Semiconductor device and operation method thereof

A semiconductor and equipment technology, applied in the field of semiconductor integrated circuit manufacturing, can solve the problems of increasing the risk of particle pollution, the risk of wafer falling and fragmentation, reducing the efficiency of wafer processing, and affecting product yield, so as to avoid particle pollution and the risk of fragmentation, The effect of reducing the wafer transfer process and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

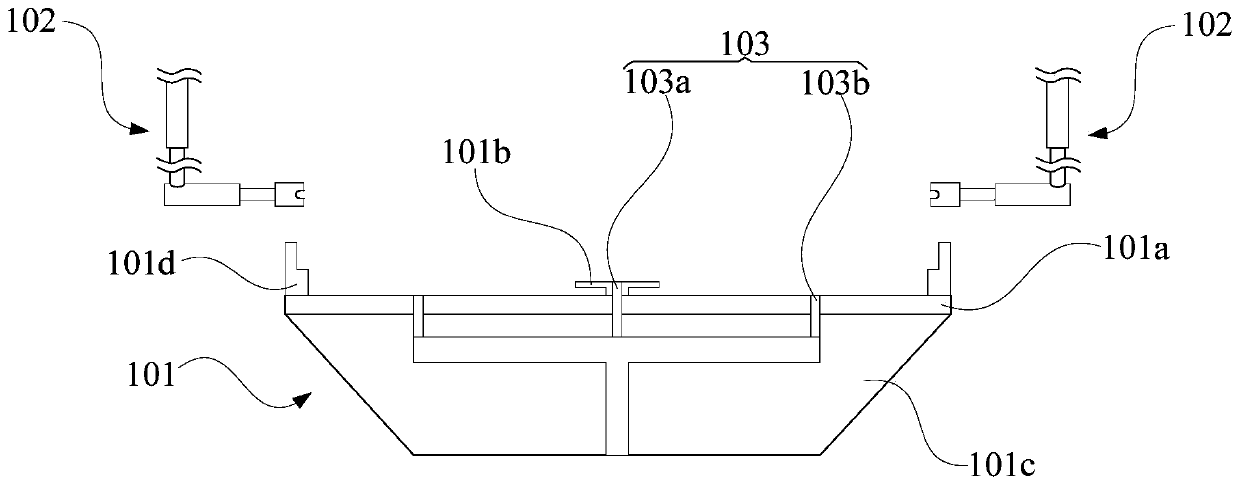

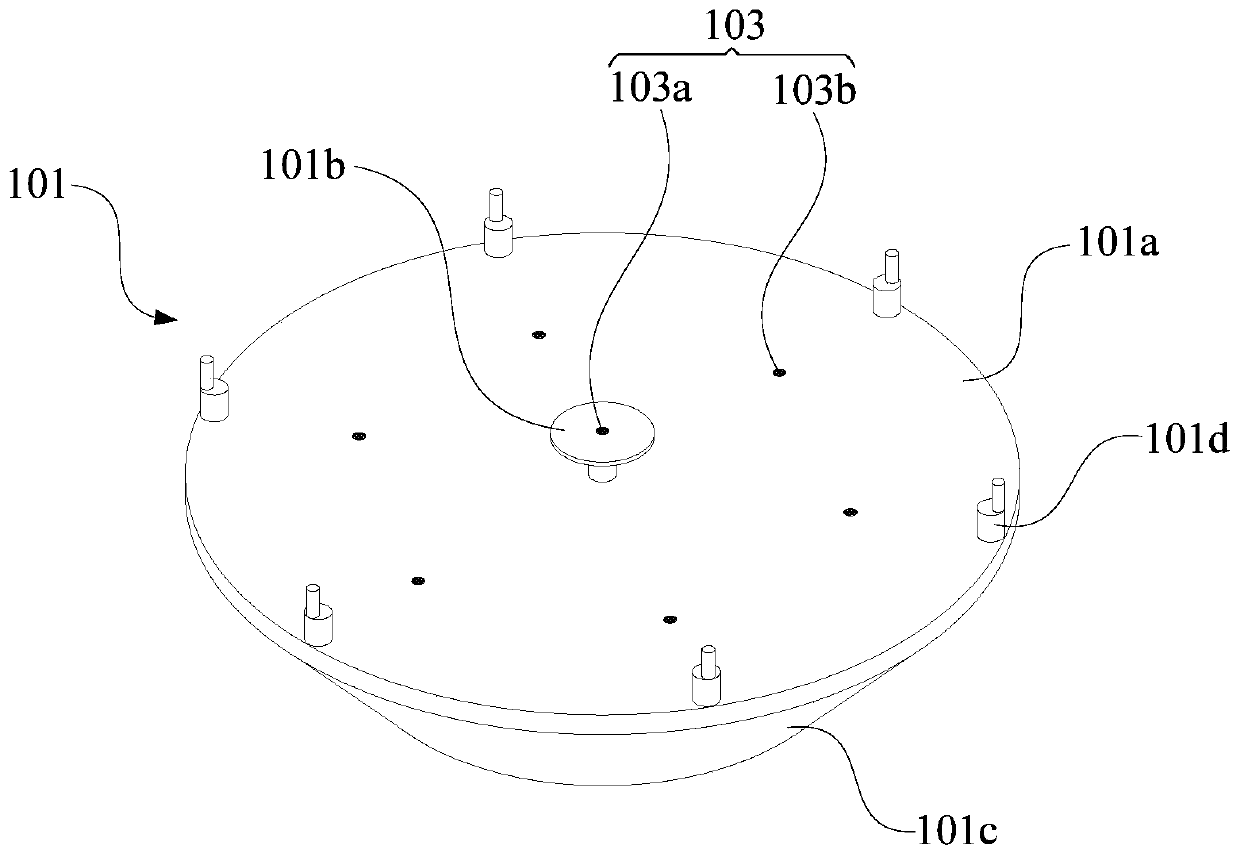

[0052] see Figures 1 to 5 , this embodiment provides a semiconductor device, including:

[0053] The wafer fixing platform 101 is used to fix the wafer during the process; the wafer fixing platform 101 is provided with a wafer placement position for accommodating the wafer at a specified position in a specified plane;

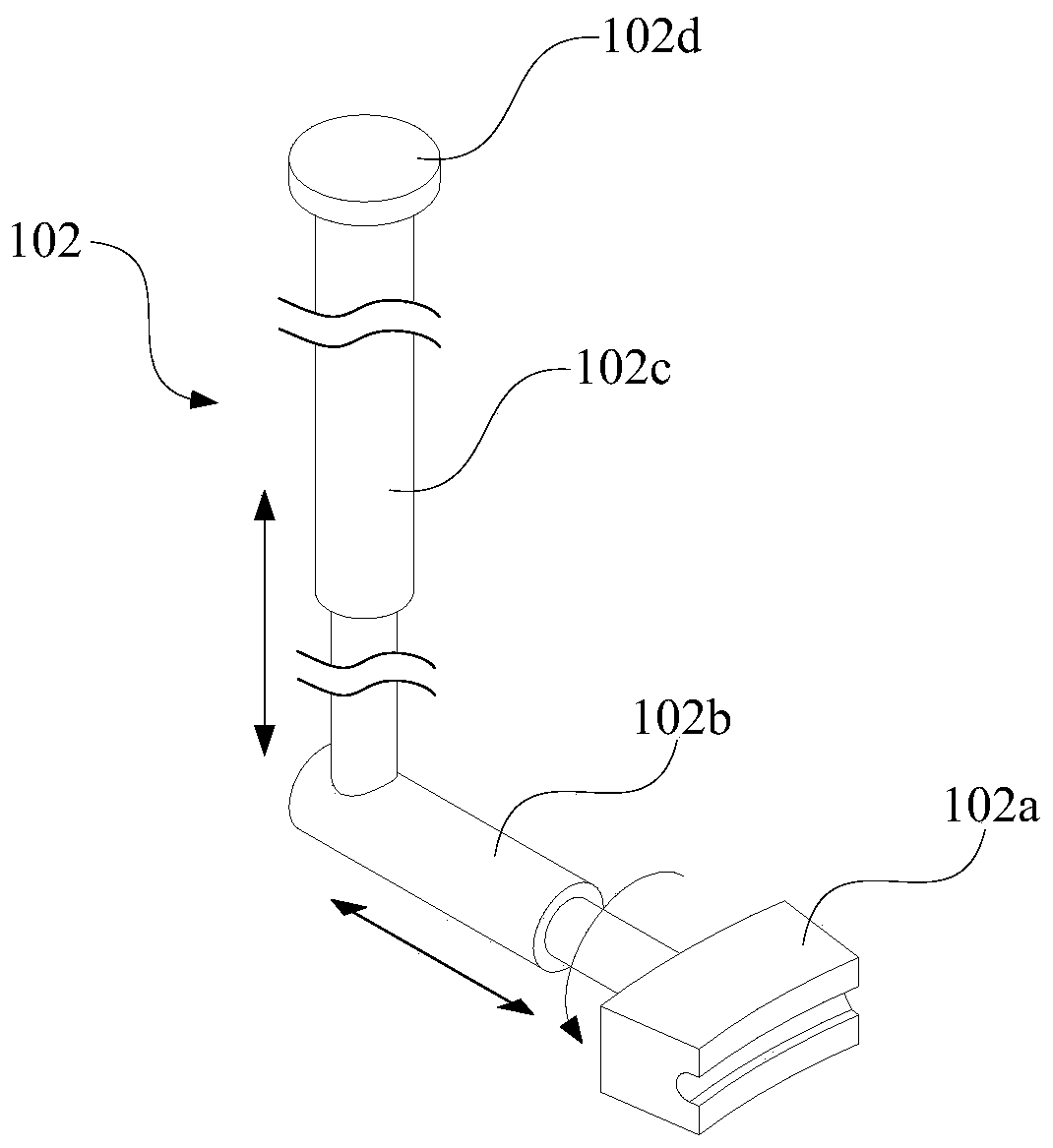

[0054] The wafer inverting device 102 is configured to invert the wafer relative to the specified plane.

[0055] Such as figure 1 Shown is a schematic cross-sectional view of the semiconductor device provided by this embodiment. Optionally, in this embodiment, the semiconductor equipment is a wet equipment used in a wafer wet process. exist figure 1Among them, the wafer fixing platform 101 is used to fix the wafer on the wafer placement position during the wet process, and the pair of wafer turning devices 102 are arranged on the wafer fixing platform 101 above. It should be pointed out that the semiconductor equipment is not limited to wet equipment, a...

Embodiment 2

[0063] see Figure 6 to Figure 12 , the present embodiment provides a method for operating a semiconductor device, comprising the following steps:

[0064] 1) Provide the semiconductor device as described in Embodiment 1 and the wafer 100 having opposite first surface and second surface;

[0065] 2) fixing the wafer 100 on the wafer placement position through the wafer fixing platform 101, the first surface and the second surface of the wafer 100 are respectively parallel to the designated plane;

[0066] 3) Flip the wafer 100 relative to the specified plane by the wafer inversion device 102, so that the first surface and the second surface of the wafer 100 are respectively parallel to the specified plane, and the The first surface faces the direction that the second surface before turning over faces, and the second surface faces the direction that the first surface before turning over faces.

[0067] In step 1), see Figure 6 S1 and figure 1 and Figure 7 , providing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com