Shoetree automatic scanning device and working method thereof

A technology for scanning devices and shoe lasts, which is applied to measuring devices for feet or shoe lasts, shoe lasts, and footwear. It can solve problems such as shoe last shaking, affecting shoe last scanning accuracy, and shoe last scanning efficiency. The structure design is simple and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

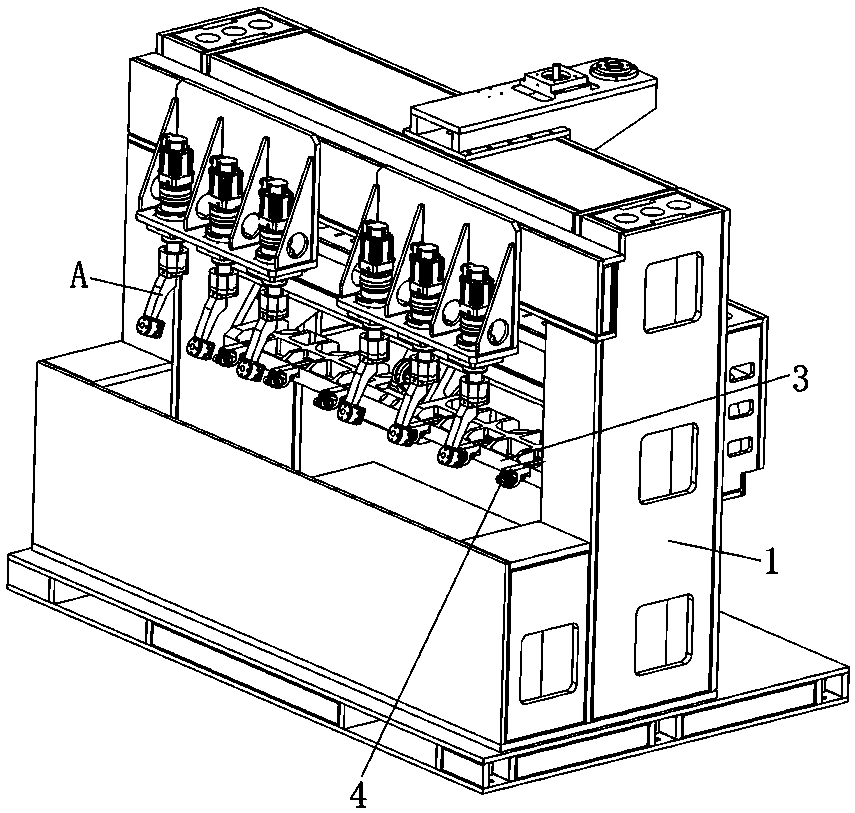

[0046] Embodiment 2: The machine platform is provided with a shoe last cylinder mouth clamping mechanism for clamping the shoe last to be processed, and the shoe last cylinder mouth clamping mechanism A includes a clamping arm A1 and a clamping arm located at the free end of the clamping arm. A hydraulic cylinder A2 whose axis line forms a certain angle with the length direction of the clamping arm. The hydraulic cylinder A2 is provided with a reciprocating piston A3 that moves along the axis line of the hydraulic cylinder. The lower end of the hydraulic cylinder A2 is fixed with a lower end The cover A4 is provided with a jaw A5 for clamping the dovetail groove of the shoe last to be processed. On both sides of the jaw A5, there are a set of sliders A6 that can slide back and forth along the axis of the jaw. The reciprocating piston The lower end surface of the hydraulic cylinder contacts the upper part of the slider A6 through the movable push rod A7 which is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com