Forming cylinder, using method of forming cylinder and 3D printer

A molding cylinder and servo motor technology, applied in the field of 3D printing, can solve the problems of low lifting position accuracy and inaccurate position, and achieve the effect of ensuring accuracy, high precision and improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

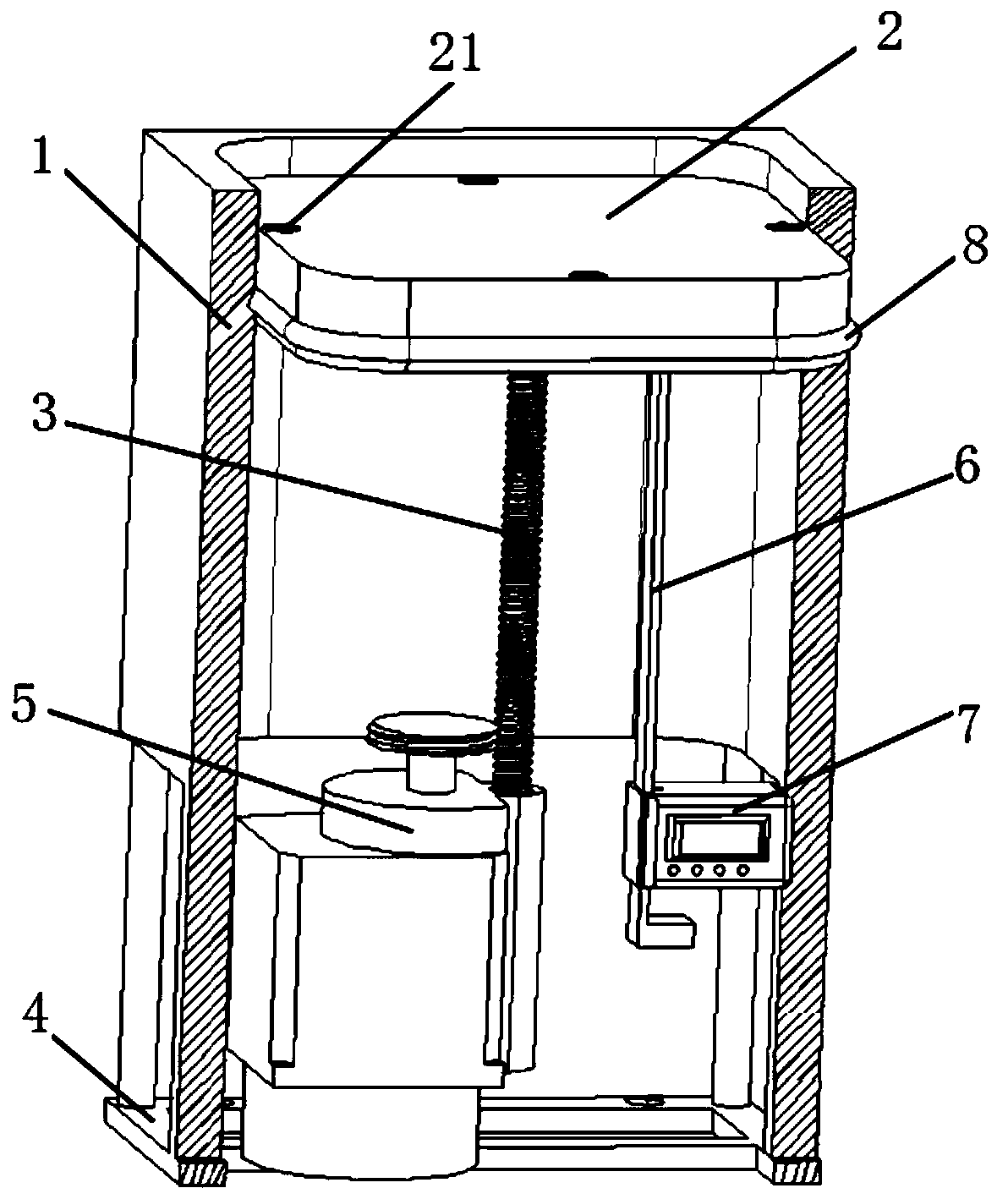

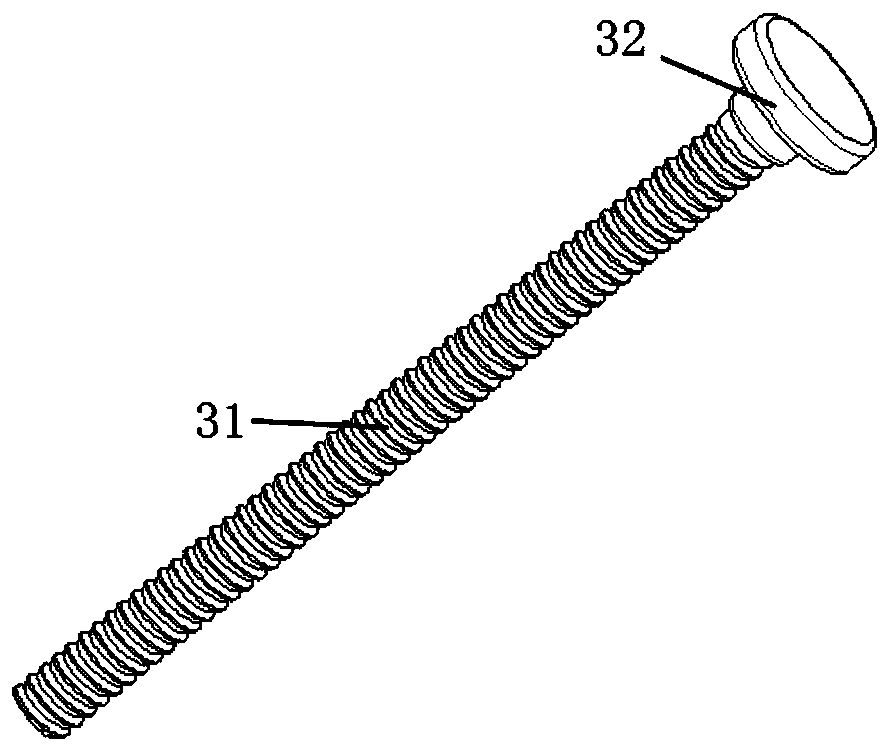

[0037] Reference attached Figure 1-7 As shown, the present invention provides a molding cylinder, including a molding cylinder body 1, a molding substrate base 2, a lifting screw 3, a fixing frame 4, a servo motor 5, a main ruler 6, a position measurement controller 7 and a sealing ring 8 The forming substrate base 2 is sealingly arranged in the forming cylinder body 1, and a sealing ring 8 is arranged between the forming substrate base 2 and the forming cylinder body 1, and the sealing ring 8 adopts a sealing rubber ring.

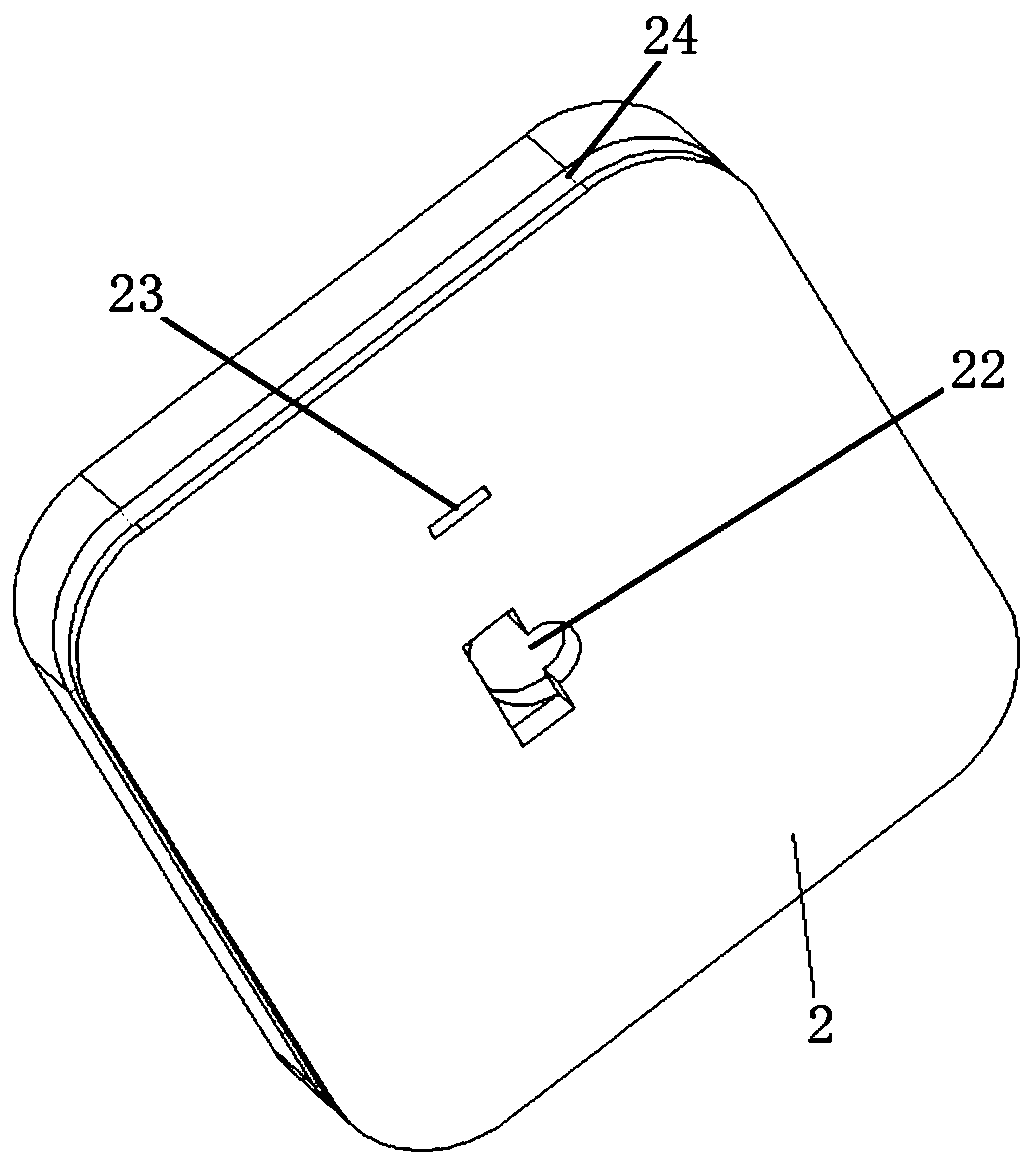

[0038] The molding substrate is arranged on the top of the molding substrate base 2, the molding substrate base 2 adopts a plate structure, the upper surface of the molding substrate base 2 is provided with a substrate fixing screw hole 21, and the molding substrate is connected with the substrate fixing bolt hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com