Maritime work equipment

A technology for equipment and structural panels, applied in the field of marine engineering equipment, can solve the problems of reduced strength of structural panels, damage of structural panels, no reinforcement measures, etc., and achieves the effect of reducing the probability of being damaged, enhancing the strength, and achieving remarkable effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

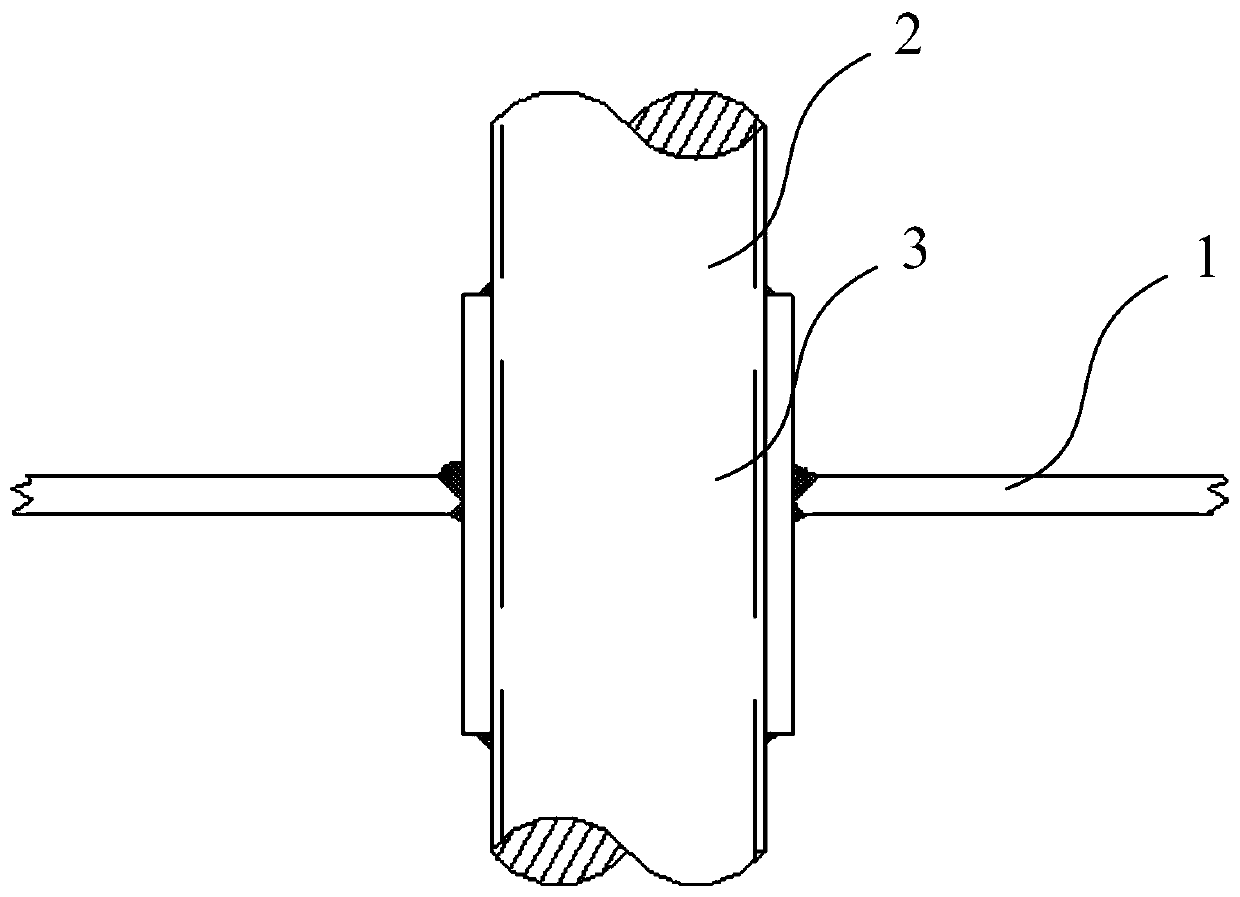

[0049] like Figure 1-2 As shown, this embodiment is a kind of marine engineering equipment. The marine engineering equipment includes a structural plate 1, a casing 2 and a reinforcing piece. Both the structural plate 1 and the reinforcing piece are provided with through holes. The through hole of 1 is reinforced, the sleeve 2 passes through the through hole, the sleeve 2 is connected with the structural plate 1 through the reinforcement, and the reinforcement is connected with the structural plate 1 and the sleeve 2 by welding. In this embodiment, a reinforcing piece is provided between the casing 2 and the structural plate 1, and at the same time, the components are connected by welding, so as to achieve the purpose of strengthening the strength of the opening of the structural plate 1, and can reduce the structure of the opening area. Probability that plate 1 is destroyed. At the same time, since the reinforcing piece is also welded to the casing 2 , it also plays a role ...

Embodiment 2

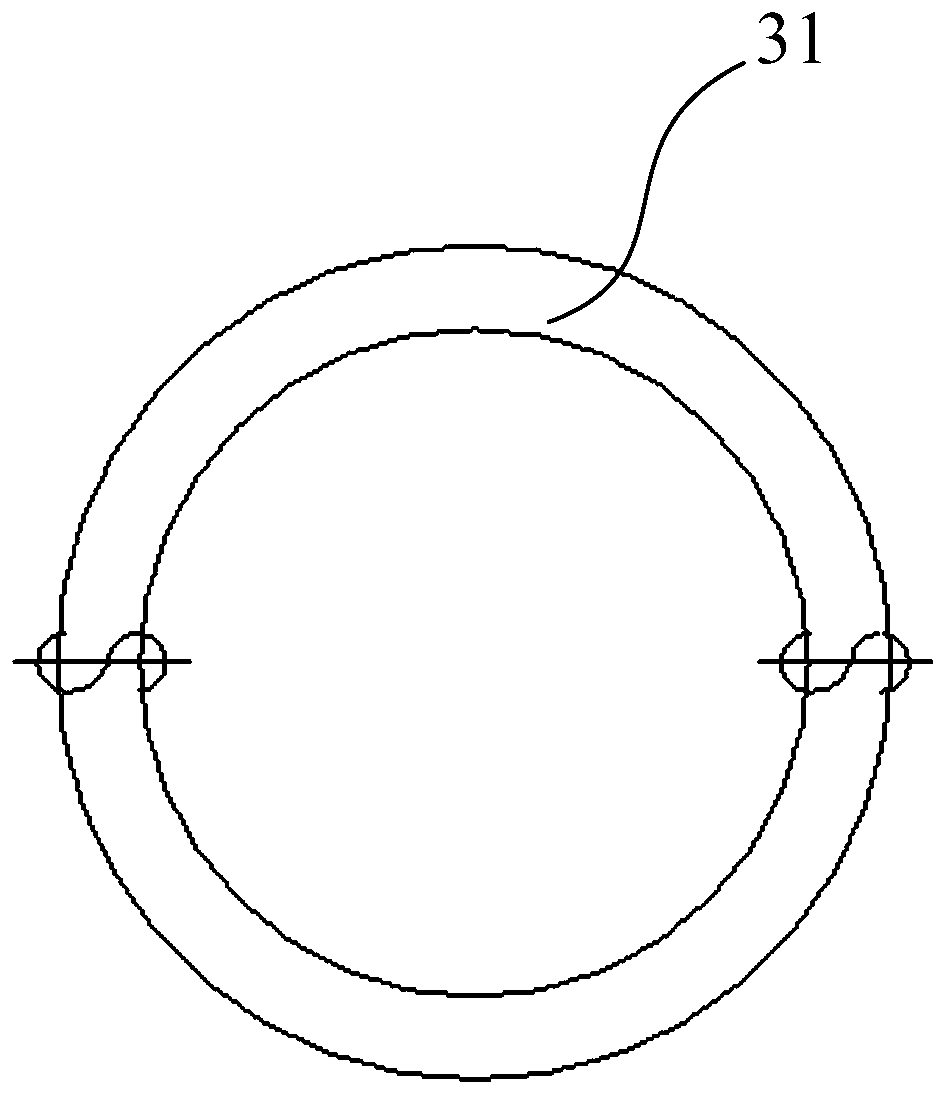

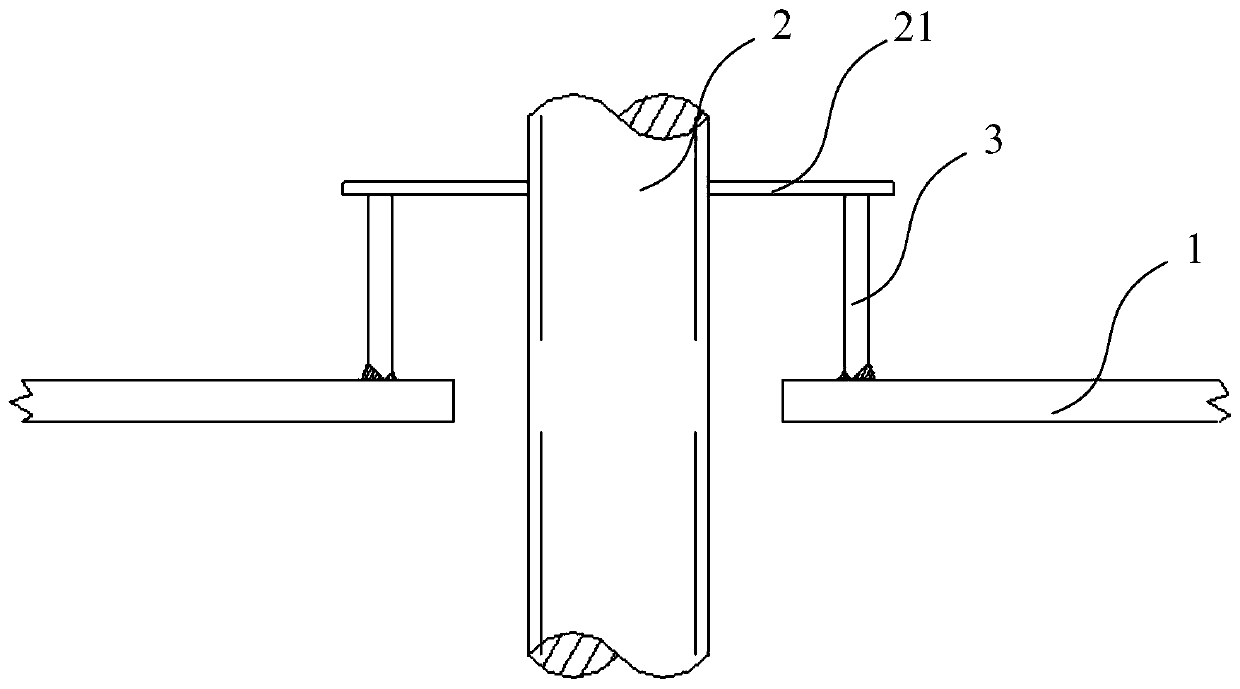

[0057] like Figure 3-5 As shown, this embodiment is basically the same as Embodiment 1, the difference is that: the round tube 3 is installed on the side of the structural plate 1, and the casing 2 also includes an attached plate 21, the casing 2 passes through the attached plate 21, and the attached plate 21 is connected with one end of round pipe 3. In this embodiment, the attached plate 21 is connected with the round pipe 3, which improves the toughness of the casing 2. When the stress is too large, the attached plate 21 will be damaged first, thereby protecting the structural plate 1 and avoiding the structural plate 1. directly destroyed.

[0058] In this embodiment, the other end of the circular tube 3 is connected to the side of the structural plate 1 . In this embodiment, the round pipe 3 is arranged on the side of the structural plate 1, which is beneficial to simplify the installation process of the round pipe 3 and reduce the installation man-hour.

[0059] As a...

Embodiment 3

[0062] like Figure 6 As shown, this embodiment is basically the same as Embodiment 1, except that the different dimensions lie in that: the collective reinforcing part of this embodiment is designed as a reinforcing plate 4 . The reinforcing plate 4 is welded to the side of the structural plate 1 . In this embodiment, the strength of the structural plate 1 is improved by welding the reinforcing plate 4 to the side of the structural plate 1 . In other embodiments, the material of the reinforcing plate 4 can also be the same as that of the structural plate 1, and the material of the reinforcing plate 4 is designed to be the same material as the structural plate 1, which is beneficial to improve the unity of the components after welding. The thickness of the reinforcing plate 4 can also be designed to be the same as the thickness of the structural plate 1 or 50%-95% of the thickness of the structural plate 1 . This embodiment is conducive to fully improving the strength of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com