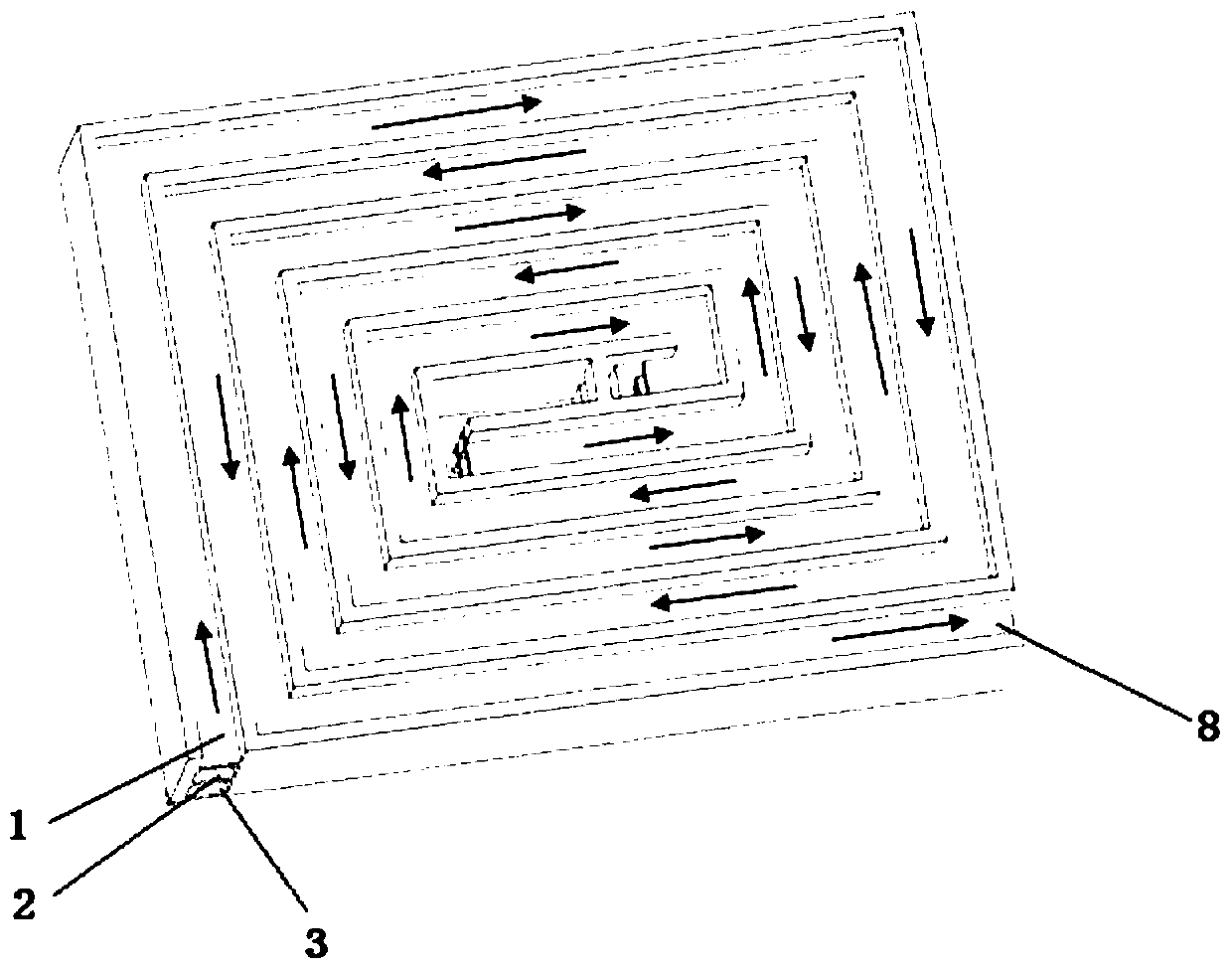

A Small Diffusion Burner with Multi-channel and Efficient Preheating

A diffusion combustion and multi-channel technology, applied in the direction of burners, gas fuel burners, combustion types, etc., can solve the problems of easy tempering and insufficient mixing, so as to prevent tempering, good mixing effect and energy utilization high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Methane gas is used as fuel, and air is used as oxidant. The width and the height of the fuel channel are 3mm, and the distance between the gas outlet and the central baffle is 1mm; The width and height of each flue gas channel are both 3mm. The central baffle is rectangular, and its length, width, and height are 1mm, 3mm, and 5mm respectively; the distance between the central baffle and the wall baffle is 2mm; the length, width, and height of the two wall baffles are 1mm, 3mm and 4mm; the length, width and height of the combustion chamber are 13mm, 3mm and 11mm respectively. The total length, width and height of the burner are 58mm, 45mm and 13mm respectively. The center baffle and the wall baffle are rectangular parallelepiped, and the surface and the inner surface of the combustion chamber are all coated with nickel catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com