A protection device for a vacuum measuring tool of an ion beam etching system

A technology of ion beam etching and vacuum measurement, applied in circuits, discharge tubes, electrical components, etc., can solve problems such as high cost consumption, damage to measurement circuits, and inability to use, and achieve the effect of easy disassembly, cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

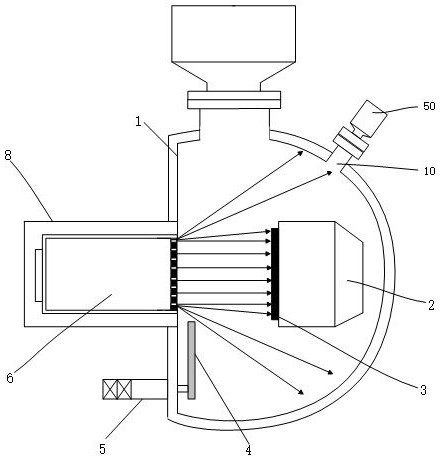

[0024] The ion beam etching system of the present invention such as figure 1 As shown, it includes a reaction chamber 1 , a rotatable etching stage 2 located in the reaction chamber 1 , a rotatable baffle 4 located in the reaction chamber 1 and an ion source 6 capable of generating ion beams.

[0025] The reaction chamber 1 is a hollow chamber with an irregular shape, and an outer sleeve 8 protruding from the chamber is arranged on one side, and an ion source 6 is installed inside the outer sleeve 8 , and the ion source 6 diverges ion beams into the reaction chamber 1 . The wafer 3 to be processed is placed on the etching stage 2 , and the ion beam emitted by the ion source 6 etches the wafer 3 . The baffle 4 is located inside the reaction chamber 1, and its position can be adjusted under the action of a driving device 5 such as a motor or a cylinder. Before the wafer 3 on the etching stage 2 reaches the set position, the baffle 4 is blocked between the ion source 6 and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com