Disassembly and assembly tool and method for detachable interference-fit anti-rolling torsion bar

An anti-rolling torsion bar and interference fit technology, applied in manufacturing tools, hand-held tools, etc., can solve the problem of poor size detection of the matching area between the torsion arm and the torsion bar shaft, inconvenient maintenance of the anti-rolling torsion bar, and inconvenient replacement of accessories. Convenience and other issues, to achieve the effect of good size detectability, good repairability, and low probability of damage to the joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

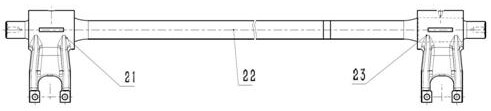

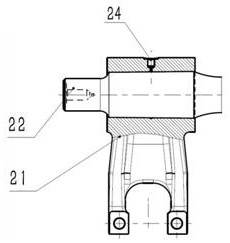

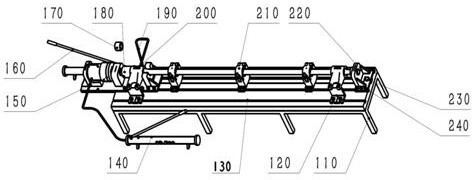

[0064] Please refer to Figure 1 to Figure 10 , a disassembly and assembly tool for detachable interference fit anti-roll torsion bar, used to realize the high-precision assembly and disassembly of the torsion arm and the torsion bar shaft of the cone interference fit anti-roll torsion bar device, and can realize Reliable assembly and disassembly for multiple repetitions. Including bracket 110, height positioning block 120, base plate 130, hydraulic manual pump 140, pressure output assembly 150, ultra-high pressure manual pump 160, torsion bar shaft pressure head assembly 170, torsion arm pressure head assembly 180, high-pressure oil pipe 190, high-pressure oil pump fast Joint 200 , support seat assembly 210 , baffle plate assembly 220 , positioning pin 230 , and T-shaped bolt group 240 . The anti-roll torsion bar (i.e.: used for detachable interference fit anti-roll torsion bar) includes a torsion arm and a torsion bar shaft 22. The torsion arm includes a torsion arm 1 21 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com