Vertical centrifugal separation discharge grinding system

A vertical centrifugation and separation technology, applied in grain processing and other directions, can solve the problems of difficult cleaning, easy blockage of the discharge screen, small flow rate, etc., and achieves the effect of ingenious design, simple structure, and easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

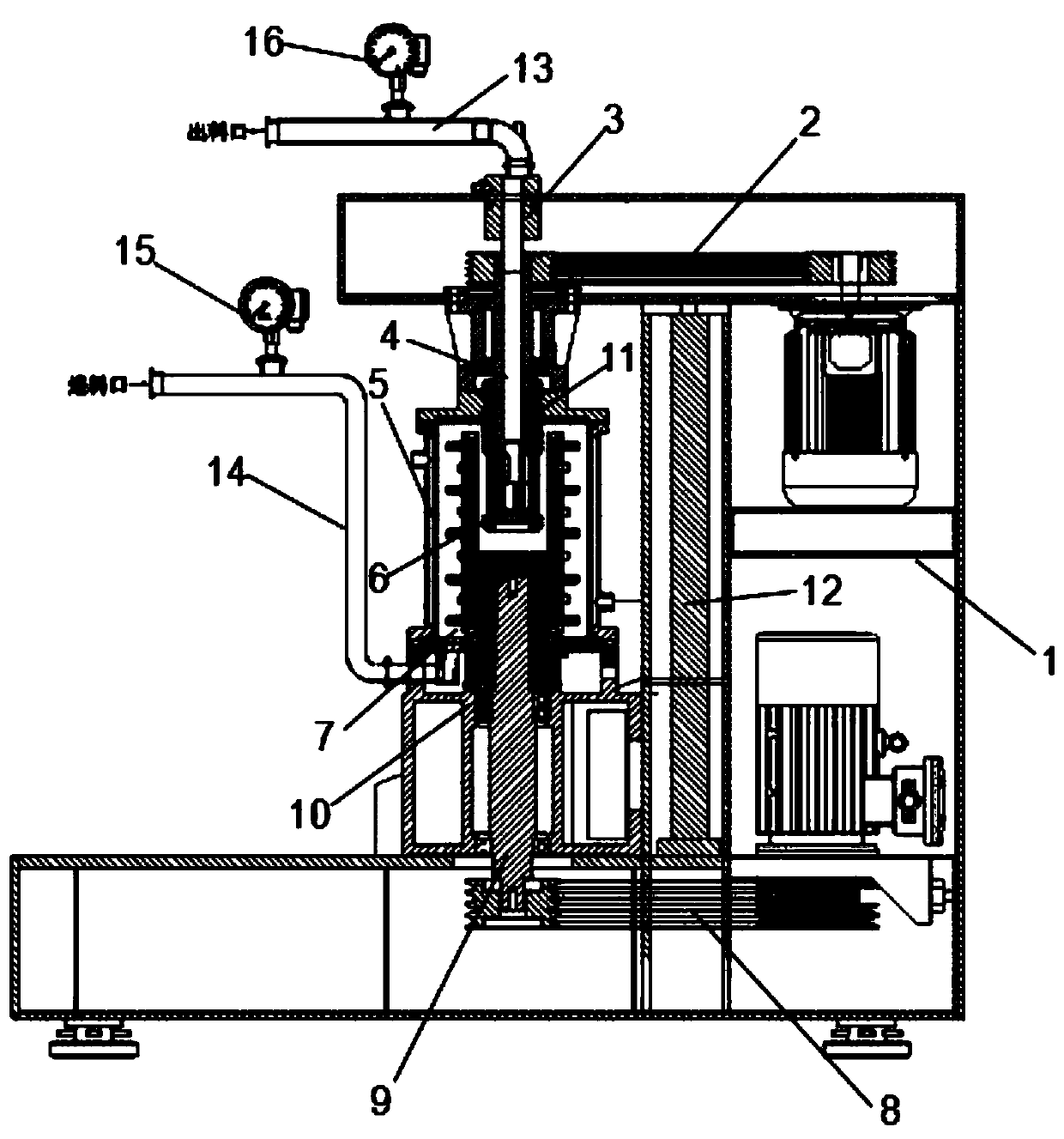

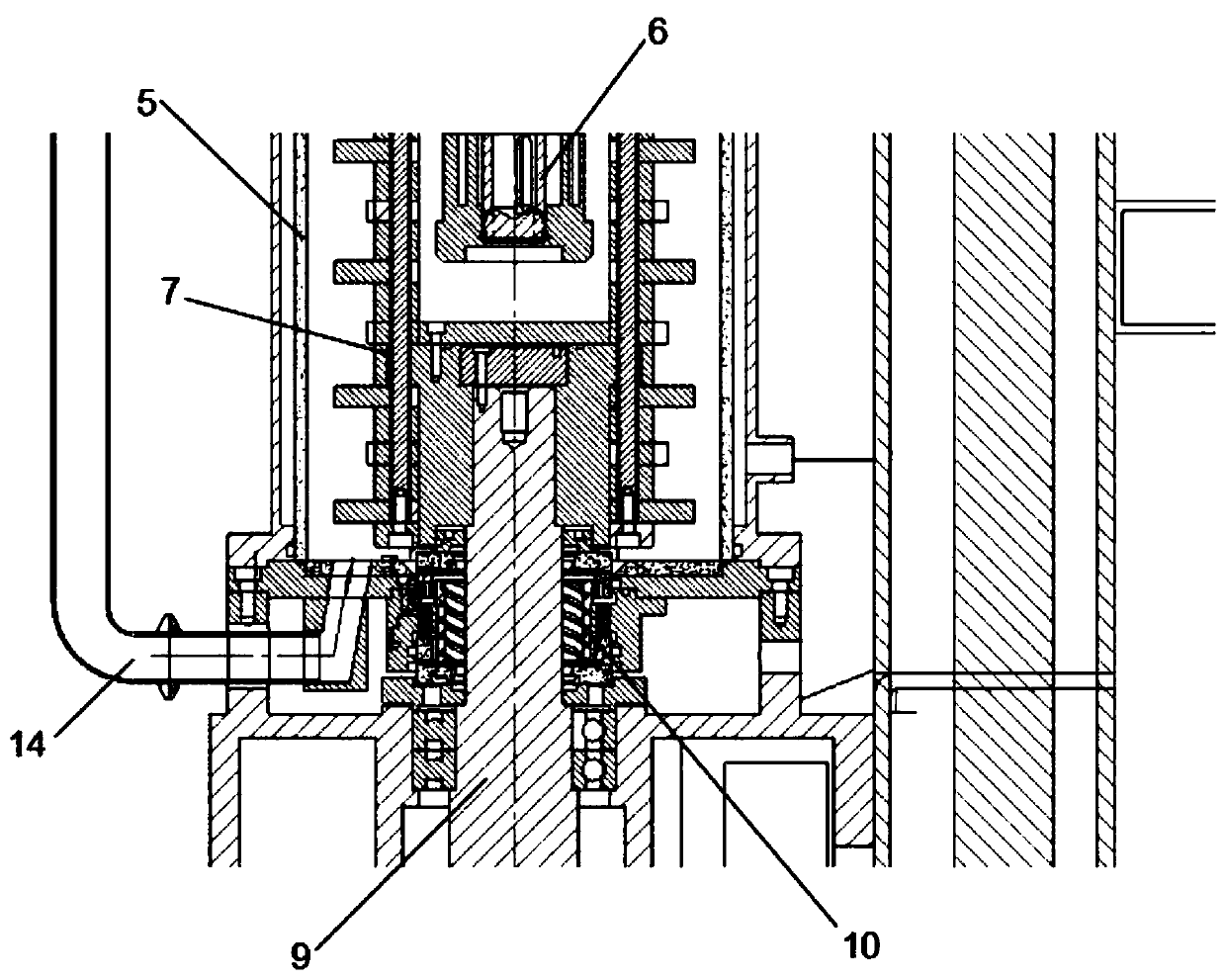

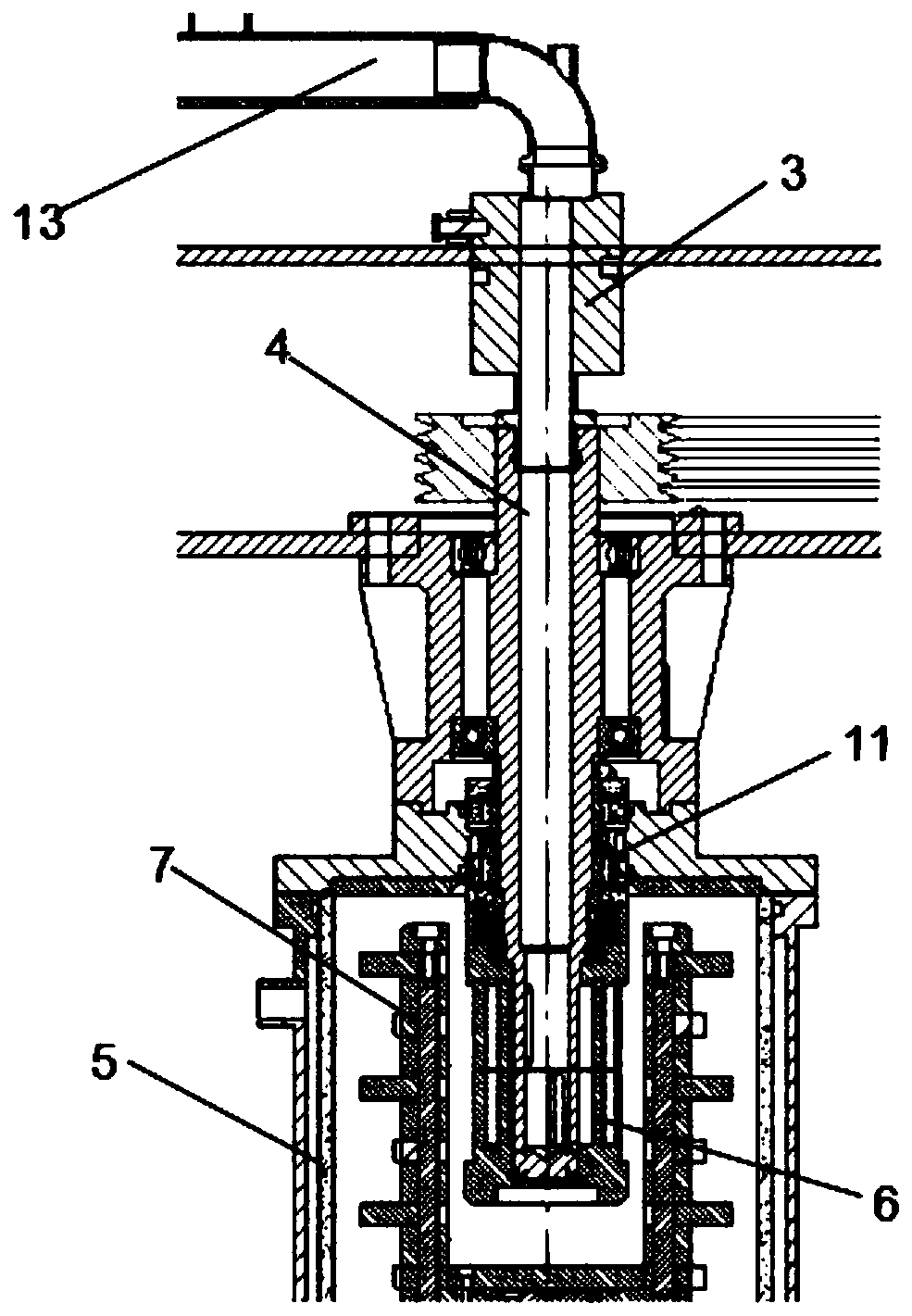

[0018] Embodiment 1: A kind of vertical centrifugal separation discharge grinding system.

[0019] refer to Figure 1 to Figure 3 Shown, a kind of vertical centrifugal separation discharging grinding system comprises:

[0020] Frame 1, the frame 1 is welded by steel plates or iron plates, and is used to provide installation or support positions for other components;

[0021] The grinding chamber 5 fixed on the frame 1 and placed vertically, the grinding chamber 5 is provided with a cavity inside, which is the carrier of the material and the grinding medium;

[0022] The first rotating shaft 4 installed vertically downward on the top beam of the frame 1, the first rotating shaft 4 runs through the top of the grinding chamber 5 and extends into the grinding chamber 5, the first rotating shaft 4 and the grinding chamber 5 A first mechanical seal 11 is provided at the top penetration to ensure no liquid leakage at the top penetration of the first rotating shaft 4 and the grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com