Novel unshaped refractory vibrator

A technology of refractory materials and vibrators, applied in furnaces, lining repairs, lighting and heating equipment, etc., can solve problems such as inability to guarantee construction quality, inconvenient installation and fixation, and inability of the vibration process to fully meet the technical requirements. The pounding effect is good, avoiding the effect of being stuck or missing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

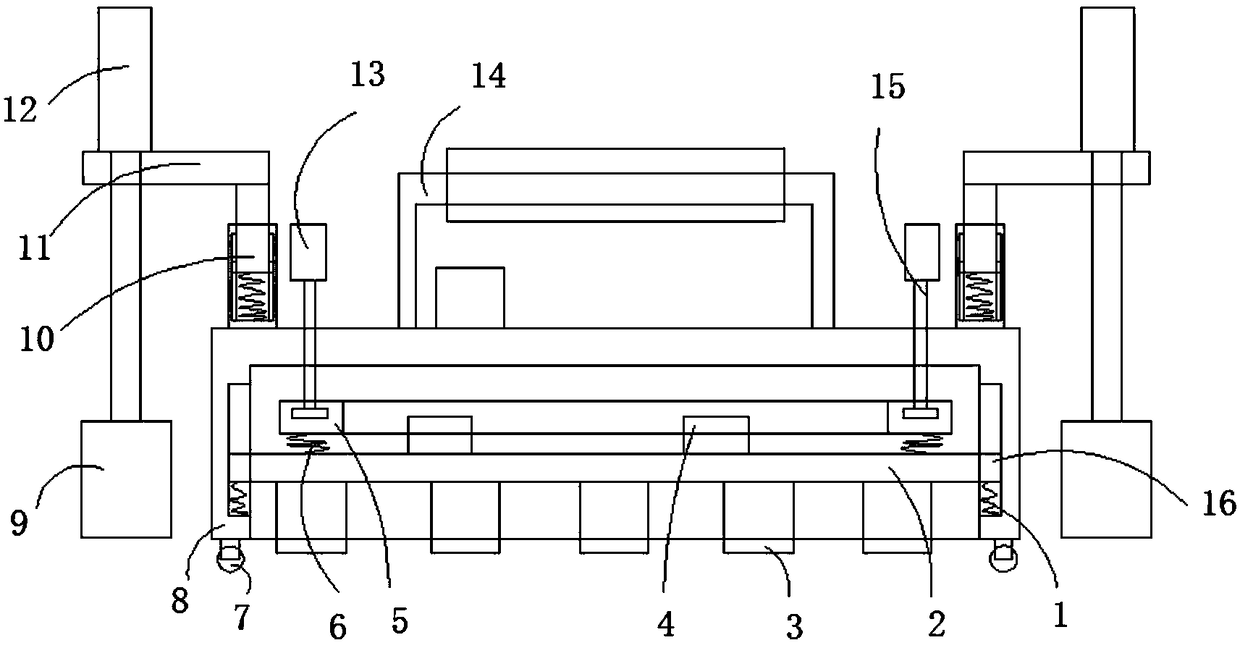

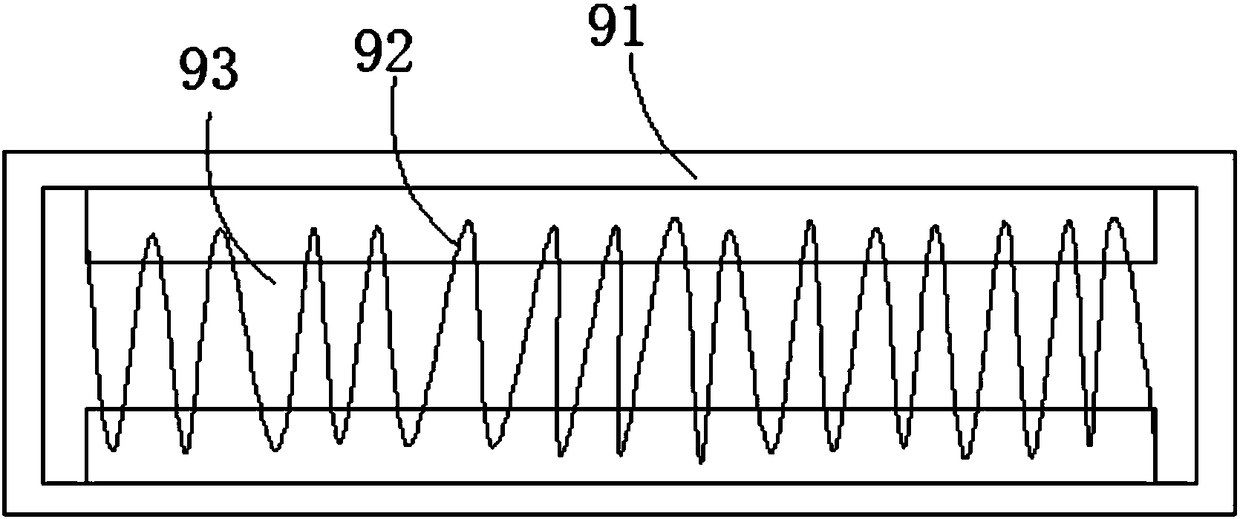

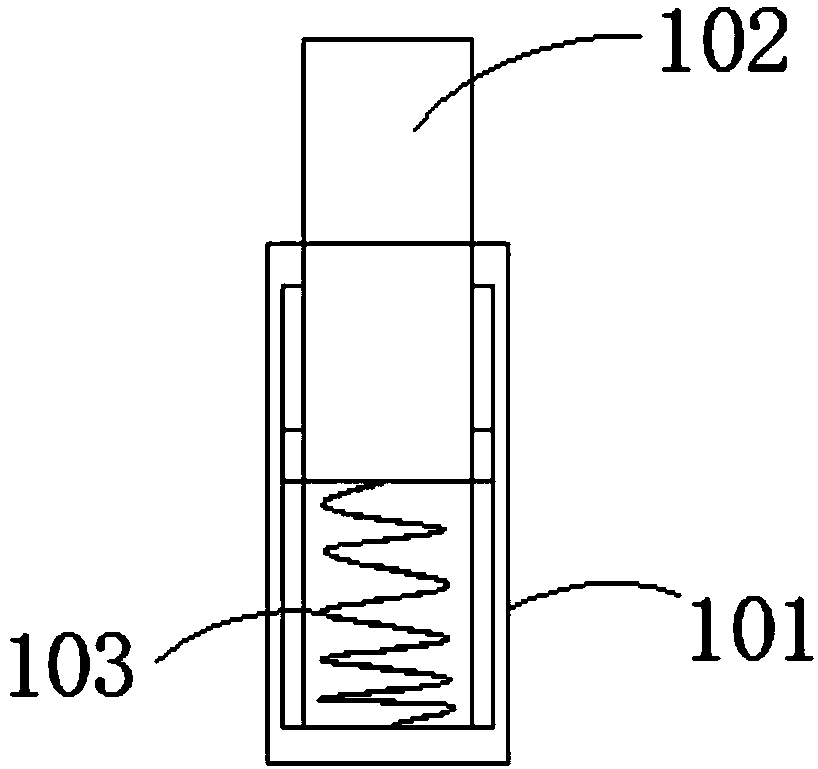

[0021] refer to Figure 1-3 , a new type of unshaped refractory vibrator, including an installation box 8 with an open bottom end, four vertically arranged threaded rods 15 are rotatably connected to the top side wall of the installation box 8, and the bottom end of the threaded rod 15 is rotatably connected to a horizontally arranged The adjustment ring 5 is located inside the installation box 8, and the bottom end of the adjustment ring 5 is connected with a plurality of second springs 6, and the bottom end of the second spring 6 is connected with a vibrating plate body 2 arranged horizontally, and the vibrating plate body A plurality of vibrating motors 4 are inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com