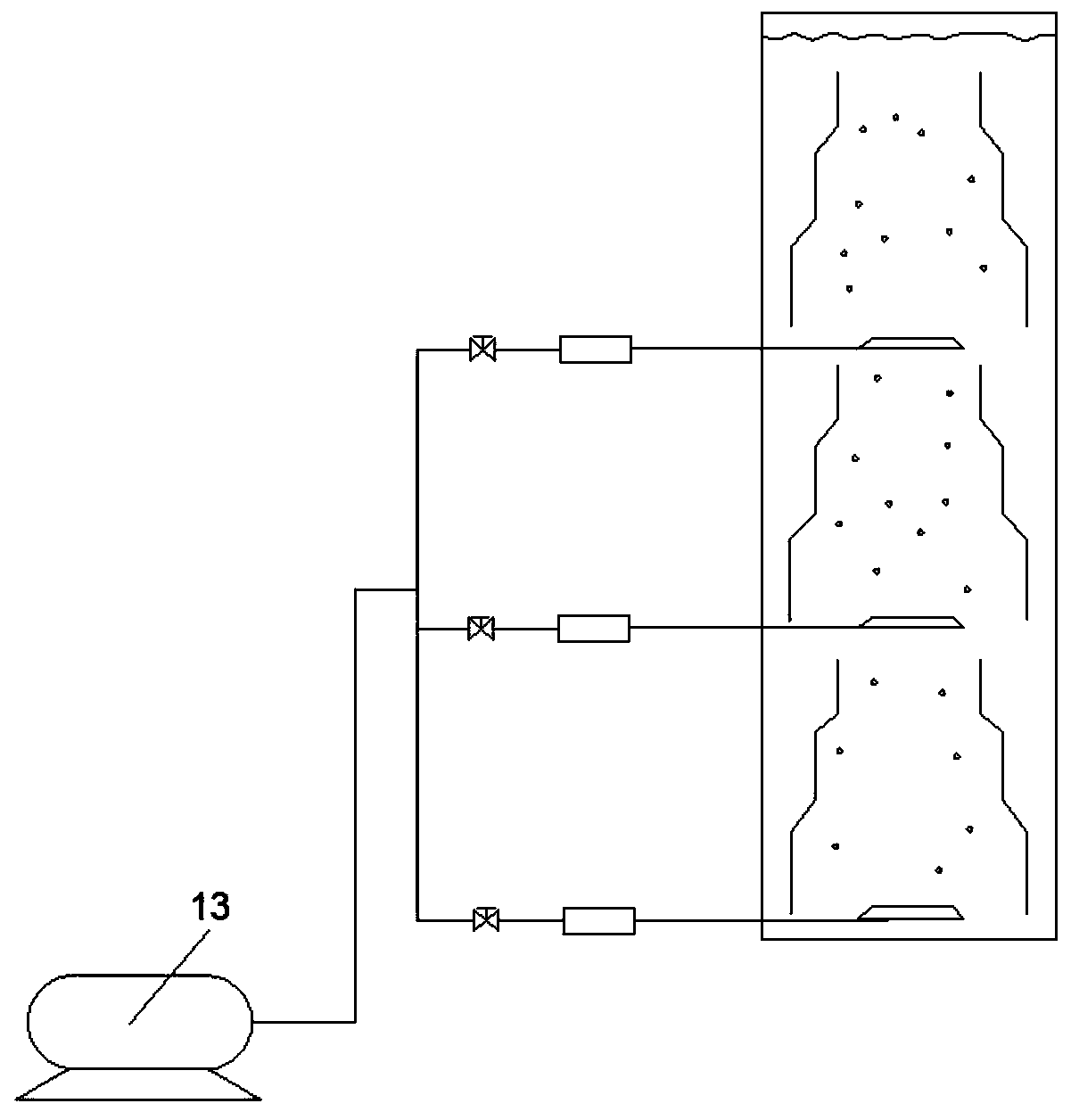

[0021] A multi-section vertical variable-diameter diversion cylinder central airlift loop reactor, including a reaction system; the reaction system includes an outer cylinder 15, a variable-diameter diversion cylinder 14, and an inverted U-shaped tube pressure gauge 17, and the inverted U-shaped tube The two openings of the pressure gauge 17 communicate with the upper opening and the lower opening of the outer cylinder 15 respectively, and the outer cylinder 15 is vertically provided with a plurality of variable-diameter guide tubes 14 through brackets, and the smaller end of the variable-diameter guide tube 14 is Upwards, a microporous plate 16 is provided below the larger end of the variable diameter guide tube 14 opening, the micropore plate 16 is fixed by a bracket, and the bottom of the outer cylinder 15 is provided with a sewage inlet; the preferred variable diameter guide tube 14 and the micropore plate The number of 16 is 3; due to the difference in phase holdup between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com