Full-automatic running-in detection system and method for rail transit cylinder

A detection system and rail transit technology, applied in the direction of measuring the rate of increase and deceleration of fluid, using liquid/vacuum degree for liquid tightness measurement, railway vehicle testing, etc., can solve the problems of low efficiency, inaccurate detection, time-consuming and laborious, etc. , to improve test efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

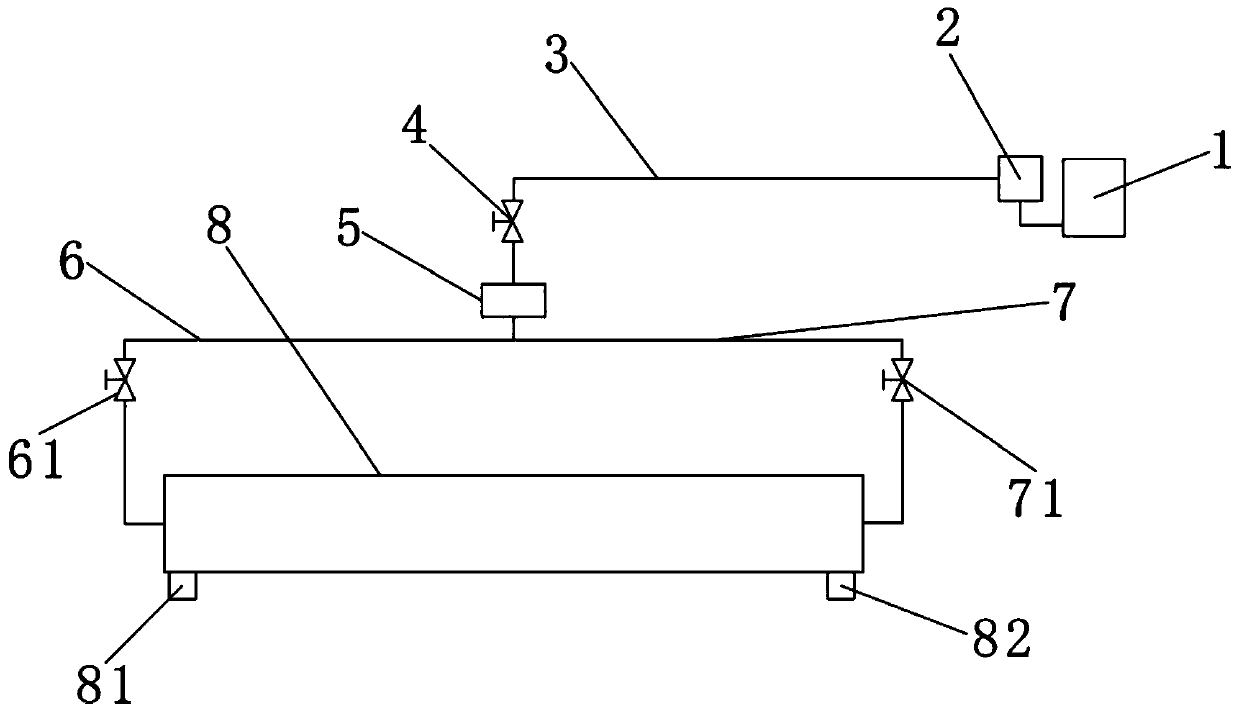

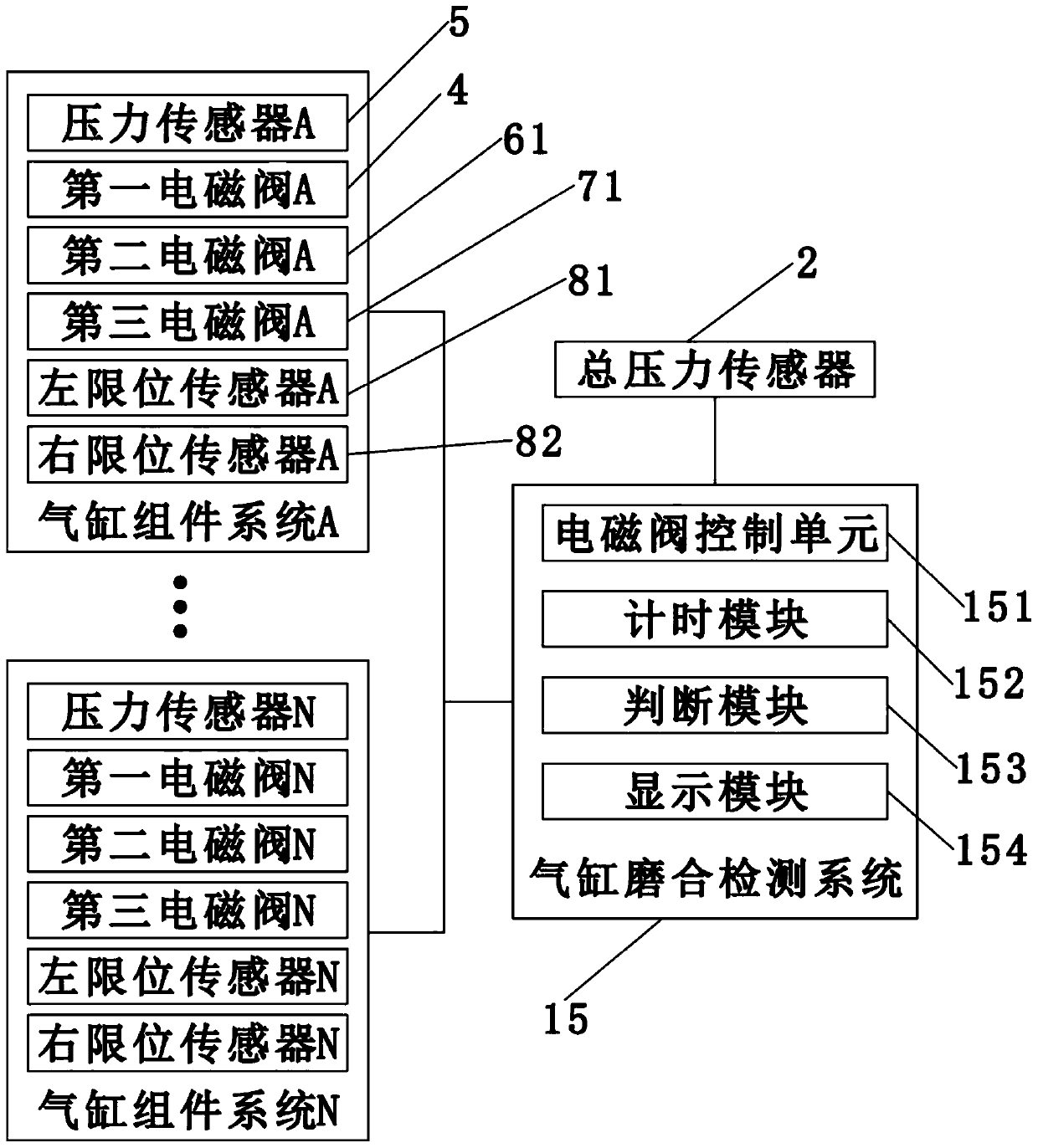

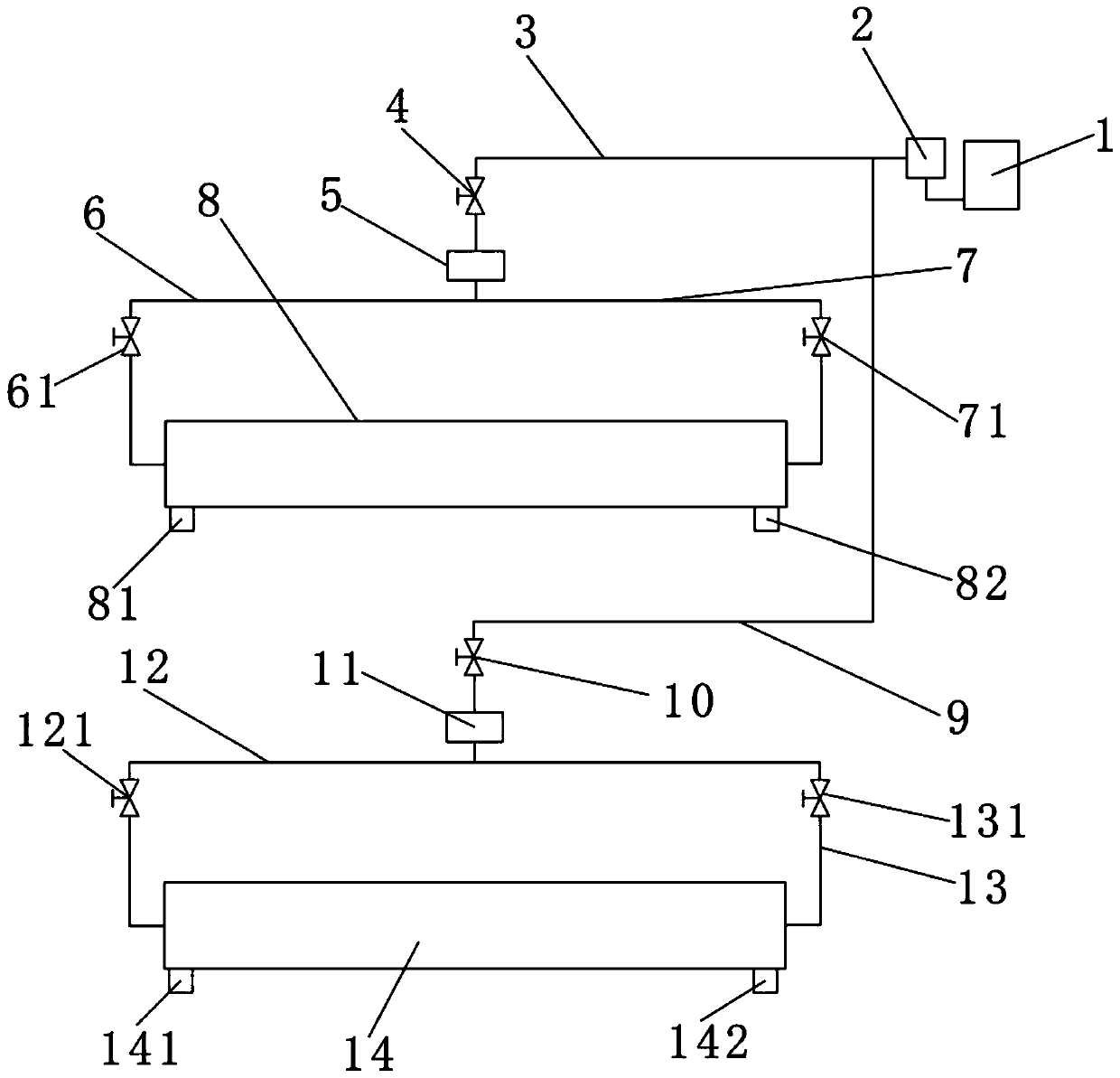

[0043] Such as Figure 2 to Figure 5As shown, a fully automatic running-in detection system for rail transit cylinders includes an air storage tank 1, a total pressure sensor 2, a cylinder running-in detection system 15 and several cylinder assembly systems, and the air storage tank 1 is connected with each cylinder assembly system respectively. The gas outlet end of the gas storage tank 1 is provided with a total pressure sensor 2, and the total pressure sensor 2 is connected with a cylinder running-in detection system 15. The cylinder assembly system includes a gas delivery main pipe, a first branch pipe, a second branch pipe and a cylinder. The air outlet end of the main pipe is airtightly connected with the first branch pipe and the second branch pipe. The air outlet end of the first branch pipe is airtightly connected with the left part of the cylinder. The second solenoid valve is installed, the third solenoid valve is installed on the second branch pipe, the left limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com