Permeable membrane assembly capable of reducing driving pressure

A technology of permeable membranes and components, which is applied in the field of filter membrane manufacturing. It can solve the problems of relatively high anti-compression performance of membrane components, difficulty in cleaning and recovery, and increased membrane fouling, so as to slow down the difficulty of cleaning and recovery, reduce the driving force, and slow down The effect of membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

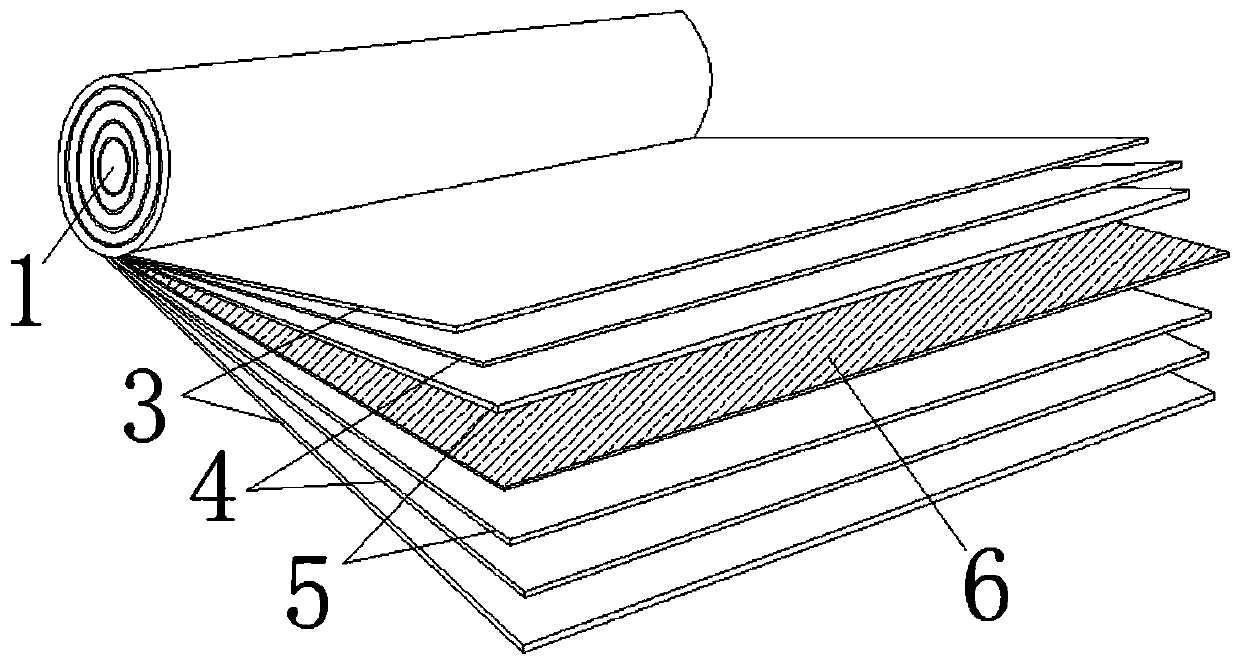

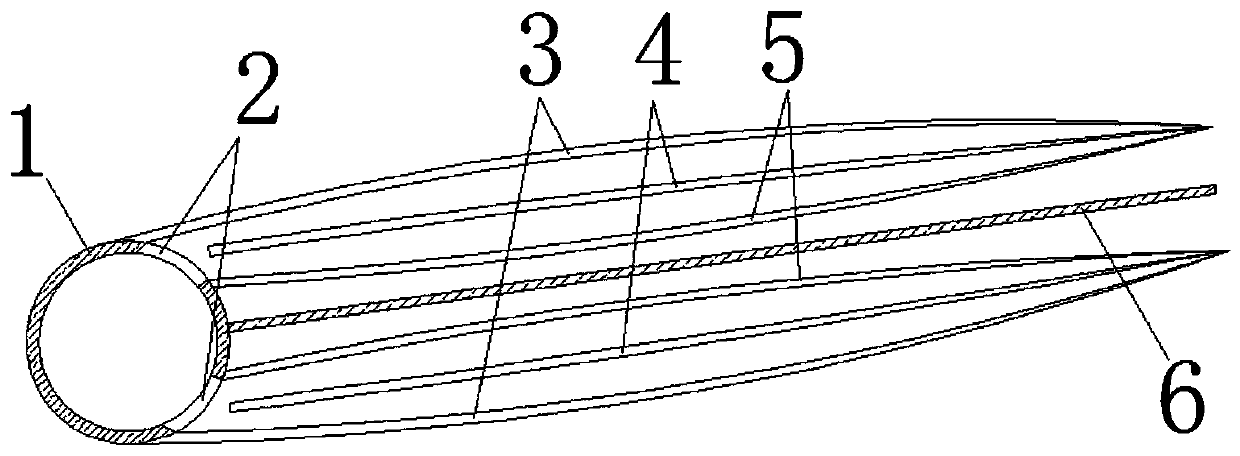

[0014] refer to Figure 1-2 , a osmotic membrane assembly for reducing driving pressure, including a permeate central tube 1 and a plurality of membrane units, a plurality of separation membranes are arranged alternately, two different adjacent membrane units form a filter bag unit, and the membrane unit includes a first The membrane 3 and the second membrane 5, the first membrane 3 and the second membrane 5 are respectively one of ultrafiltration membrane, nanofiltration membrane or reverse osmosis membrane, and the first membrane 3 and the second membrane The types of 5 are different. The combination of the first diaphragm 3 and the second diaphragm 5 can achieve a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com