Vibratory mud discharging device for potato harvester

A technology of mud discharge device and vibration device, which is applied to digging harvesters, harvesters, applications, etc., can solve problems such as high energy consumption, impact on economic income, and inability to harvest in time, and achieve adjustment, vibration amplitude, and high efficiency The effect of automated harvesting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

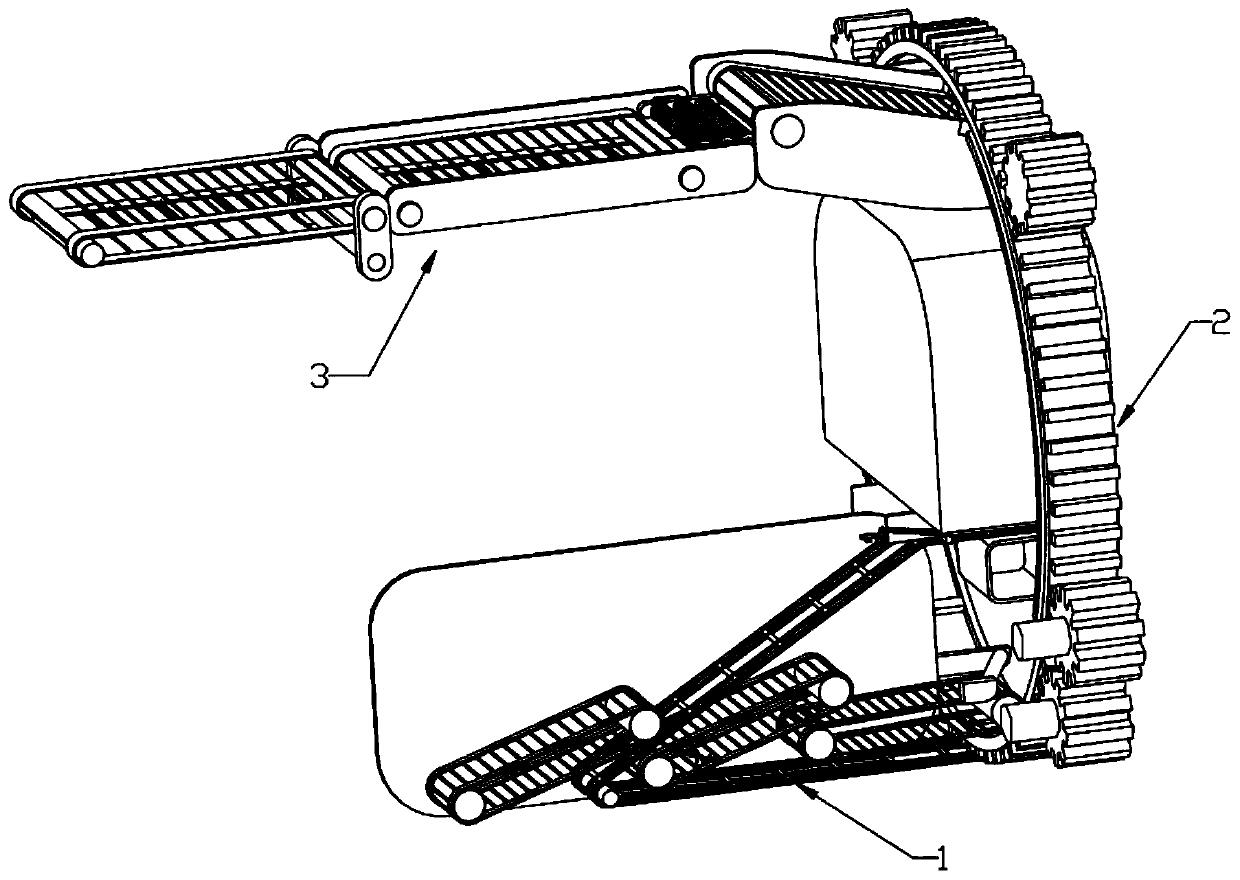

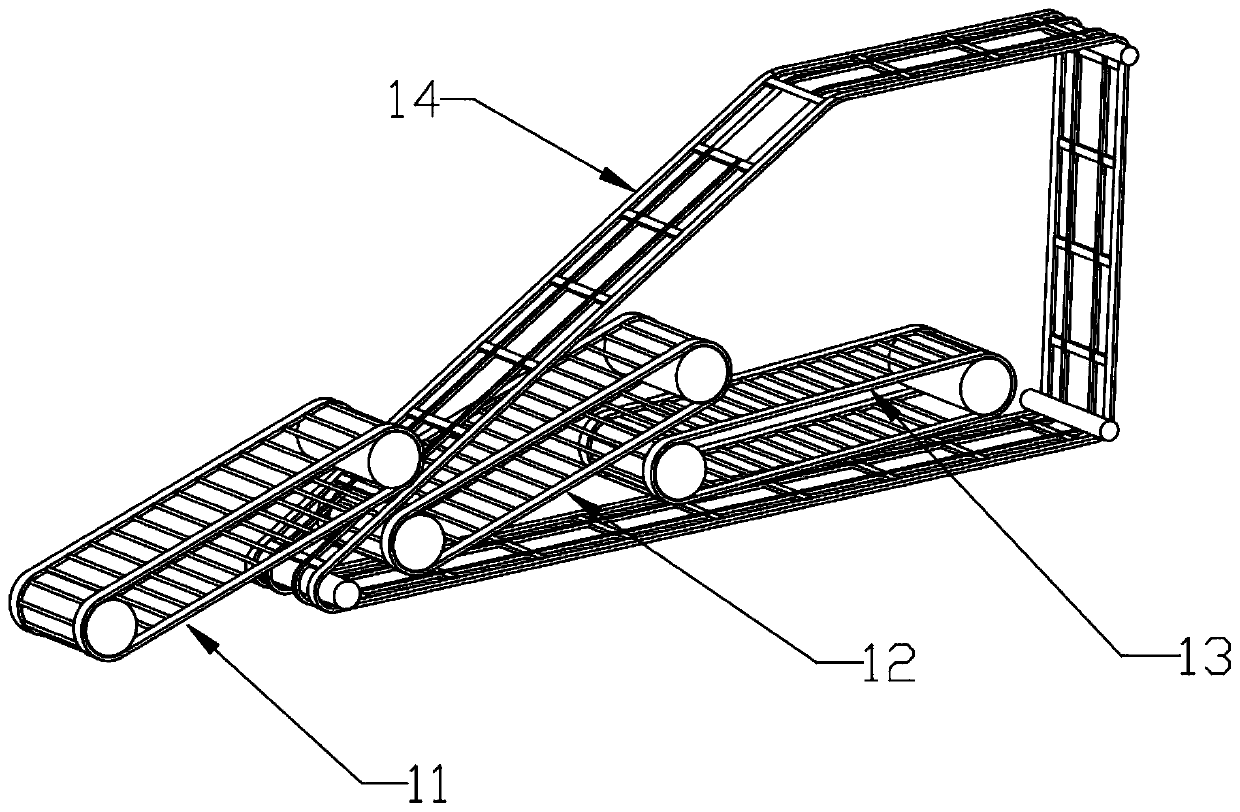

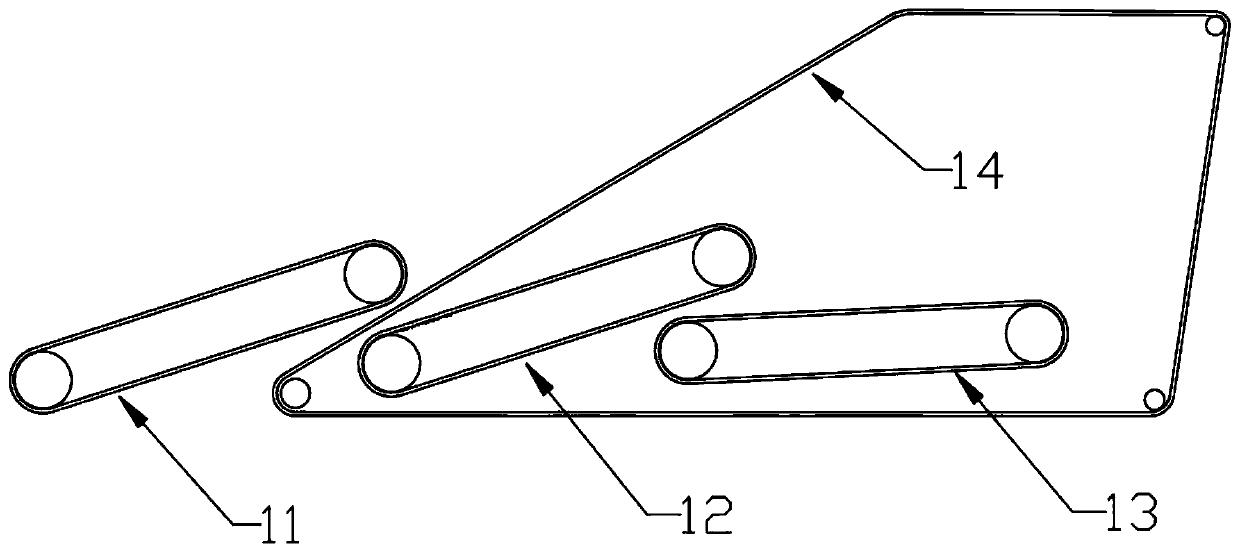

[0027] Such as Figure 1-12 As shown, a material conveying device of a potato harvester includes an excavating and collecting device 1 , a lifting device 2 and a blanking conveying device 3 .

[0028] The excavating and collecting device 1 includes a first conveyor belt 11, a second conveyor belt 12 and a third conveyor belt 13 connected in sequence; Some root rubber damping pipes; Also be provided with stem and leaf separating belt 14 between the first conveyer belt 11 and the second conveyer belt 12, described stem and leaf separating belt 14 is connected with the stem and leaf winding belt that is the well-shaped distribution; The tails of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com