Combined type large-temperature-difference cold supply system and control method thereof

A large temperature difference, compound technology, used in air conditioning systems, heating methods, household heating and other directions, can solve the problem of small temperature difference between supply and return water, large temperature difference and the energy saving and cost saving advantages of cold storage technology have not been fully exerted, cold storage device cold storage density It can not be improved and other problems, so as to achieve the effect of increasing the density of cold storage, broadening the temperature limit, reducing the initial investment of equipment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

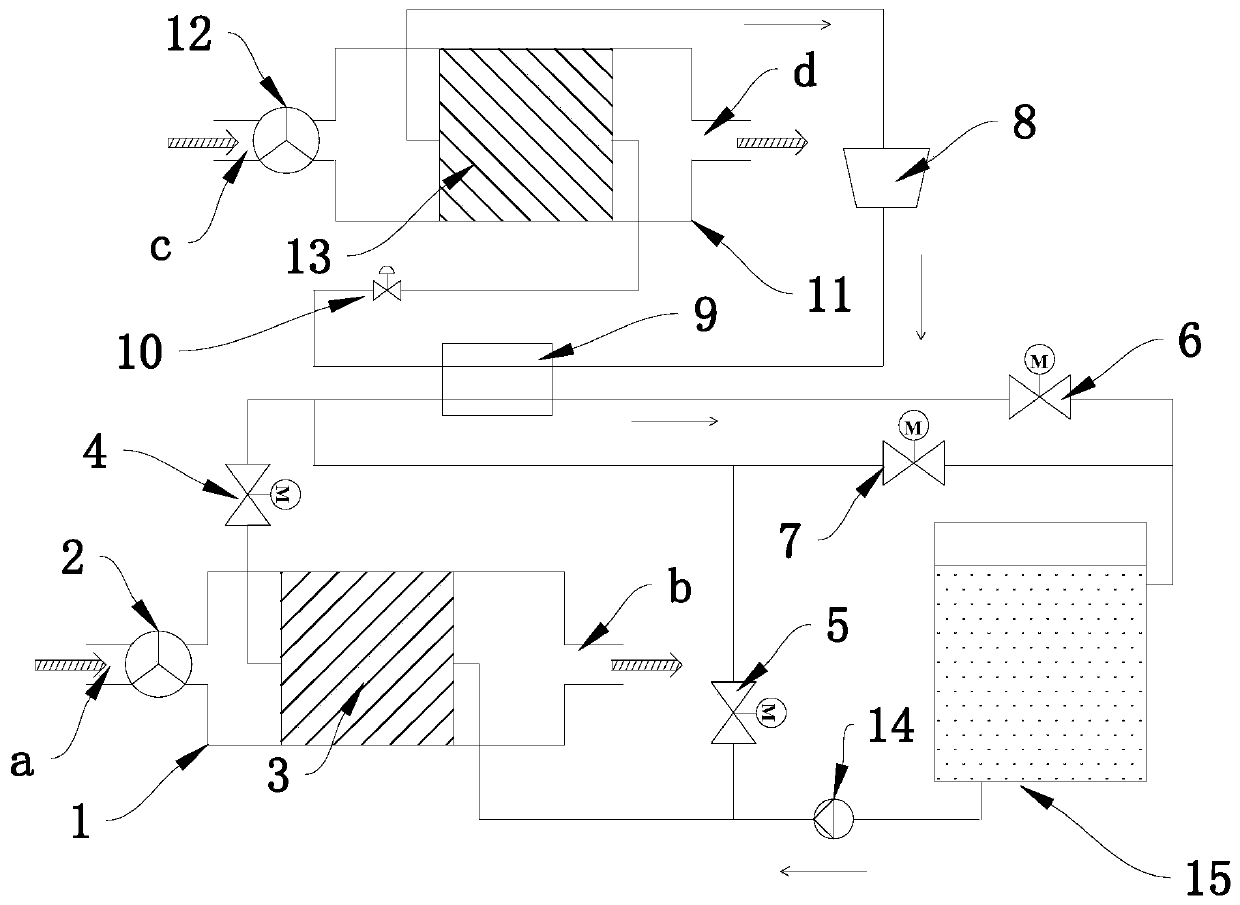

[0047] Such as figure 1 As shown, in the combined cooling mode: turn on the cooling water pump 14, the first fan 2, the compressor 8, the throttling device 10, the second fan 12, the first valve 4 and the third valve 6, and close the second valve 5 and the fourth valve 7; the low-temperature cold water stored in the cold storage device 15 enters the first heat exchange module 3 to exchange heat with the air in the first wind cabinet 1 to form medium-temperature cold water, and the cooled air is sent to the user end by the first fan 2, The formed medium-temperature cold water enters the condenser 9 and exchanges heat with the high-temperature and high-pressure refrigerant gas from the compressor 8 to form high-temperature cold water. The refrigerant gas-liquid mixture enters the second heat exchange module 13 and the air in the second wind cabinet 11 performs heat exchange and evaporation to form a low-pressure refrigerant gas and returns to the compressor 8, and the cooled air...

Embodiment 2

[0049] Such as figure 1 As shown, in the independent cooling mode of the first wind cabinet: turn on the cooling water pump 14, the first fan 2, the first valve 4 and the fourth valve 7, turn off the compressor 8, the throttling device 10, the second fan 12, The second valve 5 and the third valve 6; the low-temperature cold water stored in the cold storage device 15 enters the first heat exchange module 3 to exchange heat with the air in the first wind cabinet 1 to form medium-temperature cold water, and the cooled air is sent by the first fan 2 To the user end, the formed medium-temperature cold water returns to the cold storage device 15 for use.

Embodiment 3

[0051] Such as figure 1 As shown, in the independent cooling mode of the second wind cabinet: turn on the cooling water pump 14, the compressor 8, the throttling device 10, the second fan 12, the second valve 5 and the third valve 6, and turn off the first fan 2, The first valve 4 and the fourth valve 7; the medium-temperature cold water stored in the cold storage device 15 in the independent cooling mode of the first wind cabinet is transported to the condenser 9 through the cooling water pump 14, and the high-temperature and high-pressure refrigerant gas from the compressor 8 Perform heat exchange to form high-temperature cold water, high-temperature and high-pressure refrigerant gas condenses into high-temperature and high-pressure refrigerant liquid, throttling and reducing pressure through the throttling device 10 to form a low-pressure refrigerant gas-liquid mixture, and enters the second heat exchange module 13 and the second wind cabinet 11 The air is heat-exchanged an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com