A processing method of curved oblique helix skeleton

A technology of oblique helix and processing method, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of restricting magnet processing, difficulty, and high cost, so as to reduce processing costs, prevent stress deformation, and guarantee The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0029] For a specific bending radius such as figure 1 In the design of the curved oblique helix skeleton shown, the material of the skeleton 1-1 is aluminum alloy, and the processing method is as follows.

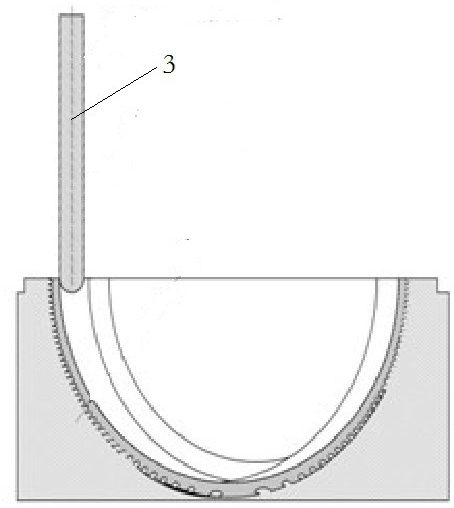

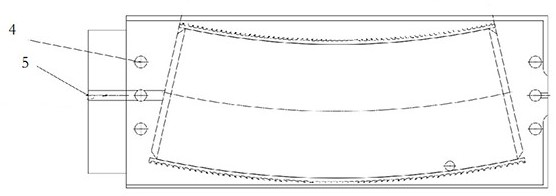

[0030] Step 1: According to the size of the skeleton 1-1, select two appropriate cuboid aluminum alloy materials; Step 2, such as figure 2 , image 3 and Figure 4 As shown, the inner wall surface of the first semi-cylindrical skeleton 2-1 and the inner wall surface of the second semi-cylindrical skeleton 2-2 are processed on the two cuboid materials of step 1 by using the ball end cutter 3 of the CNC machine tool, and Open several bolt holes 4 on two cuboid aluminum alloy materials, and ensure that the finish is higher than 3.2; Figure 5 As shown, in order to make the inner wall surface of the first semi-cylindrical framework 2-1 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com