Copper precipitation method for economical copper-containing microbiological corrosion resistant pipeline steel

A technology of microbial resistance and pipeline steel is applied in the field of copper-containing microbial corrosion resistant pipeline steel, which can solve the problems of increasing production processes, reducing production efficiency, increasing production costs, etc., and achieving the effect of good microbial corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

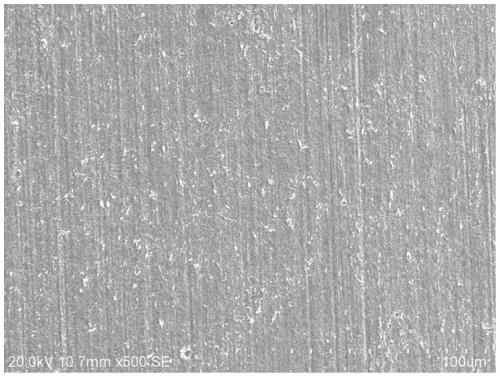

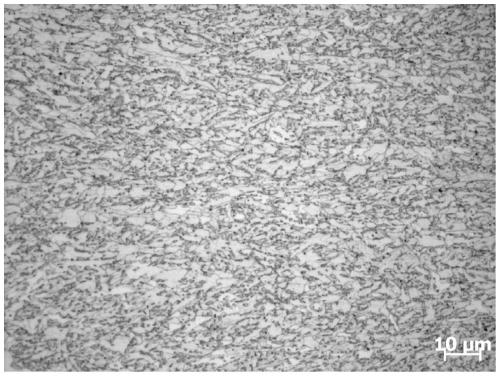

Image

Examples

Embodiment Construction

[0022] The production process of copper-containing microbial corrosion-resistant pipeline steel treated by the above scheme does not require additional aging heat treatment.

[0023] In order to further illustrate the technical means and effects of the present invention to achieve the intended purpose of the invention, an economical copper-containing microbial corrosion-resistant pipeline steel copper precipitation method proposed by the present invention will be described in detail below in combination with examples and comparative examples.

[0024] By weight percentage, the chemical composition of the copper-containing pipeline steel with the same composition used in the embodiment and the comparative example is:

[0025] C: 0.03%; Si: 0.14%; Mn: 0.81%; S: 0.0017%; P: 0.006%; Ni: 0.2%; Cr: 0.08%; Cu: 1.52%; 0.05, V: 0.005; Al: 0.001; Ce: 0.01; the balance is Fe.

[0026] The copper-containing pipeline steel has a hot-rolled cumulative reduction of 90%. The final rolling te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com