Automatic cleaning equipment for quartz rods

A self-cleaning, quartz rod technology, applied in lighting and heating equipment, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as easy pollution to the working environment, strong pungent smell, and safety needs to be improved , to achieve the effect of reducing working environment pollution, shortening working hours, and reducing the amount of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0021] Example.

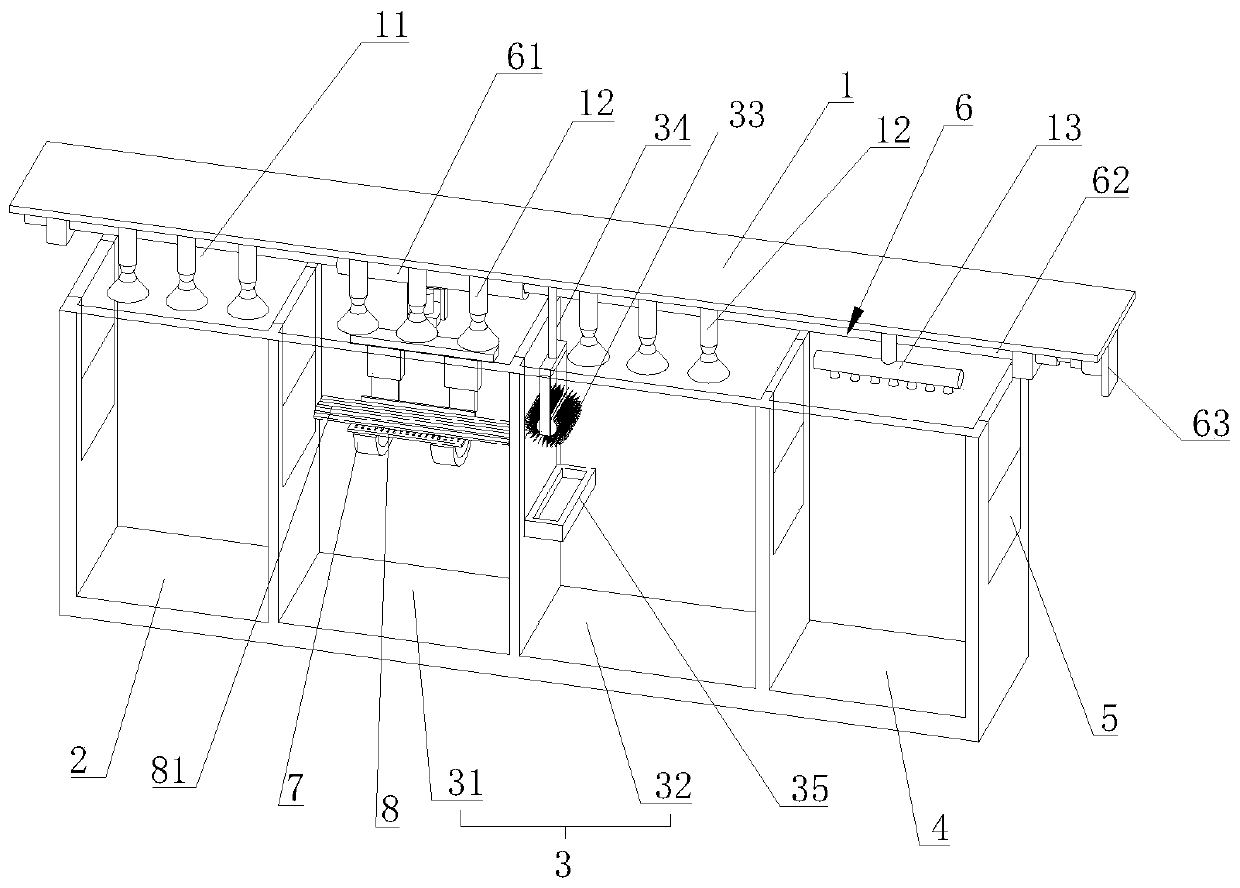

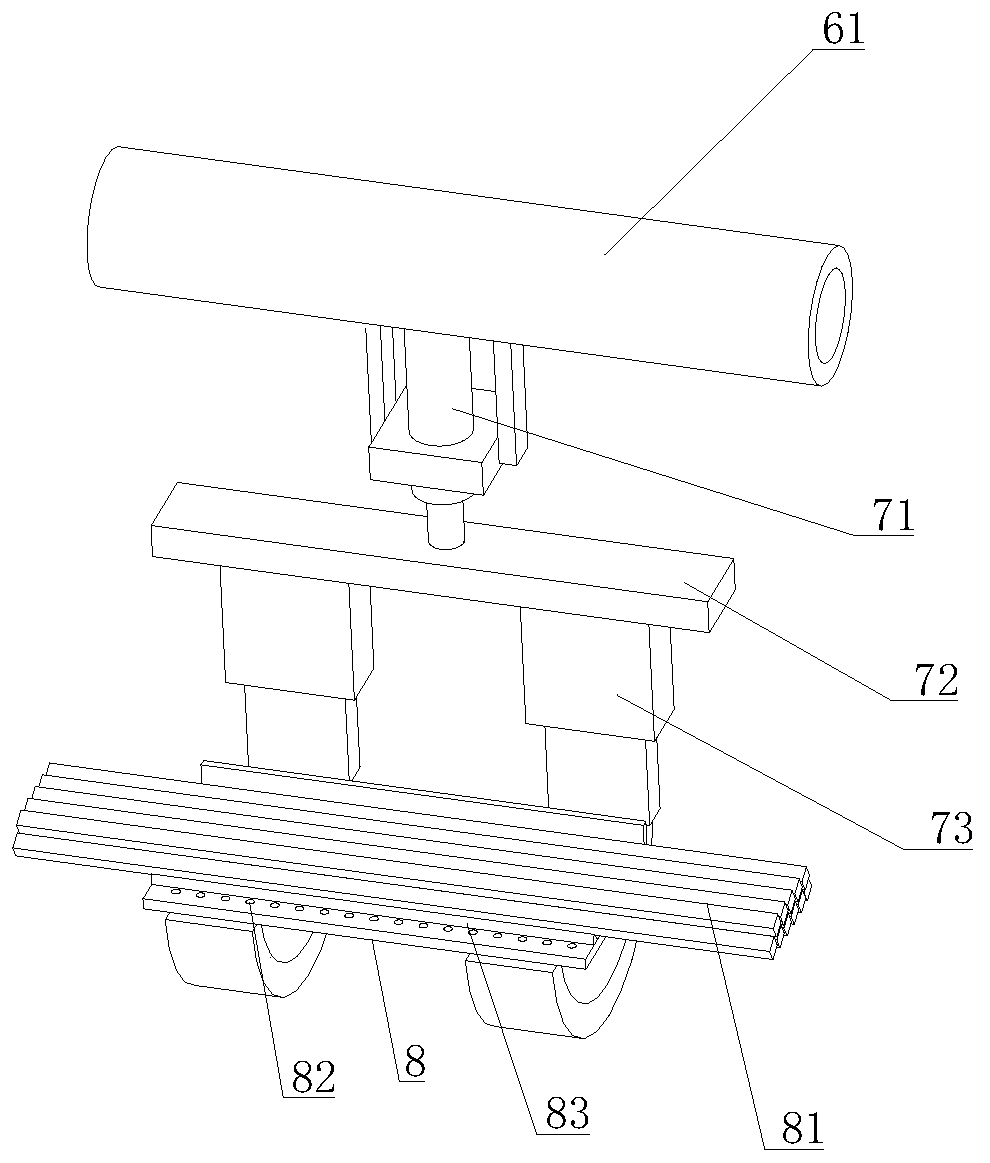

[0022] like Figure 1-4 As shown, a quartz rod automatic cleaning equipment includes a cleaning bracket 1, and a transmission device 6 is arranged on the cleaning bracket 1. The transmission device 6 is connected with a lifting manipulator 7 through a connector 61, and the transmission device 6 drives the lifting manipulator 7 along the cleaning bracket. 1 moves in the length direction, and the lifting manipulator 7 is provided with a filter plate 8 for placing quartz rods 81; the bottom of the cleaning support 1 is sequentially provided with a pickling tank 2, a cleaning tank 3 and a drying tank along the length direction of the cleaning support 1. Pool 4, the outside of pickling pool 2, cleaning pool 3 and drying pool 4 are all equipped with sensing windows 5 for lifting manipulator 7 to pass through.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com