Full-sealed plant nutrient aeroponic cultivation device and plant aeroponic cultivation method thereof

A fully sealed and nutritious technology, applied in the field of plant aeroponics, can solve the problems of easy spread of diseases and insect pests, waste of gas in the aeroponic box, incomplete plant nutrition, etc., and achieve the effect of comprehensive plant nutrition and beneficial plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

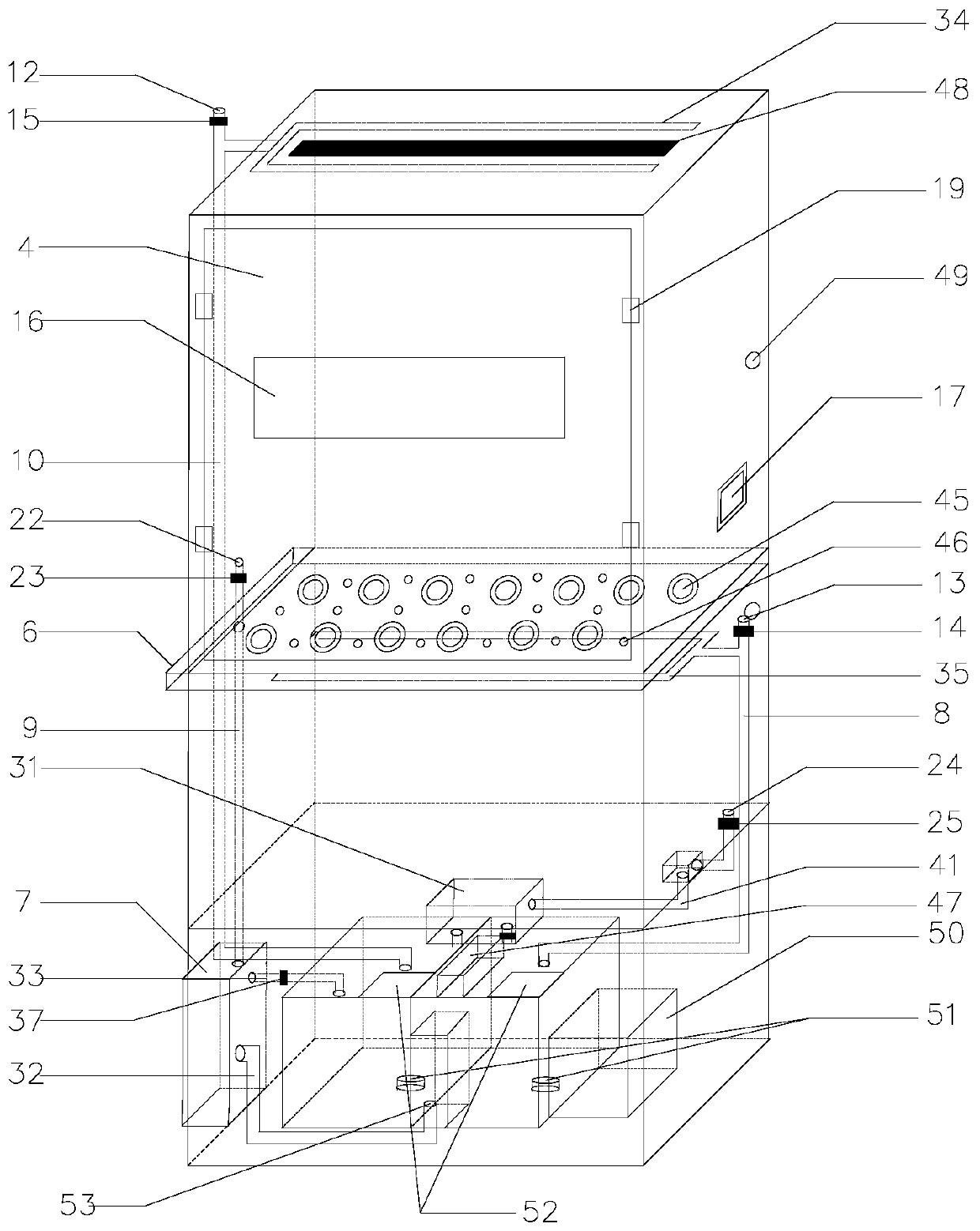

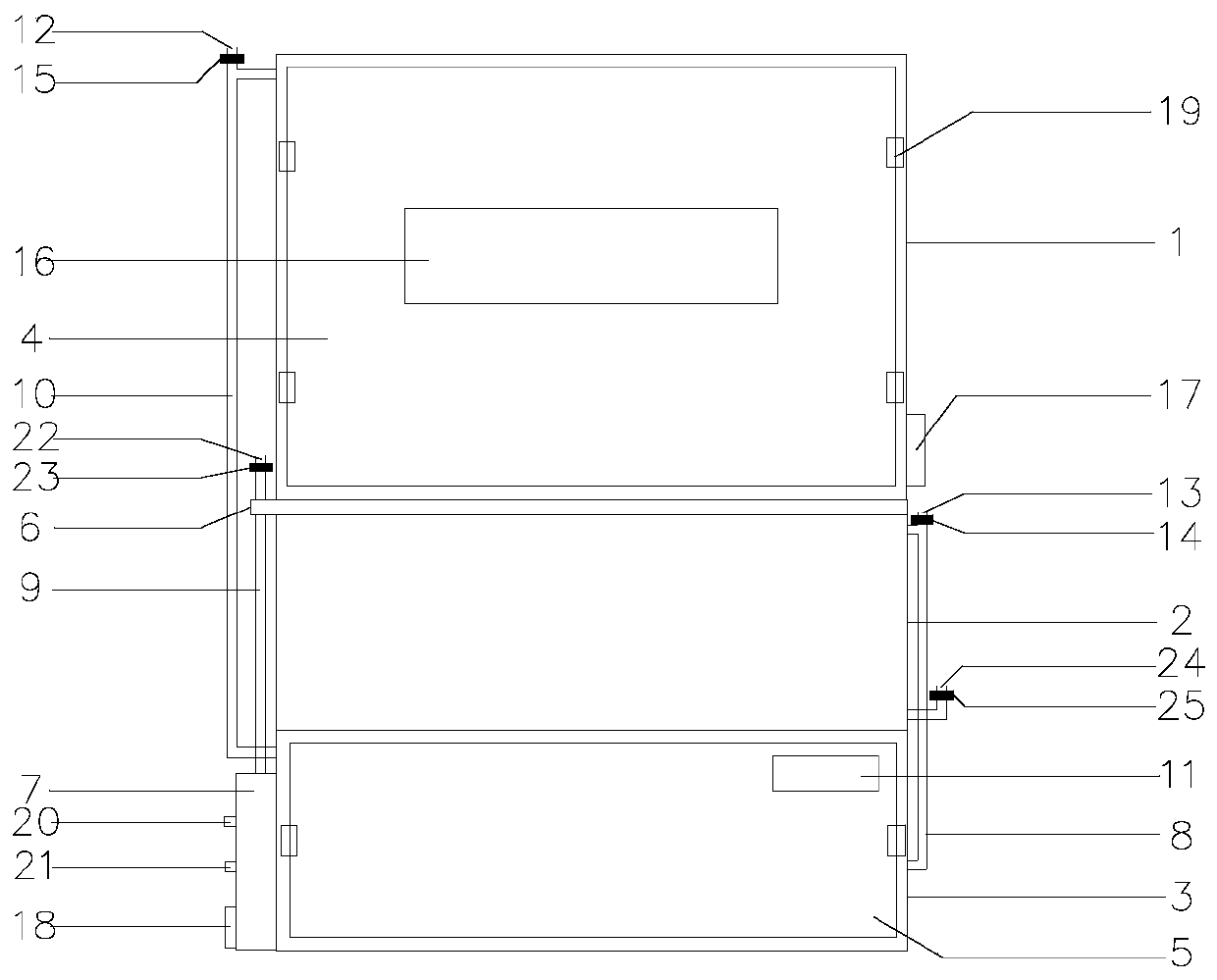

[0063] Such as figure 1 and figure 2 As shown, the fully-sealed plant nutrient fog culture device includes a fog culture box and a cultivation plate 6 located in the fog culture box, and the fog culture box is separated into the photosynthetic fog culture box 1 above and the lower one by the cultivation plate 6. The rhizosphere mist cultivation box 2, the photosynthetic mist cultivation box 1 is provided with the photosynthetic nutrient mist spray pipe 34 that can eject the nutrient mist required by the stems and leaves, and the rhizosphere mist cultivation box 2 is provided with the The rhizosphere nutrient mist nozzle 35 that needs nutrient mist, the photosynthetic mist incubator 1 is provided with a hermetic door for sealing and is provided with an LED light 48 at the top.

[0064] The photosynthetic mist cultivation box 1 includes an airtight door 4, which is fixed on the photosynthetic mist cultivation box 1 by a buckle 19, which can be opened during planting, harvestin...

Embodiment 2

[0073] Such as Figure 6 As shown, the difference of this embodiment is that the cultivation plate 6 is a double-layer sealed hollow plate made of hard plastic, and the photosynthetic nutrient mist return hole 46 is arranged on the upper layer of the sealed hollow plate and does not pass through the The cultivation plate 6, the cultivation hole runs through the cultivation plate 6 and the plant cultivation fixing bowl 44 is placed in the plant cultivation hole 45 to seal the plant cultivation hole 45 so as to realize the isolation of the upper and lower boxes.

[0074] The cultivation plate 6 is inclined downward from the end far away from the photosynthetic nutrient mist return pipe 9 to the end connected with the photosynthetic nutrient mist return pipe 9. The photosynthetic nutrient solution flows into the photosynthetic nutrient mist return pipe 9 for recycling.

[0075] The degree of sealing of the cultivation plate 6 has determined the isolation degree of the photosynth...

Embodiment 3

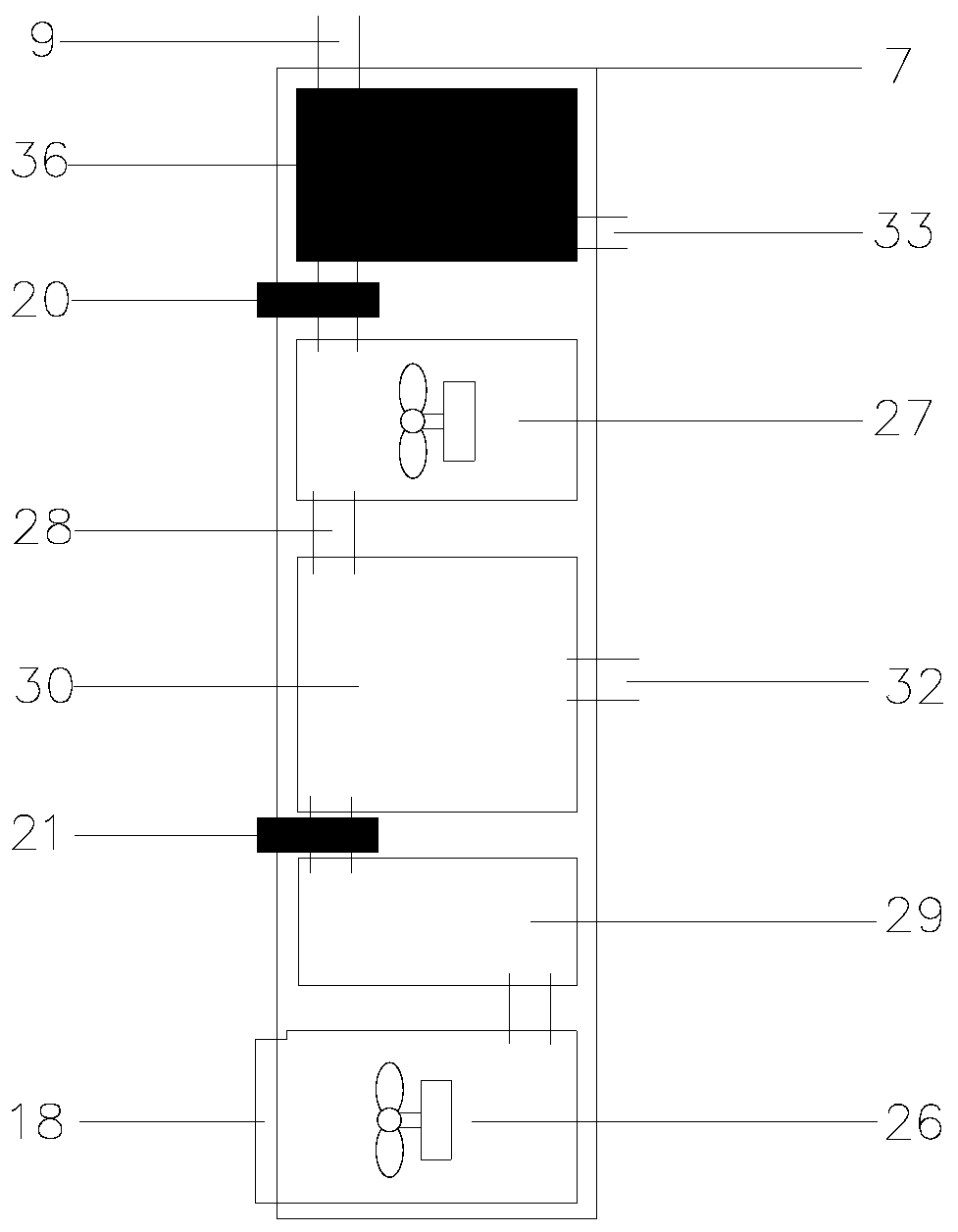

[0078] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 2 is that a gas circulation module is also provided below the fully sealed plant nutrition aeroponics device, and the gas circulation module includes an air supply module 7 and a first gas-liquid separation module 31. The air supply module 7 is connected with the rhizosphere nutrient solution atomization box 39, the inlet of the first gas-liquid separation module 31 is connected with the rhizosphere nutrient mist return pipe 41, and the air-liquid separation module 31 of the first The liquid output port is connected to the rhizosphere nutrient solution atomization box 39 through the rhizosphere nutrient mist droplet collection pipe 42, and a first check valve 38 is arranged between them to prevent the aerosol from flowing backward. The first gas-liquid separation module 31 The gas output port is connected to the photosynthetic nutrient solution atomization box 40 through the air internal c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com