An impact test device and experimental method based on a space-moving sandwich plate structure

A technology of space movement and impact testing, which is applied in the testing of machines/structural components, impact testing, measuring devices, etc., can solve problems such as simulation of impact response behavior tests of composite sandwich panels, and achieve convenient and rapid installation and combination replacement, and realize The effect of synchronicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

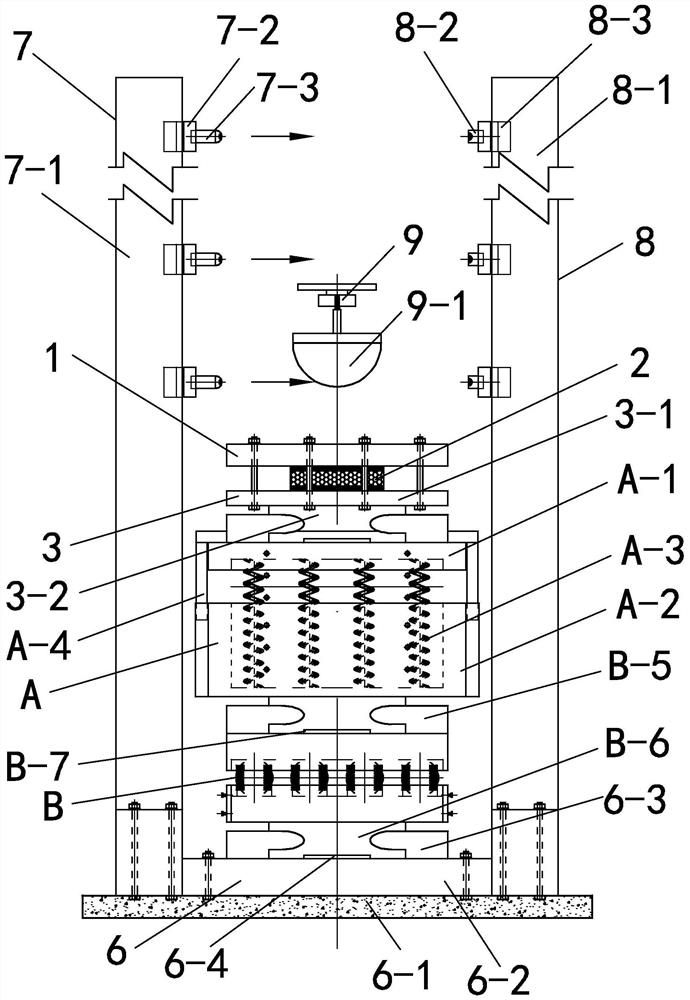

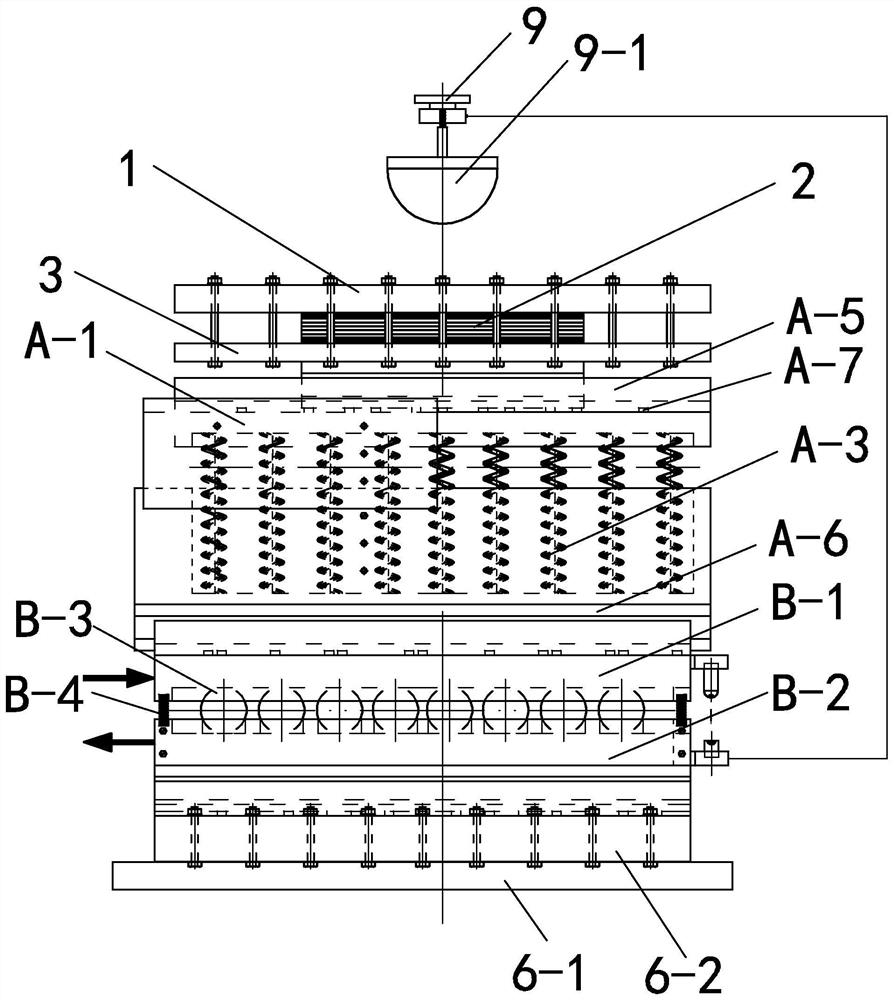

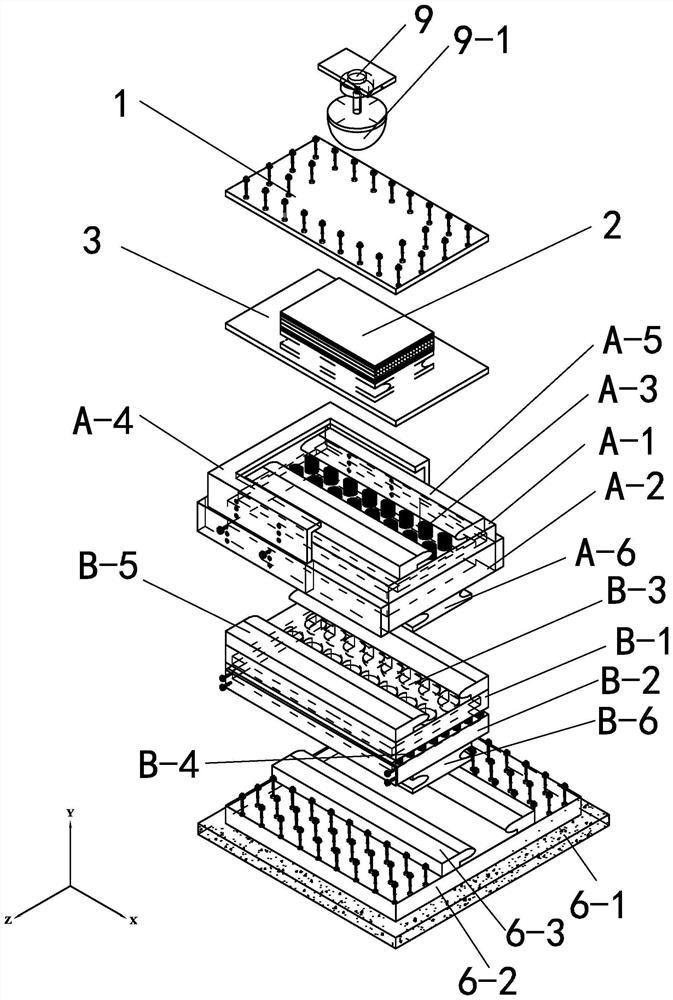

[0033] DETAILED DESCRIPTION One: Combination Figures 1 to 7 In the present embodiment, the impact test apparatus according to the present embodiment includes a spatial motion clipboard structure includes a splint 1, a lower mounting pinch 3, a vertical planar vibration device A, a horizontal planar motion device B, an experimental base 6, a signal The occurrence device 7 and the signal receiving apparatus 8, the signal generating device 7, and the signal receiving device 8 are opposed to the experimental base 6, and the horizontal planar motion device B is inserted on the experimental base 6, and the horizontal plane motion device B is located Between the signal generating device 7 and the signal receiving device 8, the vertical planar vibration device A is inserted on the horizontal planar motion device B, and the upper mounting splint 1 and the lower mounting splint 3 are buckled and the composite clamp plate 2 is sandwiched and the mounting splint 3 is mounted 3. The impact sig...

specific Embodiment approach 2

[0041] DETAILED DESCRIPTION 2: Combination Figure 1 to 3 In this embodiment, the lower mounting pinch 3 of the present embodiment includes a lower pinch plate 3-1 and a clamp slide 3-2, and the clamp slide 3-2 is fixedly mounted on the lower end surface of the lower pinch plate 3-1. As such, it is convenient to cooperate with the vertical plane vibration device A and slide. Other components and connection relationships are the same as those of the specific embodiments.

specific Embodiment approach 3

[0042] Detailed Embodiment 3: Combination Figure 1 to 3 In the present embodiment, the vertical planar vibration device A of the present embodiment includes an upper connection cover plate A-1, a lower connection cover plate A-2, a limiter A-4, and a plurality of vibration springs A-3, and a lower connection cover plate. The groove is opened in the A-2, and the plurality of vibrating springs A-3 are mounted inside the cover plate A-2, and the upper attached cover plate A-1 is attached to the plurality of vibrating springs A-3, and the cover plate A- 1 and the lower connection cover plate A-2 are connected by the limiter A-4, and the upper connection cover plate A-1 is located within the limiter A-4 and can be floated up and down under the action of the vibrating spring A-3. This is set, which is convenient for vibration in the vertical direction. Other components and connection relationships are the same as those of the specific embodiments.

[0043] The setting of the limiter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com