Washing machine

A technology of washing machine and inner cylinder, which is applied in the field of washing machines, can solve the problems of increased bacteria in washing machines, inability to clean, and low utilization rate of the inner space of washing machines, and achieve the effects of avoiding incomplete washing of clothes, improving washing cleanliness, and being suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

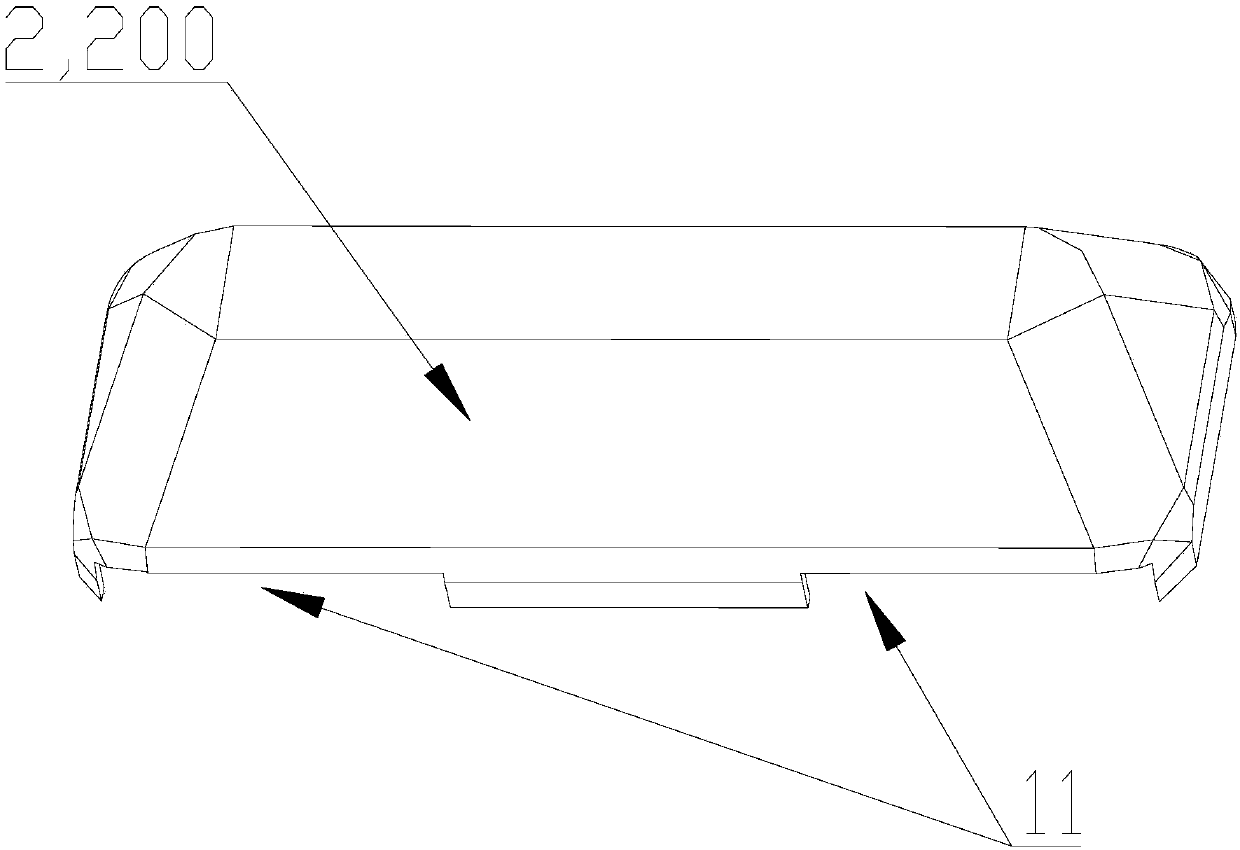

Image

Examples

Embodiment 1

[0048] Such as Figure 8 with Figure 12 As shown, in the embodiment of the present invention, in order to seal and fasten the inner cylinder opening 101 of the washing machine, prevent the washing water from flowing out from the inner cylinder opening, and realize the inner cylinder 1 sealing water for normal washing during the working process of the washing machine, the following settings are performed:

[0049] In this embodiment, a washing machine is introduced. An inner cylinder cover 700 that can be opened and closed to close the opening is provided at the mouth 101 of the inner cylinder of the washing machine, so that the inner cylinder can form an airtight container after the inner cylinder cover 700 is correspondingly fastened to the inner cylinder mouth 101.

[0050] By setting the inner cylinder cover at the mouth of the inner cylinder, the inner cylinder can form a sealed container for washing after the inner cylinder cover is correspondingly fastened to the cylind...

Embodiment 2

[0060] In this embodiment, in order to allow water to enter the inner cylinder of the washing machine and to realize normal washing of the inner cylinder sealed with water during the working process of the washing machine, the following settings are made:

[0061] Such as Figure 8 with Figure 9 As shown, this embodiment introduces a washing machine water inlet structure. The washing machine housing 100 is provided with an inner cylinder 1. The rear part of the inner cylinder 1 is an inner cylinder bottom 102, and the center of the inner cylinder bottom 102 extends axially backward. The rotating shaft of the rotating shaft is connected with the inner cylinder support member 300; the center of the inner cylinder bottom 102 is connected with one end of the water inlet pipe 900, and the water inlet pipe 900 passes through the rotating shaft and extends upward to communicate with the water inlet box of the washing machine. The water inlet pipe 900 is provided with a control The ...

Embodiment 3

[0066] In the embodiment of the present invention, in order to discharge the water in the inner cylinder of the washing machine, and realize the sealing of the inner cylinder to hold water for normal washing during the working process of the washing machine, the following settings are made:

[0067] Such as Figure 8 to Figure 11 As shown, a drainage structure of a washing machine, an inner cylinder 1 is installed in the washing machine housing 100, a drain outlet 230 is provided on the inner cylinder 1, and a drain valve 240 in a normally closed state is installed at the drain outlet 230; Rotate the inner cylinder 1 to a fixed drainage position and fix the positioning locking mechanism; the washing machine is equipped with a spool opening mechanism that opens the drain valve 240 after the inner cylinder 1 is rotated to a fixed drainage position, so that when the washing machine is in the drainage state, the inner cylinder 1 After rotating to the fixed drain position, open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com